Al-Si-Fe-RE-B alloy conductor material and preparing method thereof

A conductor material, al-si-fe-re-b technology, applied in the direction of metal/alloy conductors, conductive materials, conductive materials, etc., can solve problems such as elastic modulus that are not involved, achieve the suppression of shrinkage and shrinkage, High elastic modulus, the effect of improving elastic modulus and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The technical solutions of the present invention will be further explained below through specific embodiments. The embodiments are only to help understand the present invention and should not be regarded as specific limitations to the present invention.

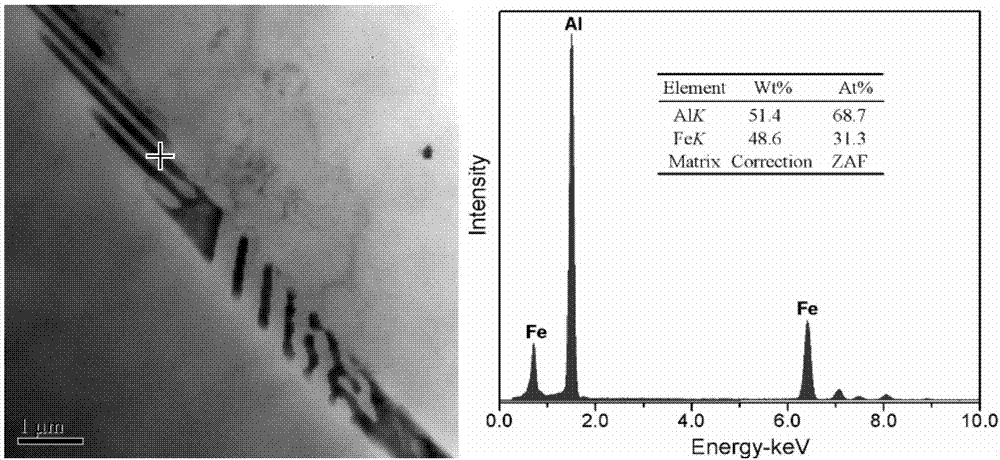

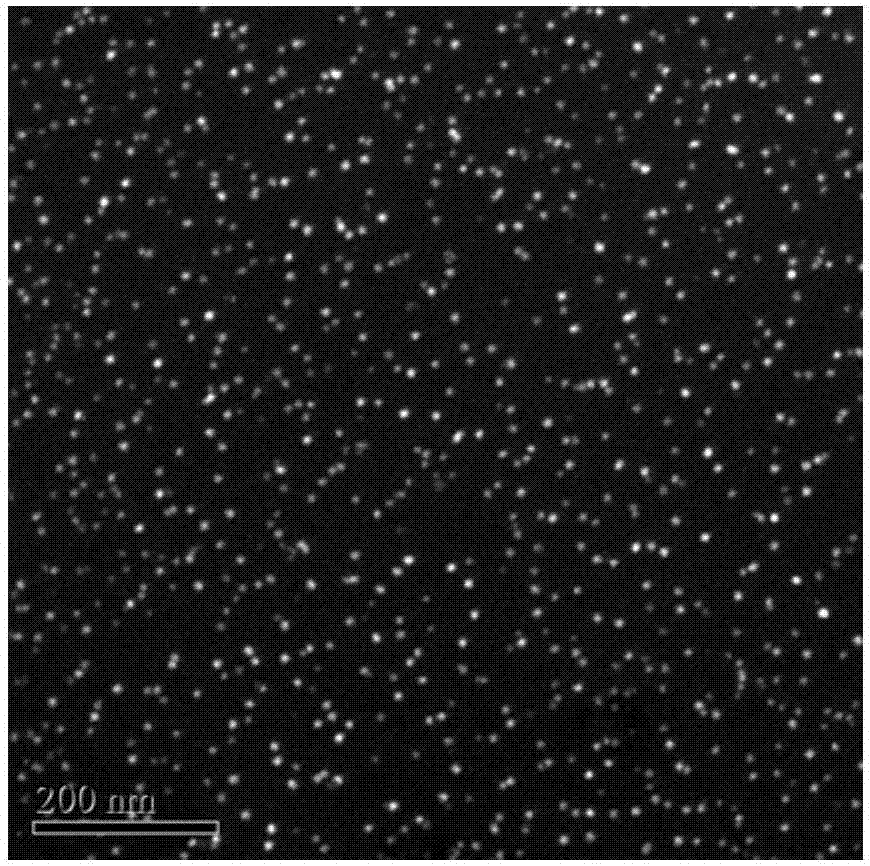

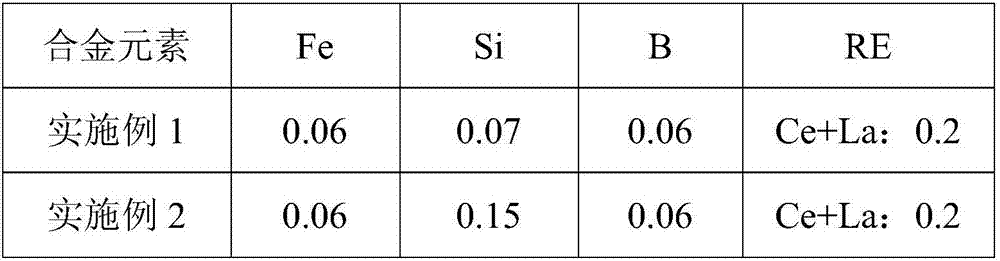

[0036] The compositions of Examples 1-9 and Comparative Examples 1-10 (wherein Comparative Example 10 is 99.7% industrial pure aluminum) are shown in Table 1. Using industrial pure aluminum ingots with a purity of 99.7% (wherein Si is 0.05wt%, Fe is 0.13wt%, Cu is 0.01wt%, and Mg is 0.01wt%), after melting industrial pure aluminum at 760-780℃, add B , RE element, when the content of Si and Fe in the industrial pure aluminum ingot or electrolytic aluminum liquid is lower than the design content of the corresponding Si and Fe element (compared to the same element), add this element, then refining and furnace front Quick composition analysis and composition adjustment, so that the content of each alloy element is the design ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com