Spout swinging mechanism

A swing mechanism and nozzle technology, applied in the field of boilers, can solve the problems of wind box design constraints, limited nozzle height, shortened connecting rod life and other problems, and achieve the effects of high reliability, fewer connecting parts, and reduced force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

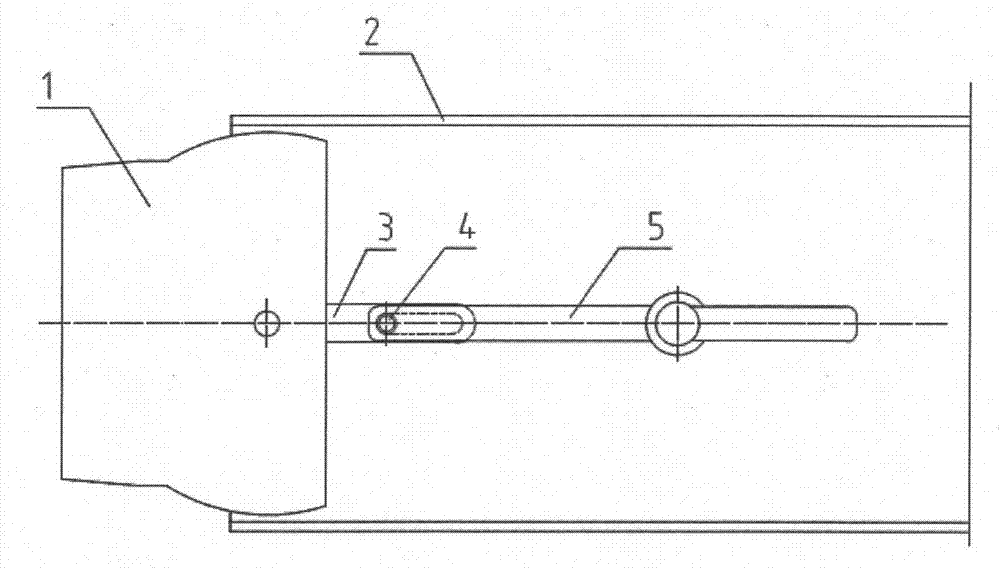

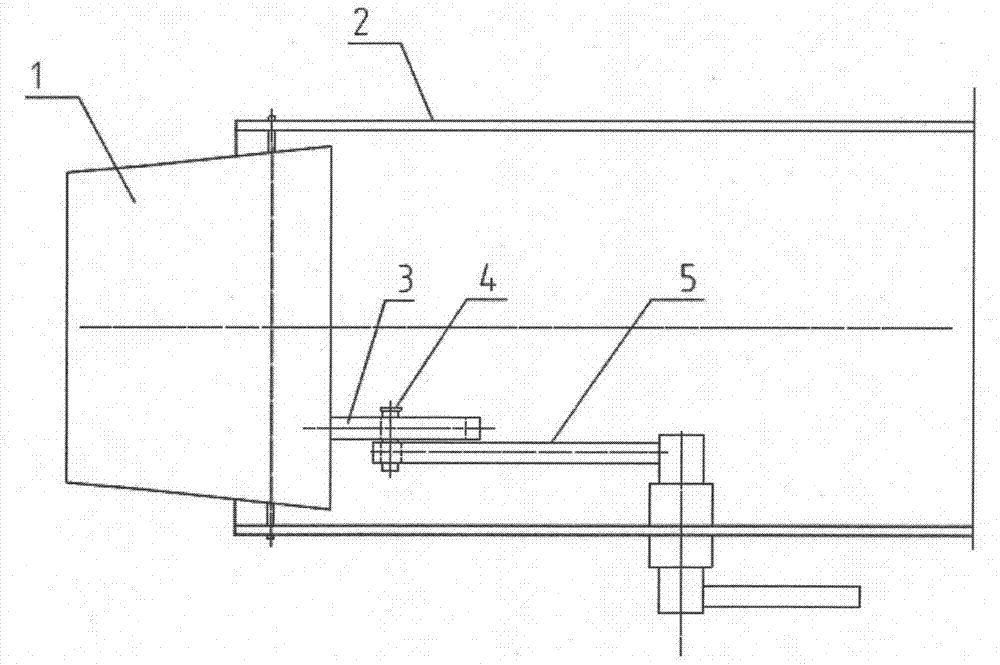

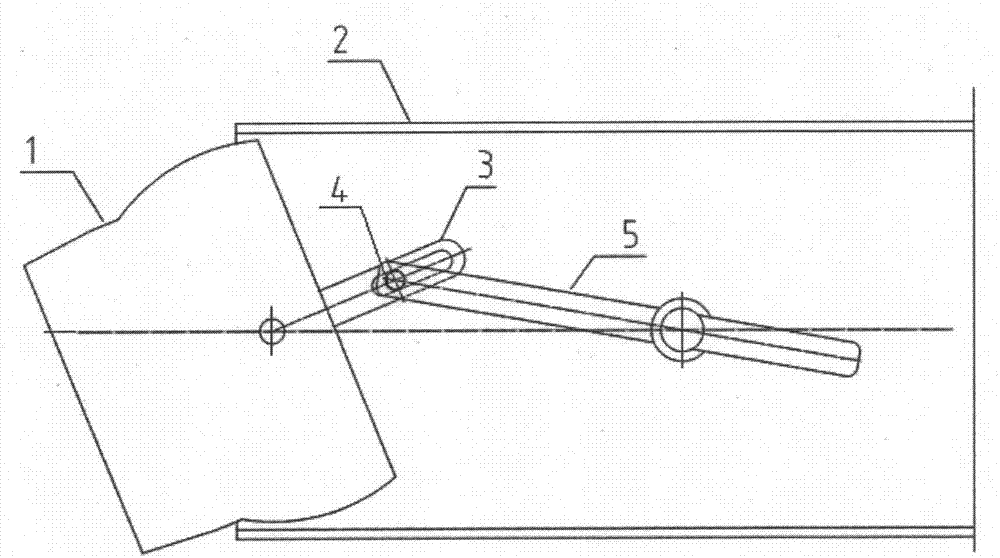

[0033] Figure 1 ~ Figure 3 This is a schematic diagram of the nozzle swing mechanism shown in this embodiment. The nozzle swing mechanism is composed of the nozzle 1, the wind box 2, the swing arm 3, the pin sleeve 4, the main rocker 5 and the like.

[0034] The spout 1 is fixed on the wind box 2 by its own central rotating shaft, and can rotate around the central rotating shaft.

[0035] One end of the swing arm 3 is fixedly connected to the spout 1, and the other end has a waist-shaped hole. The position of the swing arm 3 fixed on the nozzle 1 can be adjusted.

[0036] The main rocker 5 is Z-shaped and is composed of an inner connecting rod, a main connecting rod and an outer connecting rod connected in sequence. The main link is fixed on the bellows 2 and can rotate around the fixed center; the inner link is located inside the bellows 2, one end of the inner link is connected to one end of the main link, and the other end of the inner link has a round hole; the outer link is lo...

Embodiment 2

[0042] Figure 4 ~ Figure 6 This is a schematic diagram of the nozzle swing mechanism shown in this embodiment. The nozzle swing mechanism is composed of the nozzle 1, the wind box 2, the swing arm 3, the pin sleeve 4, the main rocker 5, the transition lever 6, and the like.

[0043] The spout 1 is fixed on the wind box 2 by its own central rotating shaft, and can rotate around the central rotating shaft.

[0044] One end of the swing arm 3 is fixedly connected to the spout 1, and the other end has a waist-shaped hole. The position of the swing arm 3 fixed on the nozzle 1 can be adjusted.

[0045] The main rocker 5 is Z-shaped and is composed of an inner connecting rod, a main connecting rod and an outer connecting rod connected in sequence. The main link is fixed on the bellows 2 and can rotate around the fixed center; the inner link is located inside the bellows 2, one end of the inner link is connected to one end of the main link, and the other end of the inner link has a waist ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com