Flue gas purifying absorbing tower and processing method thereof

A flue gas purification and absorption tower technology, applied in gas treatment, chemical instruments and methods, separation methods, etc., can solve problems such as the inability to guarantee the space utilization rate of the absorption tower body.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

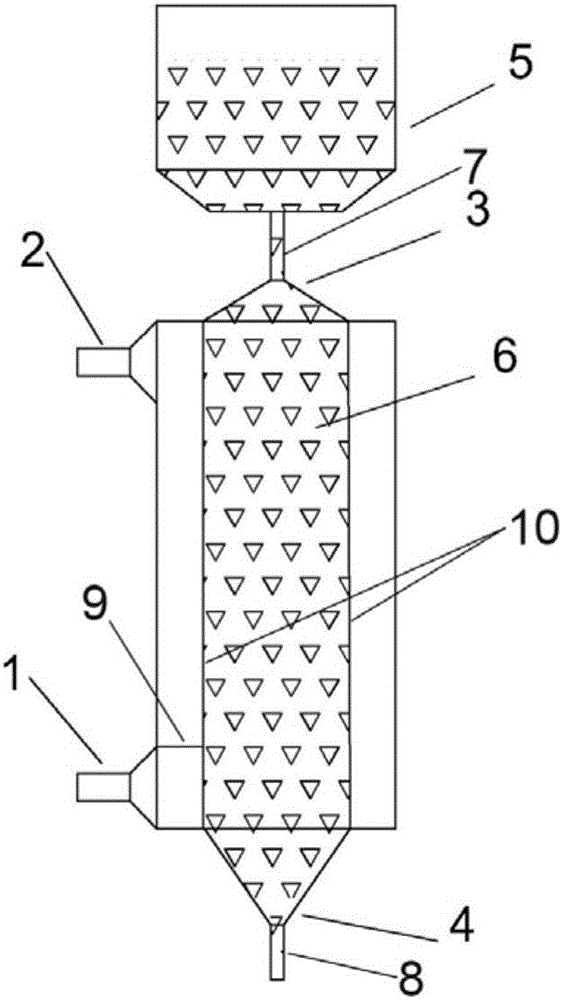

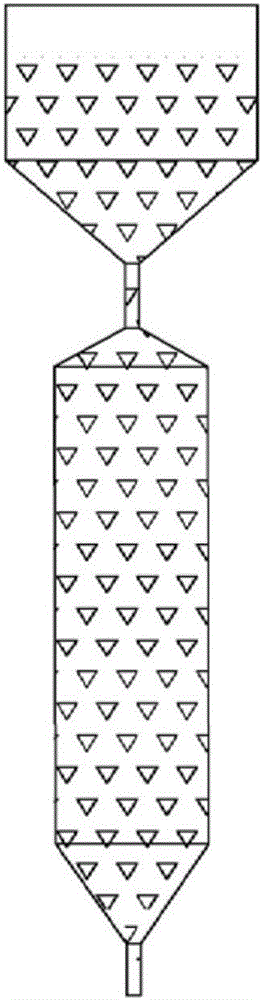

[0077] This embodiment provides a flue gas purification absorption tower, the adsorbent used in the flue gas purification absorption tower is activated carbon, and the structure of the absorption tower is as follows figure 1 and figure 2 As shown, the size of the tower body is 2m in length, 4m in width, and 10m in height, and the flue gas volume that can be treated is 8000Nm 3 / h, a layer of adsorbent layer 6 with a thickness of 2m is arranged in the middle of the tower body, porous plates 10 are arranged on both sides of the adsorbent layer, and the flue gas channels on both sides of the adsorbent layer are each 1m wide. The lower part of the tower body is provided with an air inlet 1, on one side of the air inlet 1, a baffle 9 is arranged horizontally in the space above the air inlet 1 between the tower body and the adsorbent layer 6, and the upper part of the tower body is arranged on the same side as the air inlet 1 Gas outlet 2, the top of the tower body is provided wit...

Embodiment 2

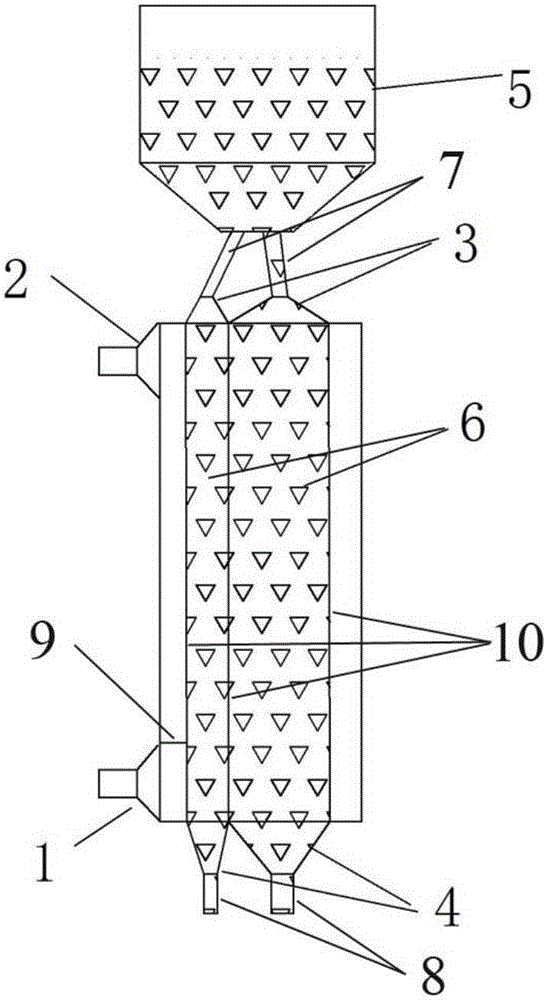

[0084]This embodiment provides a flue gas purification absorption tower, the adsorbent used in the flue gas purification absorption tower is activated carbon, and the structure of the absorption tower is as follows image 3 and Figure 4 As shown, the size of the tower body is 8m in length, 4m in width, and 16m in height, and the flue gas volume that can be treated is 50000Nm 3 / h, the total thickness of the adsorbent layer 6 in the middle of the tower body is 2m. In order to better realize the desulfurization and denitrification process, the adsorbent layer 6 is divided into two layers, and its thickness is respectively 50cm and 150cm. It is a perforated plate 10, and the layers are also separated by the perforated plate 10. The perforated plate 10 in this embodiment is a steel plate. The lower part of the tower body is provided with an air inlet 1, on one side of the air inlet 1, a baffle 9 is arranged horizontally in the space above the air inlet 1 between the tower body a...

Embodiment 3

[0092] This embodiment provides a flue gas purification absorption tower, whose specific structure and treatment method refer to Example 1, the difference is that the adsorbent used in the flue gas purification absorption tower is activated coke, and the thickness of the adsorbent layer 6 is 1m. The angle of inclination of the feeding pipeline 7 is 80°.

[0093] The material inlet and outlet structure of the tower body in this embodiment enables the adsorbent to move smoothly from the top of the tower body to the bottom of the tower body, the physical wear of the adsorbent is less than 0.5%, the space utilization rate of the tower body is high, and the adsorption and removal can be carried out efficiently. used to treat SO 2 3 ,NO x 3 , the flow rate is 4000Nm 3 / h flue gas, its flue gas desulfurization rate is above 98%, denitrification rate is above 80%, and it can remove more than 50% of dust and more than 80% of heavy metals. method of contamination.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com