Low-lactose milk powder and preparation method thereof

A low-lactose, milk powder technology, applied in dairy products, milk preparations, applications, etc., can solve the problems of milk quality risks, unfavorable production equipment turnover, increase production costs, etc., to ensure quality and microbial indicators, shorten hydrolysis time, effect of adding value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

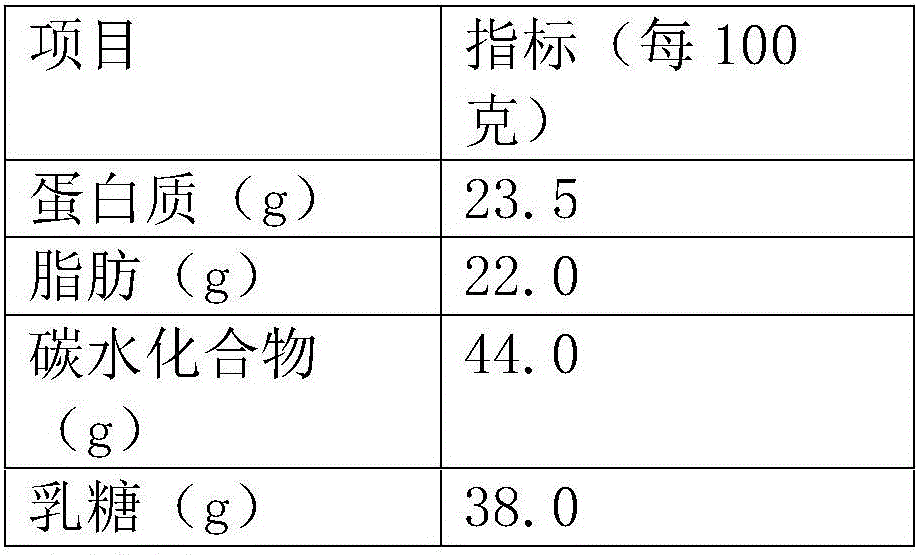

Embodiment 1

[0016] (1) Acceptance of raw milk: refer to the physical and chemical indicators and microbial indicators of the national standard GB19301 to check and accept raw milk (physical and chemical indicators: fat ≥ 3.1%, protein ≥ 2.8%, acidity: 12-18 。 T; microbial index: the total number of colonies ≤ 2 million / cfu);

[0017] (2) Separation and cleaning of milk: use 80 and 200 mesh filters to filter the raw milk twice, remove impurities through the separator, and standardize the milk;

[0018] (3) Pre-sterilization: Pre-sterilize the standardized milk (80°C, 15S) and store it below 6°C;

[0019] (4) Initial batching: heat up the milk in (3), add whole milk powder, polydextrose and other raw materials for initial batching;

[0020] (5) Secondary ingredients: check the physical and chemical indicators of the completed primary ingredients, and adjust again through water replenishment and constant volume operation to reduce the material indicators to the required physical and chemica...

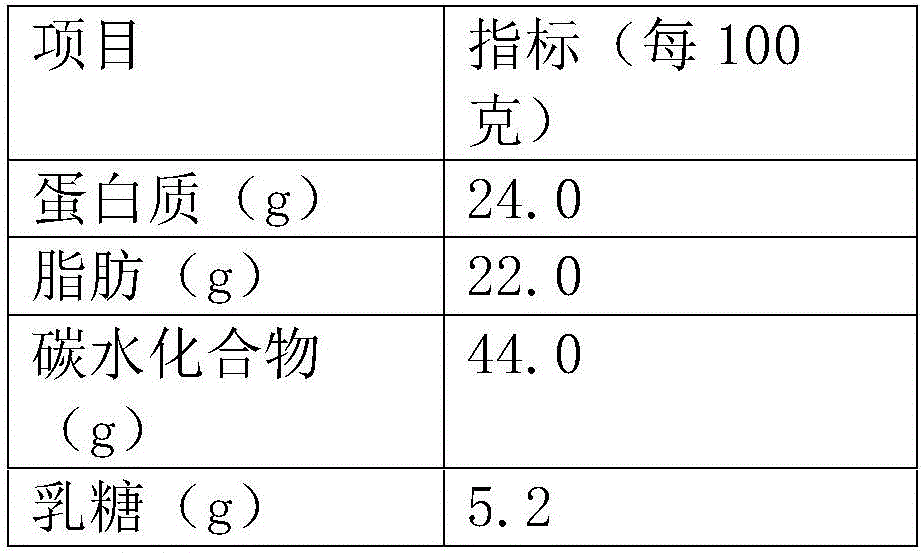

Embodiment 2

[0033] (1) Acceptance of raw milk: refer to the physical and chemical indicators and microbial indicators of the national standard GB19301 to check and accept raw milk (physical and chemical indicators: fat ≥ 3.1%, protein ≥ 2.8%, acidity: 12-18 。 T; microbial index: the total number of colonies ≤ 2 million / cfu);

[0034] (2) Separation and cleaning of milk: use 80 and 200 mesh filters to filter the raw milk twice, remove impurities through the separator, and standardize the milk;

[0035] (3) Pre-sterilization: Pre-sterilize the standardized milk (80°C, 15S) and store it below 6°C;

[0036] (4) Initial batching: heat up the milk in (3), add whole milk powder, polydextrose and other raw materials for initial batching;

[0037] (5) Secondary ingredients: check the physical and chemical indicators of the completed primary ingredients, and adjust again through water replenishment and constant volume operation to reduce the material indicators to the required physical and chemica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com