Manual control valve of harvester

A manual control and harvester technology, which is applied in the hydraulic field, can solve problems affecting control stability and accuracy, insufficient supply of hydraulic oil pressure changes, unstable oil pressure of control oil, etc., to achieve long speed regulation area and improve stability , the effect of reducing pressure loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

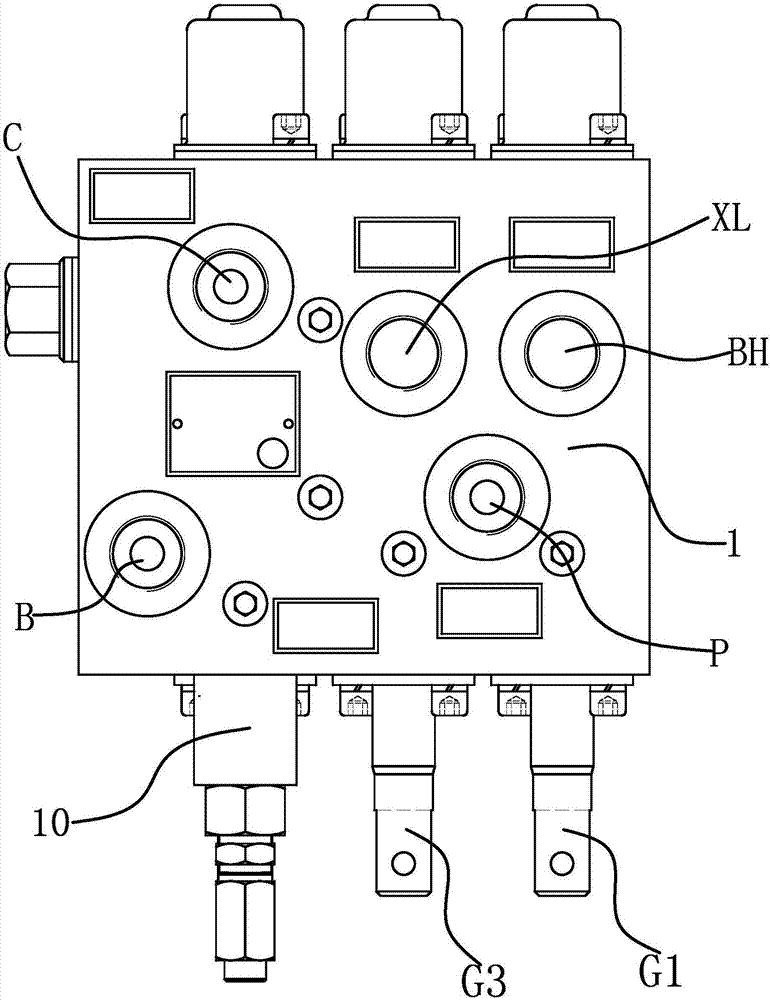

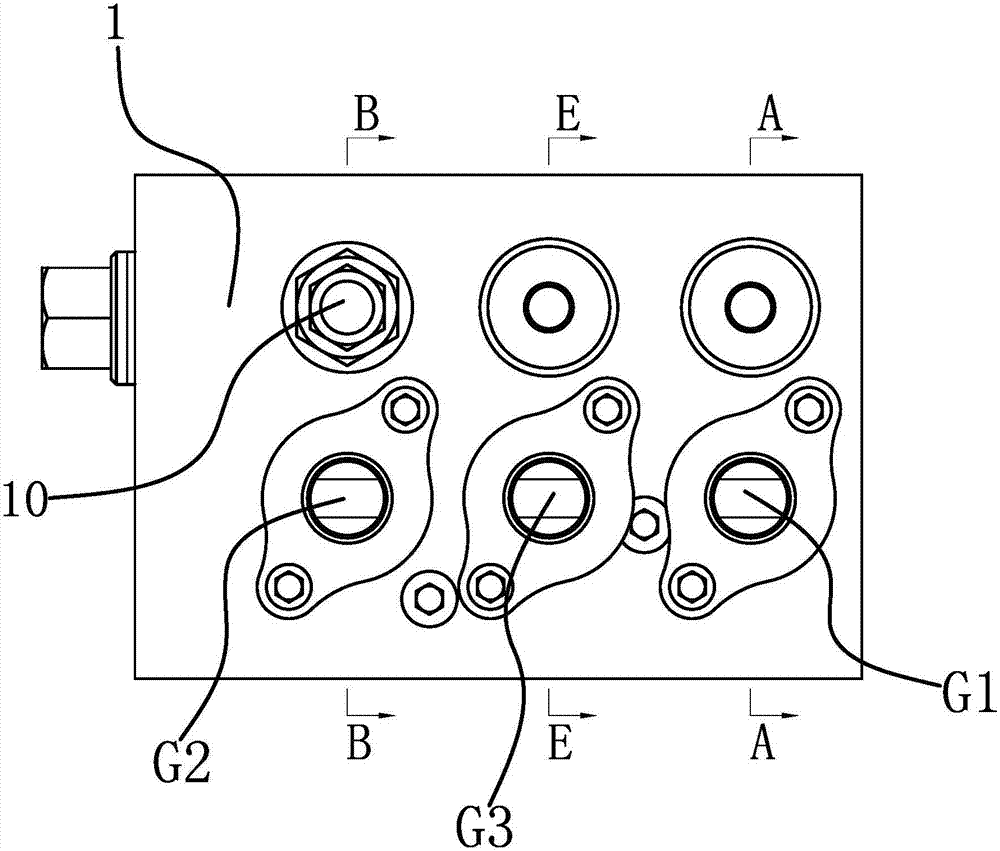

[0036] The harvester manual control valve includes valve body 1, reversing control valve 1 2, reversing control valve 2 3, oil inlet P, oil return port T, control oil port 1 BH, control oil port 2 A, control oil port Three B and transfer oil port C.

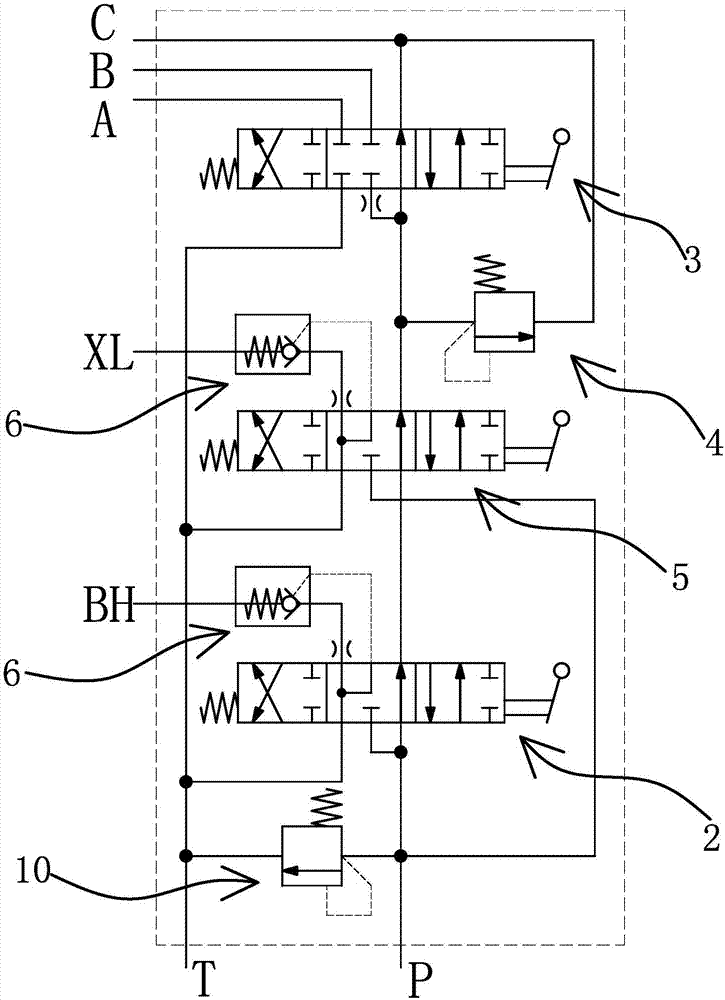

[0037] In this embodiment, the manual control valve for controlling the lifting of the reel, the lifting of the unloading barrel and the rotation of the gun barrel is taken as an example to introduce the specific implementation of the manual control valve of the harvester. Such as figure 1 As shown, the harvester manual control valve also includes a reversing control valve three 5, and the valve body 1 also has a control oil port four XL. The reversing control valve 1 2, re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com