Overall-prefabricated light steel keel combined wall-column synergistic shear resistant member and assembly method

A light steel keel and composite wall technology, applied in the direction of building components, walls, building structures, etc., can solve the problems of low rigidity of square steel tube concrete columns, failure to achieve the ideal failure mode, and difficulty in avoiding buckling damage, etc., to improve the resistance Shear performance and vertical bearing capacity, ensuring the overall lateral resistance and vertical stability, and enhancing the overall lateral resistance and vertical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further explained below in conjunction with the drawings.

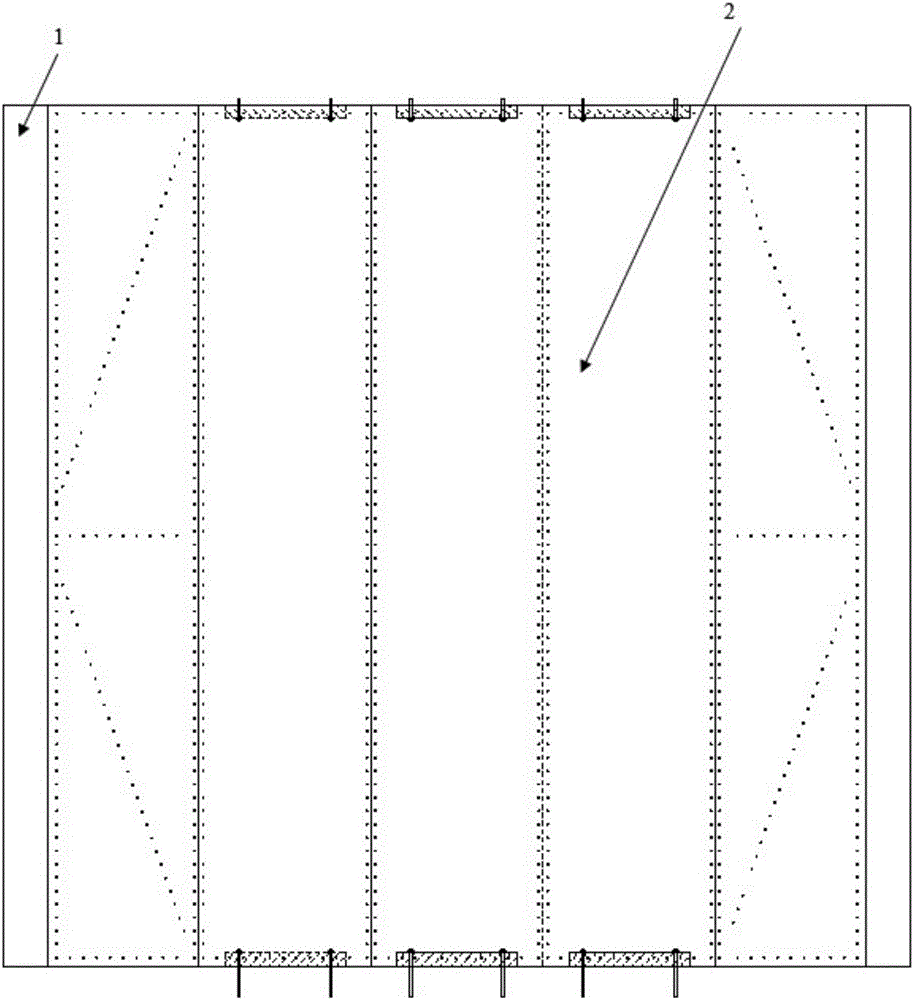

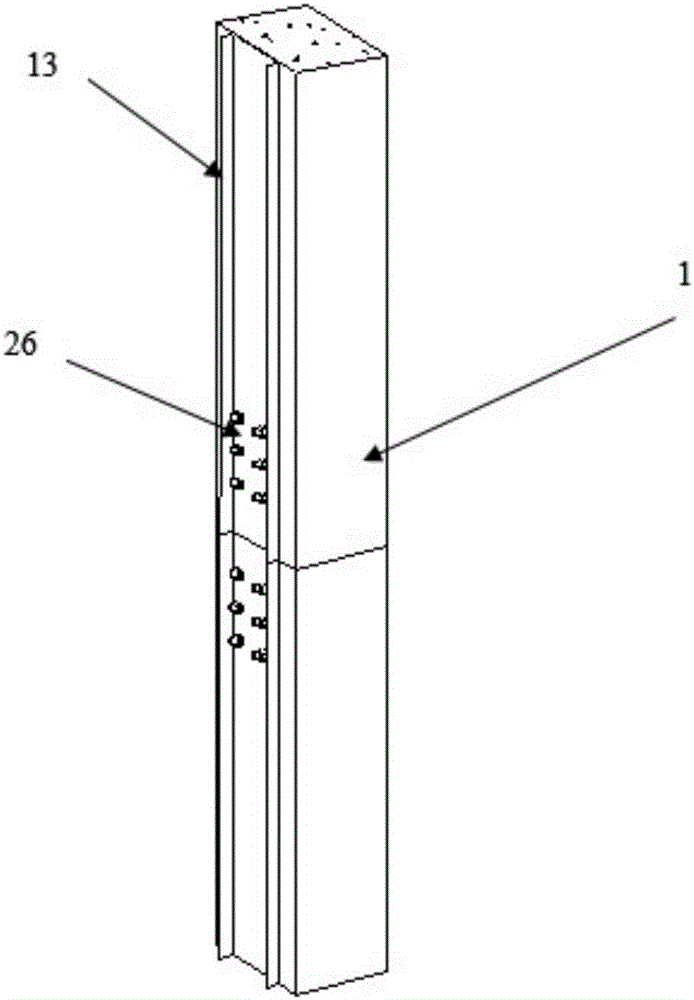

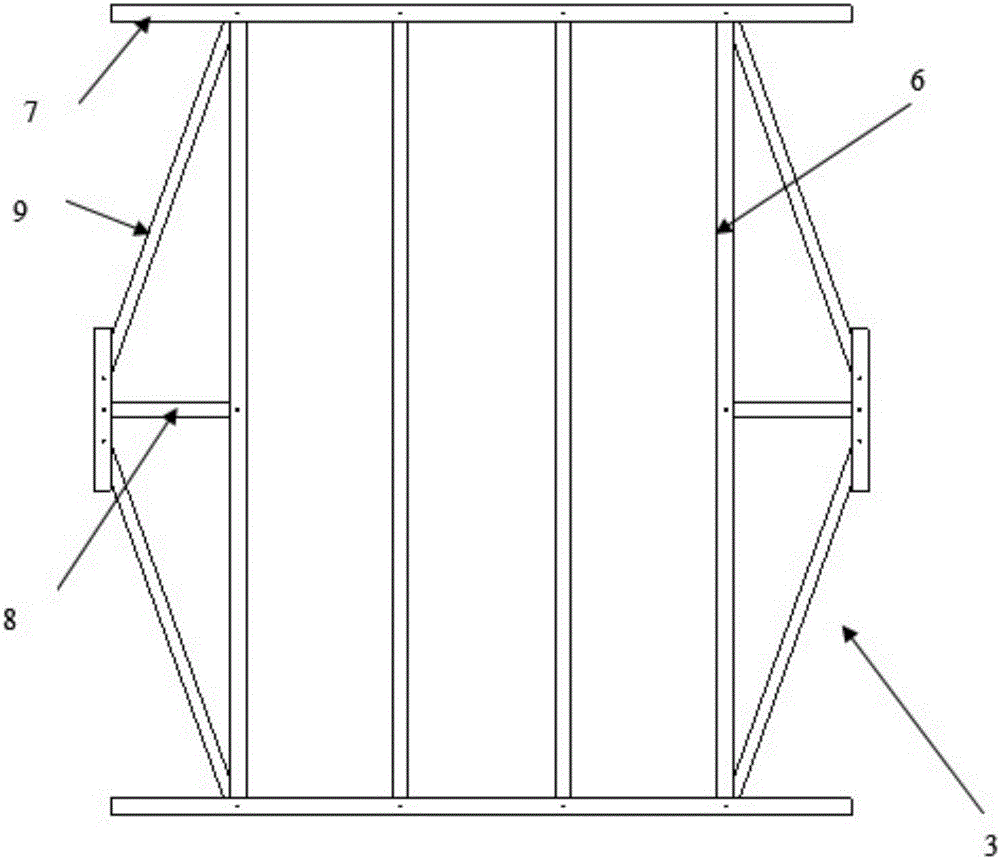

[0037] Such as figure 1 As shown Figure 1-Figure 6 As shown, a fully prefabricated lightweight steel keel composite wall-column collaborative shear-resistant component of the present invention includes a concrete-filled steel tube column 1 and an internal wall element 2, wherein the internal wall element 2 includes a light steel frame 3, a cross tie rod 4 and a wall panel 5; Light steel framework 3 is formed by C-shaped light steel keel column 6, U-shaped light steel keel guide 7, stiffening cross brace 8 and stiffening diagonal brace 9 connected by self-tapping screws 10, cross tie rod 4 passes through the C-shaped light steel keel The reserved holes 11 of the column 6 are arranged inside the light steel frame 3, and the wall panels 5 are arranged on both sides of the light steel frame 3 and connected by self-tapping screws 10 to form an internal wall element 2; two steel tube concre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com