Degreased highland barley product and production method

A production method, highland barley technology, applied in the field of grain deep processing, can solve the problems of high oil content in highland barley, unfavorable pursuit of healthy eating habits, etc., and achieve the effects of simple operation, prevention of cardiovascular and cerebrovascular diseases, and lowering cholesterol

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

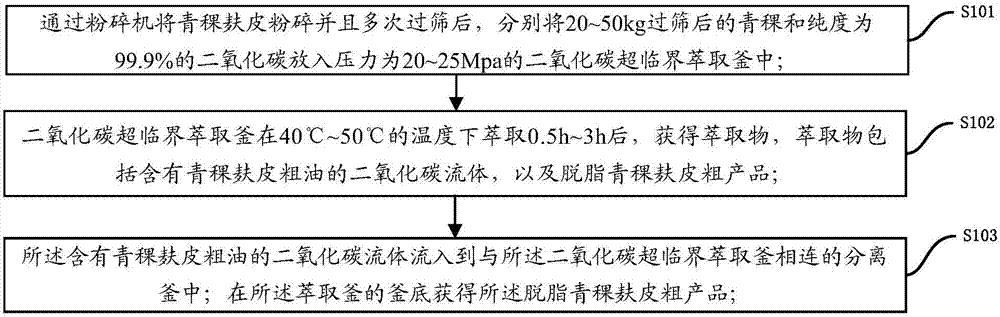

[0020] figure 1 It is a schematic flowchart of a production method of a defatted highland barley product provided in Example 1 of the present invention. like figure 1 As shown, the method includes steps S101-S103:

[0021] In step S101, the highland barley bran is pulverized by a pulverizer and passed through a 400-mesh sieve several times to obtain 20-50 kg of highland barley bran; respectively put 20-50 kg of highland barley bran and carbon dioxide with a purity of 99.9% into the pressure of 20-25 Mpa carbon dioxide supercritical extraction kettle.

[0022] Preferably, the pressure of the extraction tank is 20-25Mpa.

[0023] Step S102, extracting in a carbon dioxide supercritical extraction kettle at a temperature of 40° C. to 50° C. for 0.5 h to 3 h to obtain an extract, which includes a carbon dioxide fluid containing crude oil of highland barley bran and defatted highland barley bran.

[0024] In step S103, the carbon dioxide fluid containing crude oil of highland ba...

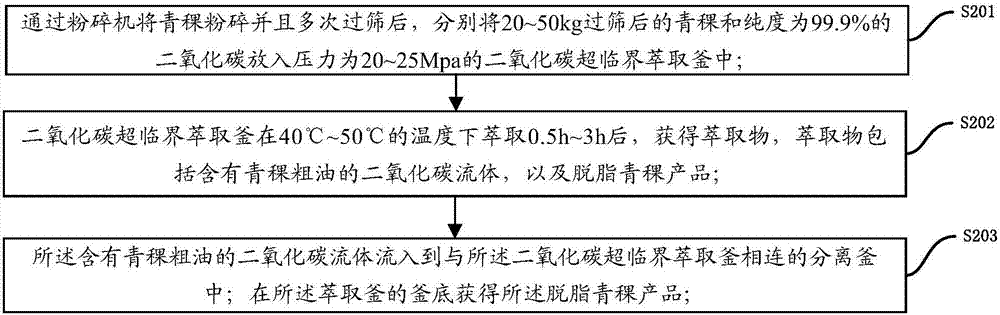

Embodiment 2

[0031] After the highland barley bran is pulverized by a pulverizer and 3 passes through a 400 mesh sieve, 30kg of sieved highland barley bran and carbon dioxide with a purity of 99.9% are put into a carbon dioxide supercritical extraction kettle with a pressure of 25Mpa; the carbon dioxide flow rate is 18kg / h. The carbon dioxide supercritical extraction kettle is extracted at a temperature of 50° C. for 3 hours to obtain the extract, which includes the carbon dioxide fluid containing the crude oil of highland barley bran and the defatted highland barley bran; the carbon dioxide fluid containing the crude oil of highland barley bran flows into the In a separation tank connected to a carbon dioxide supercritical extraction tank; the defatted highland barley bran is obtained at the bottom of the extraction tank.

[0032] Preferably, after obtaining the defatted highland barley bran, before detecting the defatted highland barley bran, the defatted highland barley bran is treated...

Embodiment 3

[0036] After the highland barley bran is pulverized by a pulverizer and passed through a 400 mesh sieve for 4 times, the highland barley bran after sieving and the carbon dioxide with a purity of 99.9% are put into a pressure of 20Mpa respectively in a carbon dioxide supercritical extraction kettle of 20Mpa; It is 25kg / h. The carbon dioxide supercritical extraction kettle is extracted at a temperature of 40°C for 2 hours to obtain the extract, which includes a carbon dioxide fluid containing the crude oil of highland barley bran and defatted highland barley bran; the carbon dioxide fluid containing the crude oil of highland barley bran flows into the In a separation tank connected to a carbon dioxide supercritical extraction tank; the defatted highland barley bran is obtained at the bottom of the extraction tank.

[0037] Preferably, before detecting the defatted highland barley bran, the defatted highland barley bran is treated in a boiling water bath at 89° C. for 2 hours. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com