Preparation method for low-refractive-index high-transparency silicon dioxide

A silicon dioxide and refractive index technology, applied in the direction of silicon dioxide, silicon oxide, cosmetic preparations, etc., can solve the problems of low transparency and achieve the effects of simple preparation method, reduced dosage and stable process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

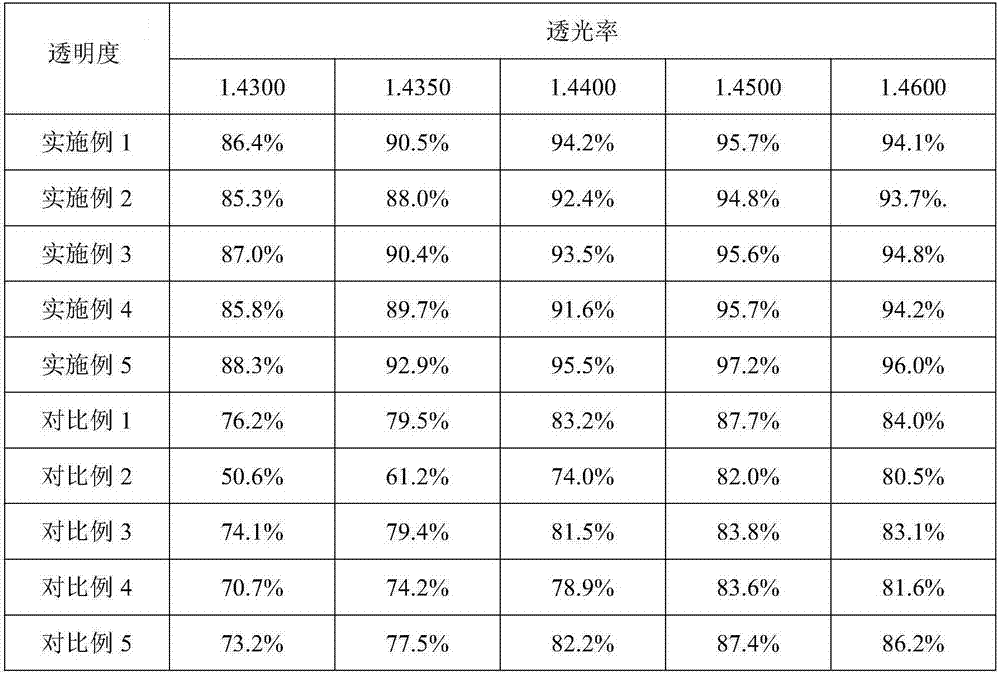

Examples

Embodiment 1

[0024] Embodiment 1, the preparation method of low refractive index and high transparency type silica of the present invention

[0025] S1. Prepare a water glass solution with a concentration of 2.0M, and keep it at 30° C. for 12 hours to obtain water glass sol seed crystals;

[0026] S2. Take water glass sol seed crystals, add water to dilute, and prepare a water glass bottom solution with a concentration of 0.5M;

[0027] S3, add water glass bottom liquid 3m in reaction kettle 3 and a concentration of 5.0% sodium sulfate solution 10m 3 , stir evenly and heat to 55°C;

[0028] S4, drop water glass sol seed crystal 10m at the same time 3 and a sulfuric acid solution with a concentration of 5.0M, and the pH of the control process is 7-8. After the water glass sol seed crystals are added dropwise, continue to add the sulfuric acid solution until the final pH is 5.0-5.5, and stir for 30 minutes;

[0029] S5. Stop stirring, keep at 55° C., age for 1 h, press filter and wash th...

Embodiment 2

[0030] Example 2, the preparation method of low refractive index and high transparency silica of the present invention

[0031] S1. Prepare a water glass solution with a concentration of 3.0M, and keep it at 50° C. for 8 hours to obtain water glass sol seed crystals;

[0032] S2. Take water glass sol seed crystals, add water to dilute, and prepare a water glass bottom solution with a concentration of 1.0M;

[0033] S3, add water glass bottom liquid 5m in reaction kettle 3 and a concentration of 10.0% sodium sulfate solution 15m 3 , stir evenly and heat to 75°C;

[0034] S4, drop water glass sol seed crystal 15m at the same time 3 and a sulfuric acid solution with a concentration of 8.0M, and the pH of the control process is 8-9. After the water glass sol seed crystals are added dropwise, continue to add the sulfuric acid solution until the final pH is 5.5-6.0, and stir for 50 minutes;

[0035] S5. Stop stirring, keep at 75° C., age for 2 hours, press filter and wash the fo...

Embodiment 3

[0036] Example 3, the preparation method of low refractive index and high transparency silica of the present invention

[0037] S1. Prepare a water glass solution with a concentration of 3.0M, and keep it at 40° C. for 10 hours to obtain water glass sol seed crystals;

[0038] S2. Take water glass sol seed crystals, add water to dilute, and prepare a water glass bottom solution with a concentration of 0.5M;

[0039] S3, add water glass bottom liquid 4m in reactor 3 and 8.0% sodium sulfate solution 12m 3 , stir evenly and heat to 65°C;

[0040] S4, drop water glass sol seed crystal 13m at the same time 3 and a sulfuric acid solution with a concentration of 6.0M, and the pH of the control process is 7-8. After the water glass sol seed crystals are added dropwise, continue to add the sulfuric acid solution until the final pH is 5.4-5.8, and stir for 40 minutes;

[0041] S5. Stop stirring, keep at 65° C., age for 2 hours, press filter and wash the formed silica precipitate, dr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com