Novel method for improving strength and thermal shock property of opacified glass product

A technology of opacity glass and thermal shock, which is applied in glass tempering, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of low mechanical strength, complicated process, and poor thermal shock performance of tableware, and achieve suitable promotion and technological process Simple, good thermal shock resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

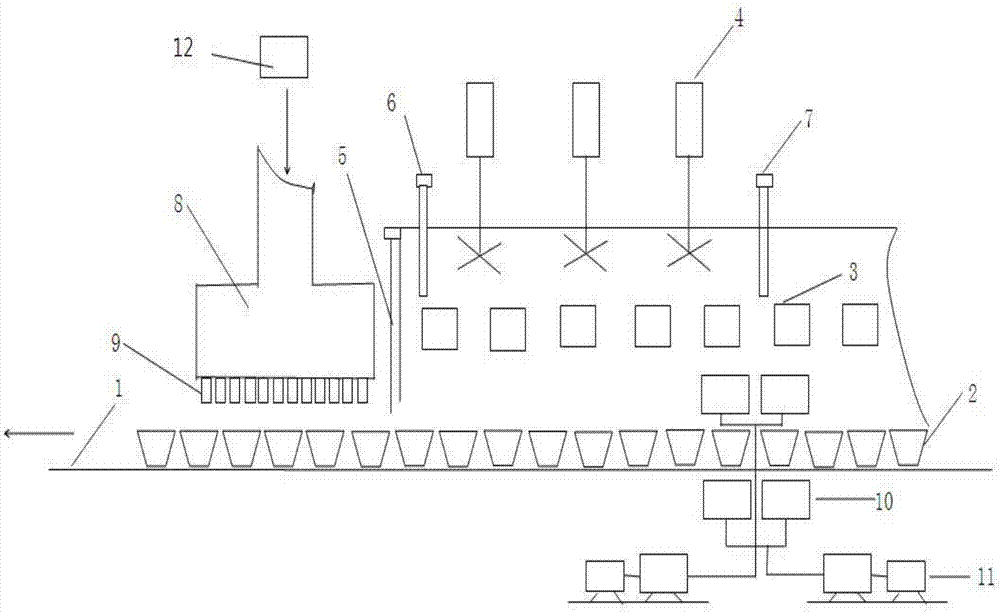

[0025] Please refer to figure 1 , a new method of improving the strength and thermal shock resistance of opaque glass products, that is, by implementing chemical tempering (ion replacement method) during the physical tempering (air-cooling quenching) process of opaque glass products to improve their strength and thermal shock resistance; Include the following steps:

[0026] (1) Screening of ion exchange materials: select K 3 PO 4 、KNO 3 , KCL, K 2 SO 4 Any one of the materials; according to the comprehensive consideration of the effect, safety, environmental protection, cost and other factors, after repeated tests, KCL is finally selected as the ion exchange raw material.

[0027] (2) The definition of the initial temperature during ion replacement (chemical toughening): the initial temperature is 400°C, the cut-off temperature is 640°C; the chemical toughening time is between 6min-8min; the determination of the initial test temperature of spraying starts from the temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com