Coal-mine underground-adit directional drilling machine

A technology for directional drilling rigs and tunnels, applied in the direction of drill pipes, drill pipes, drilling equipment, etc., can solve the problem that the structure design, stability, reliability and power of directional drilling rigs cannot meet the requirements of directional drilling rigs, and the geological mining of deep coal seams is difficult, Reduce product reliability and other issues, achieve good space utilization efficiency, optimize structural layout, and increase stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings.

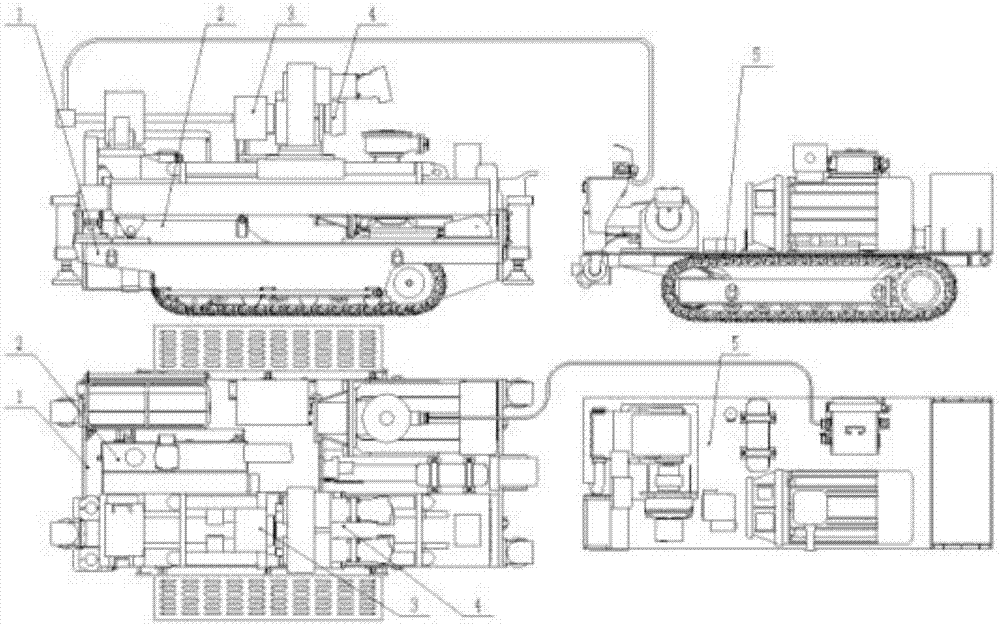

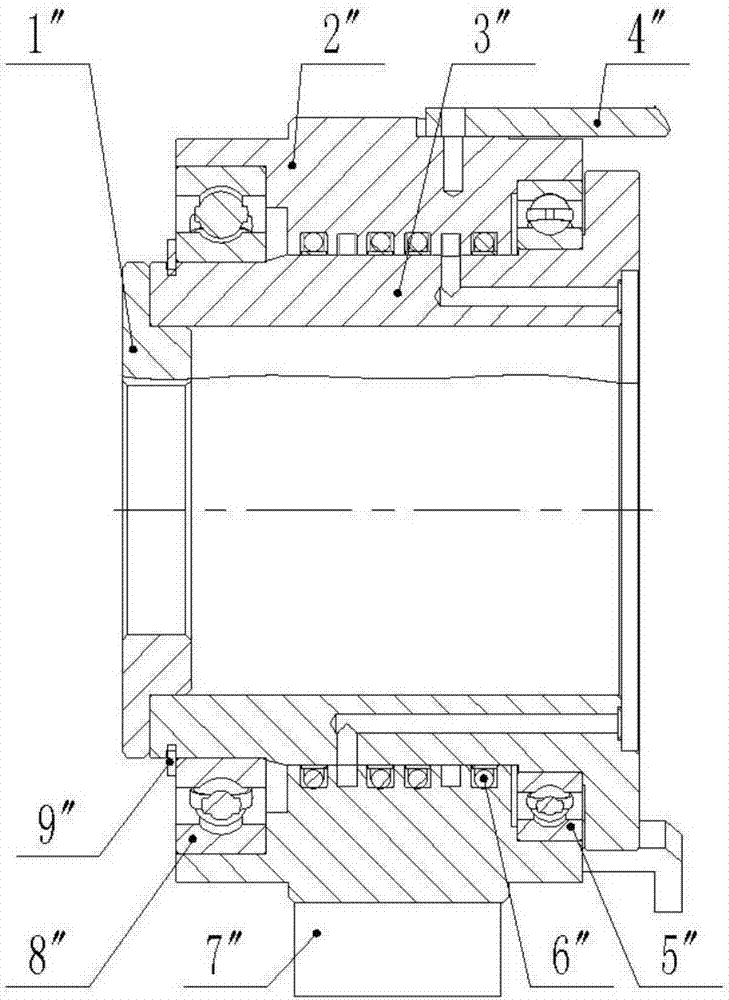

[0031] As shown in Fig. 1, it is a schematic structural view of the coal mine tunnel directional drilling machine of the present invention, which includes a drilling car 1 and a pump car 5. The drilling rig 1 includes an oil tank 2 , a rear clamping portion 3 and an oil distribution sleeve 4 .

[0032] As an embodiment, the pump truck 5 can also be integrated with the drilling truck 1 according to actual conditions.

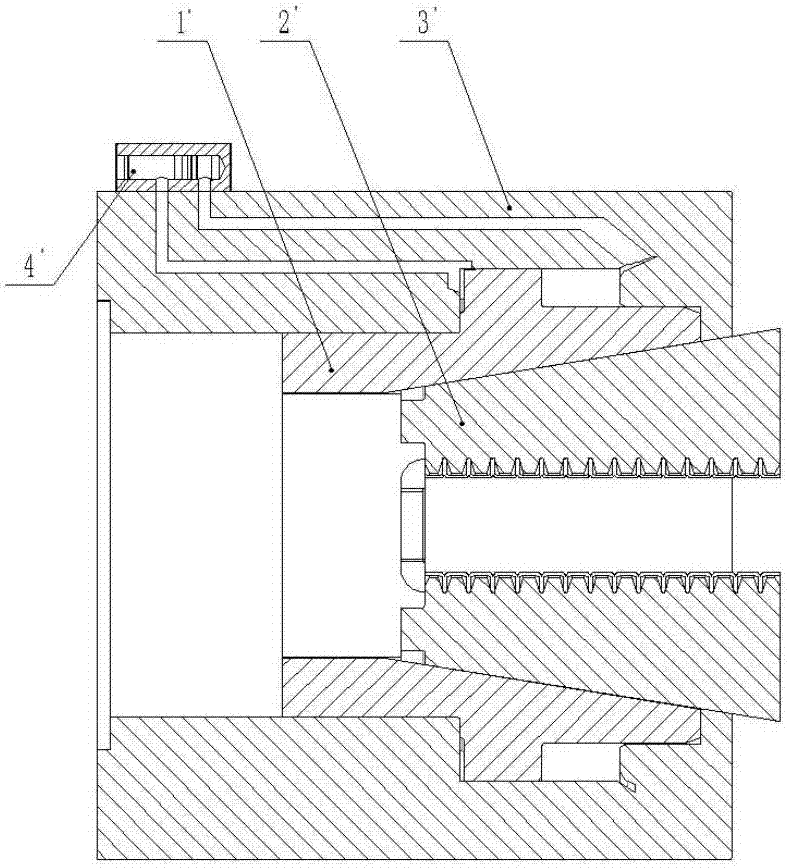

[0033] In the structure of directional drilling rig, due to the large volume of the hydraulic oil tank, it needs to occupy more space, but the space of the underground tunnel is generally relatively narrow, and the requirements for the size of the equipment are relatively strict, so the structure of the oil tank greatly affects the setting of other components and various pipes. Therefore, the present invention adopts that the fuel tank 2 is submerged and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com