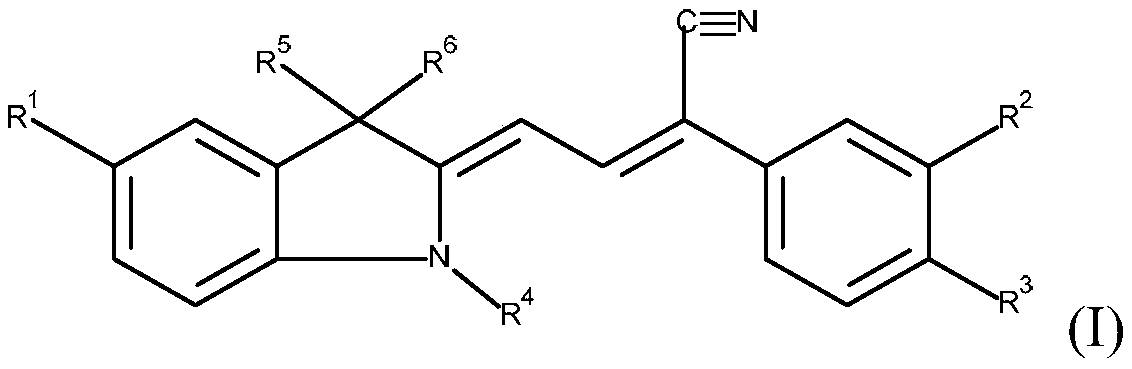

yellow methine dye

A methine dye, methyl technology, applied in the direction of methine/polymethine dyes, organic dyes, organic chemistry, etc., to achieve good heat resistance and light resistance, improve thermal stability, improve the effect of light resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0116] Preparation of compounds according to the invention

[0117]

[0118] where R 1 =-COOCH 3 , R 2 and R 3 = Cl, R 4 =-CH3 and R 5 and R 6 =-CH 3

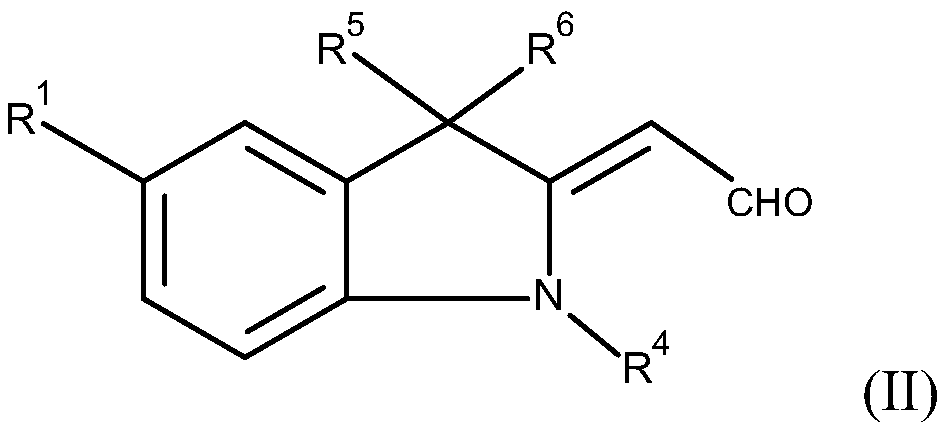

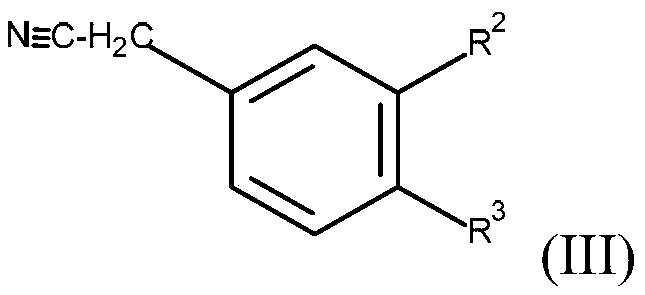

[0119] In a feed of 100 ml of methanol, 25.9 g (=0.1 mol) of aldehydes of formula (II) (wherein R 1 =-COOCH 3 , R 4 =-CH 3 and R 5 and R 6 =-CH 3 ), and 18.6 g (=0.1 mol) of 3,4-dichlorophenylacetonitrile. Subsequently, the pH was adjusted to about 10 with about 1 g of 50% aqueous potassium hydroxide solution, and the reactor contents were heated to 60° C. and then stirred for about 6 hours. The mixture was then cooled to 25° C. and the reaction product was separated on a Nutsche filter. The filter cake was washed with about 50 ml of methanol and about 500 ml of water at a temperature of 90°C. The wet product was dried in a vacuum oven at a temperature of 80° C. and a pressure of 200 mbar.

[0120] Yield: 32.5 g (corresponding to 76% of theory), melting point 241°C

example 2

[0122] Preparation of compounds according to the invention

[0123]

[0124] where R 1 =-COOCH 3 , R 2 = H, R 3 = Cl, R 4 =-CH 3 and R 5 and R 6 =-CH 3

[0125] In a feed of 100 ml of methanol, 25.9 g (=0.1 mol) of aldehydes of formula (II) (where R = -COOCH 3 , R 4 =-CH 3 and R 5 and R 6 =-CH 3 ), and 15.2 g (=0.1 mol) of 4-chlorophenylacetonitrile. Subsequently, the pH was adjusted to about 10 with about 1 g of 50% aqueous potassium hydroxide solution, and the reactor contents were heated to 60° C. and then stirred for about 6 hours. The mixture was then cooled to 25° C. and the reaction product was separated on a Nutsche filter. The filter cake was washed with about 50 ml of methanol and about 500 ml of water (T=90° C.). The wet product was dried in a vacuum oven at a temperature of 80° C. and a pressure of 200 mbar.

[0126] Yield: 31.0 g (corresponding to 79% of theory), melting point 199°C

example 3

[0128] Preparation of compositions according to the invention

[0129]

[0130] where R 1 =-COOCH 3 , R 2 = Cl, R 3 = H, R 4 =-CH 3 and R 5 and R 6 =-CH 3

[0131] In a feed of 100 ml of methanol, 25.9 g (=0.1 mol) of aldehydes of formula (II) (wherein R 1 =-COOCH 3 , R 4 =-CH 3 and R 5 and R 6 =-CH 3 ), and 15.2 g (=0.1 mol) of 3-chlorophenylacetonitrile. Subsequently, the pH was adjusted to about 10 with about 1 g of 50% aqueous potassium hydroxide solution, and the reactor contents were heated to 60° C. and then stirred for about 6 hours. The mixture was then cooled to 25° C. and the reaction product was separated on a Nutsche filter. The filter cake was washed with about 50 ml of methanol and about 500 ml of water (T=90° C.). The wet product was dried in a vacuum oven at a temperature of 80° C. and a pressure of 200 mbar.

[0132] Yield: 29.5 g (corresponding to 75% of theoretical value), melting point 130°C

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com