Bamboo pulp dispersible spunlace material and production method

A production method and technology of bamboo pulp, applied in the direction of textiles and papermaking, non-woven fabrics, absorbent pads, etc., can solve the problems of reduced dispersion performance and low production cost, and achieve the goal of simplifying the process, meeting market demand, and sufficient raw material sources Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

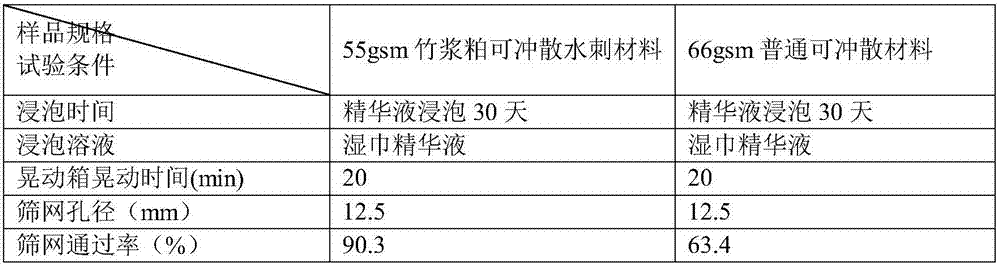

Examples

Embodiment 1

[0051] A bamboo pulp spunlace material with a mass per unit area of 55g / m 2 , including the raw materials of the following mass percentages: 60% natural bamboo pulp (the degree of knocking after disc grinding is 13 ° SR, the fiber length in the pulp is 1.8 ~ 2.4 mm, the fineness is 11 ~ 16 μ m, the fiber cross section elliptical hollow), 20% wood pulp, 20% artificial cellulose fibers (viscose fibers with a length of 5-12 mm and a fiber fineness of 0.1-3.3 dtex).

[0052] The preparation method of the described bamboo pulp flushable spunlace material comprises the following steps:

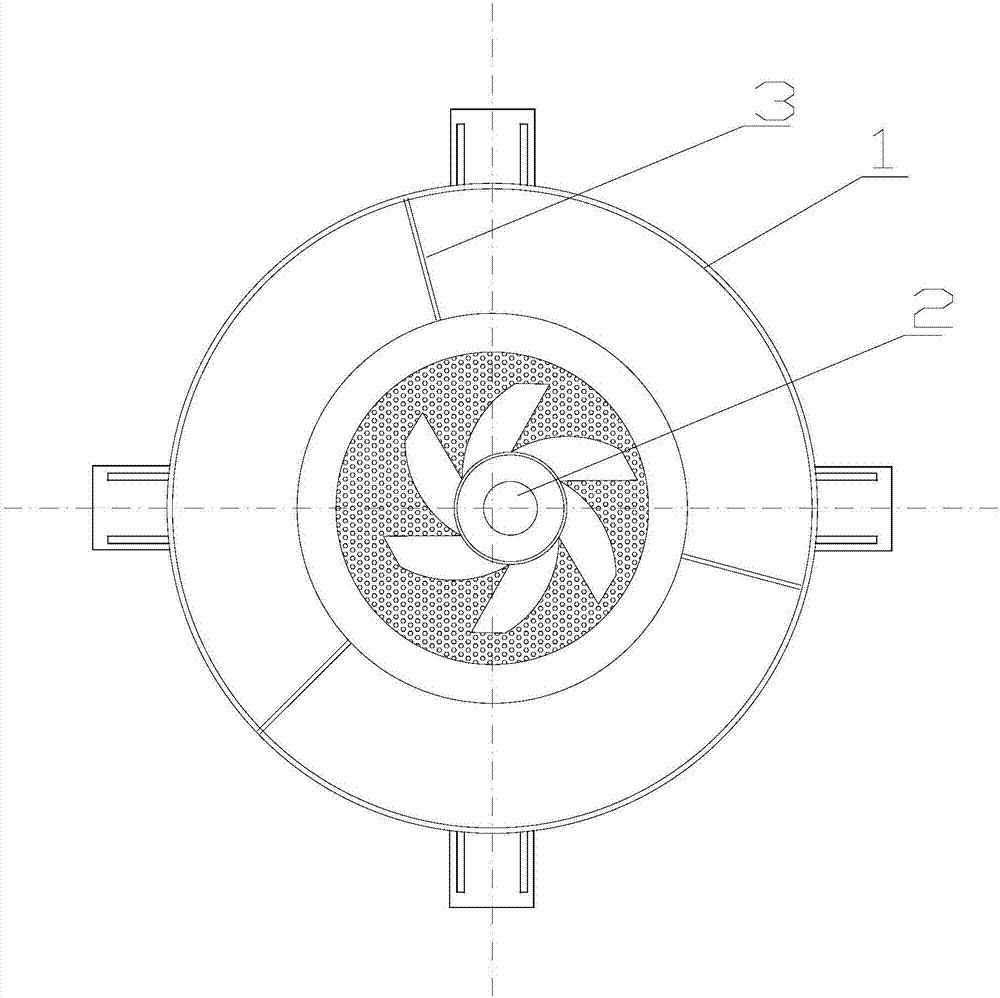

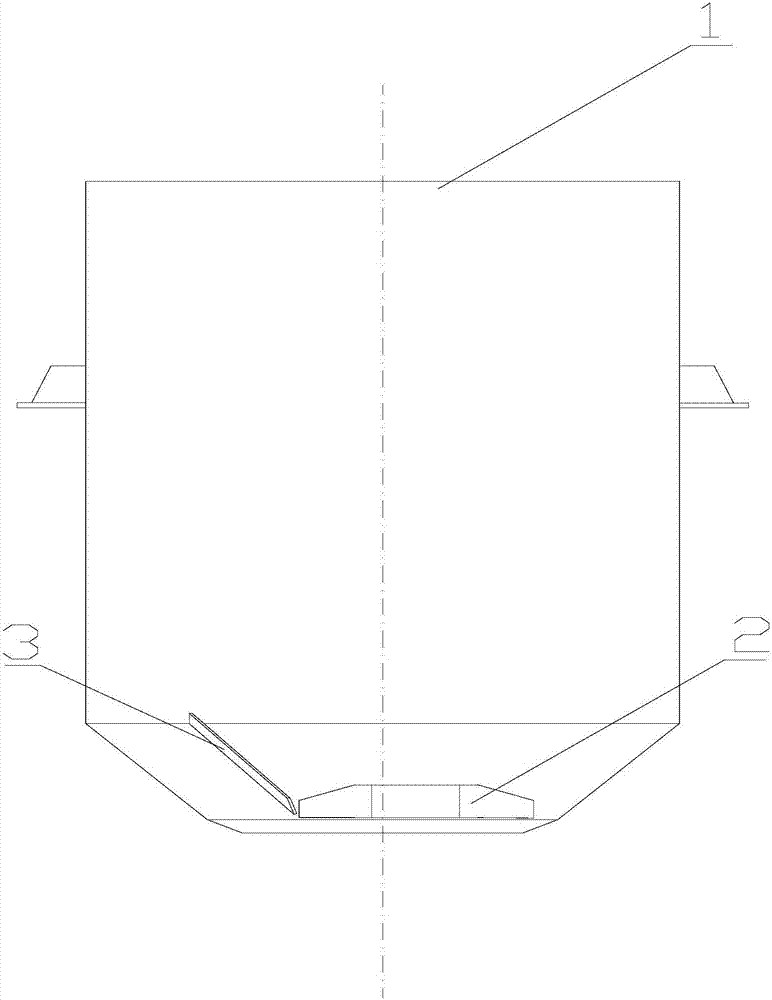

[0053] 1) Add the bamboo pulp and wood pulp into the crushing tank with the baffle plate according to the ratio, and the bamboo pulp and the wood pulp are crushed by the rotation of the eccentric rotor in the pulping tank, and then after many One disc grinding process (the multi-channel disc grinding process is specifically: using three disc grinding processes, the slurry first passes through a c...

Embodiment 2

[0059] A bamboo pulp spunlace material with a mass per unit area of 40g / m 2 , including the raw materials of the following mass percentages: 10% natural color bamboo pulp (the degree of knocking after disc grinding is 12 ° SR, the fiber length in the pulp is 1.8 ~ 2.4 mm, the fineness is 11 ~ 16 μ m, the fiber cross section elliptical hollow), 60% wood pulp, 30% artificial cellulose fiber (bamboo fiber with a length of 5-12 mm and a fiber fineness of 0.1-3.3 dtex).

[0060] The preparation method of the described bamboo pulp flushable spunlace material comprises the following steps:

[0061] 1) Add the bamboo pulp and wood pulp into the crushing tank with the baffle plate according to the ratio, and the bamboo pulp and the wood pulp are crushed by the rotation of the eccentric rotor in the pulping tank, and then after many One disc grinding process (multi-channel disc grinding process is specifically: using three disc grinding processes, the slurry first passes through a co...

Embodiment 3

[0066] A bamboo pulp spunlace material with a mass per unit area of 80g / m 2 , including the raw materials of the following mass percentages: 80% natural color bamboo pulp (the degree of knocking after disc grinding is 14 ° SR, the fiber length in the pulp is 1.8 ~ 2.4 mm, the fineness is 11 ~ 16 μ m, the fiber cross section elliptical hollow), 20% artificial cellulose fibers (tencel fibers with a length of 5-12 mm and a fiber fineness of 0.1-3.3 dtex).

[0067] The preparation method of the described bamboo pulp flushable spunlace material comprises the following steps:

[0068]1) Add the bamboo pulp and wood pulp into the crushing tank with the baffle plate according to the ratio, and the bamboo pulp and the wood pulp are crushed by the rotation of the eccentric rotor in the pulping tank, and then after many One disc grinding process (the multi-channel disc grinding process is specifically: using three disc grinding processes, the slurry first passes through a coarse disc ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Knocking degree | aaaaa | aaaaa |

| Fiber length | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com