Anti-crack enhanced large-volume super-length structural concrete and preparation method thereof

A concrete and super-long technology, which is applied in the field of crack-resistant reinforced large-volume super-long structural concrete and its preparation, can solve problems such as strengthening mineral powder and fly ash hydration, large-volume super-long structural concrete cracks, etc., to achieve increased The workability of cement, the effect of improving compactness and impermeability, and reducing the amount of cement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

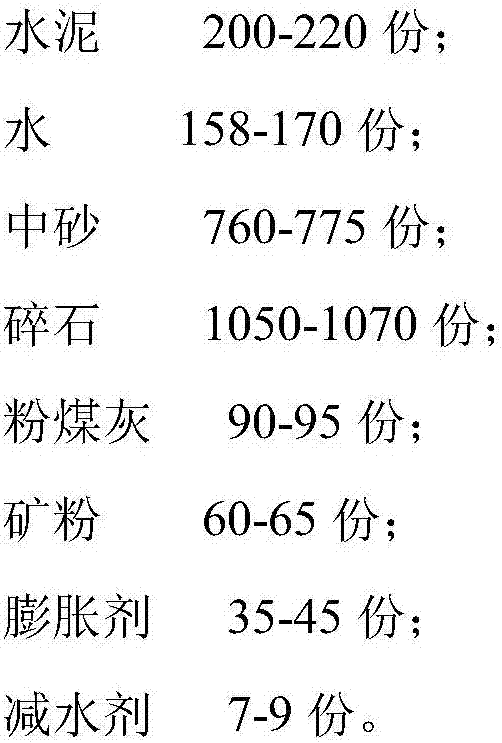

[0044] Components and proportioning ratios in each embodiment are shown in Table 2.

[0045] Table 2 Components and proportions of anti-cracking reinforced large-volume super-long structure concrete in each embodiment

[0046]

[0047] Among them, according to the "GB / T14685-2011" to detect the nature of the crushed stone, the apparent density of the crushed stone is 2820kg / m 3,The continuous gradation of crushed stones has a loose packing porosity of 43%; the alkali-aggregate reaction in the concrete is tested, and the expansion rate is 0.04% in 14 days, and the loose packing density is 1600kg / m 3 .

[0048] The preparation method of the anti-cracking reinforced large-volume super-long structure concrete of the above embodiment one to embodiment seven is as follows:

[0049] (1) According to the ratio in Table 2, the water reducer and water are pre-mixed and stirred to form an admixture solution, and the stirring speed is 800r / min;

[0050] (2) Make the machine-made san...

Embodiment 6

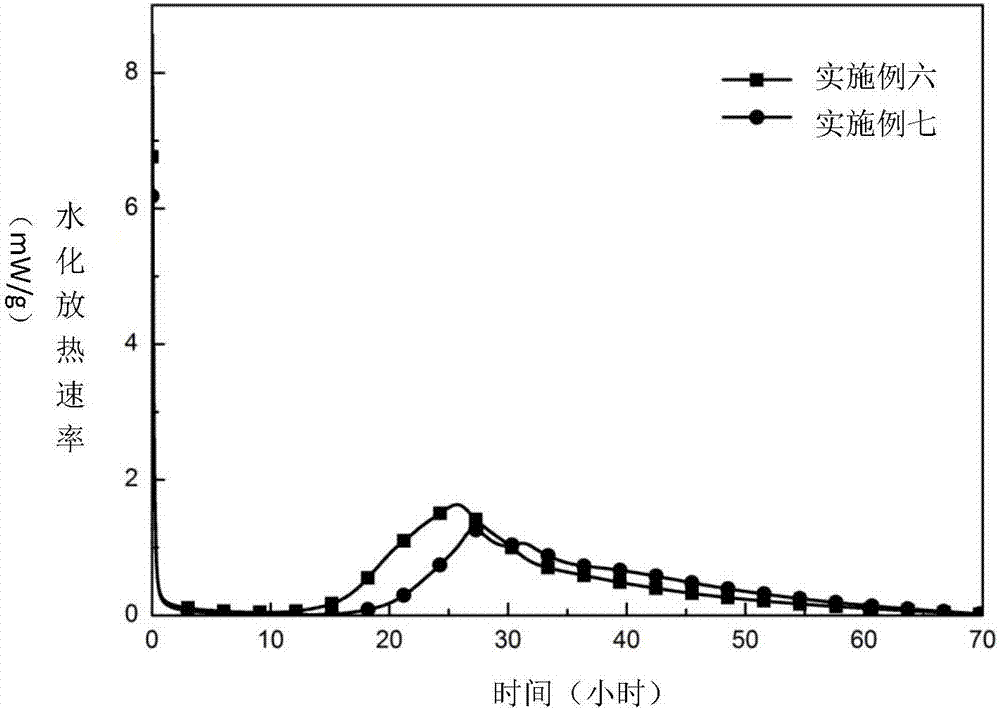

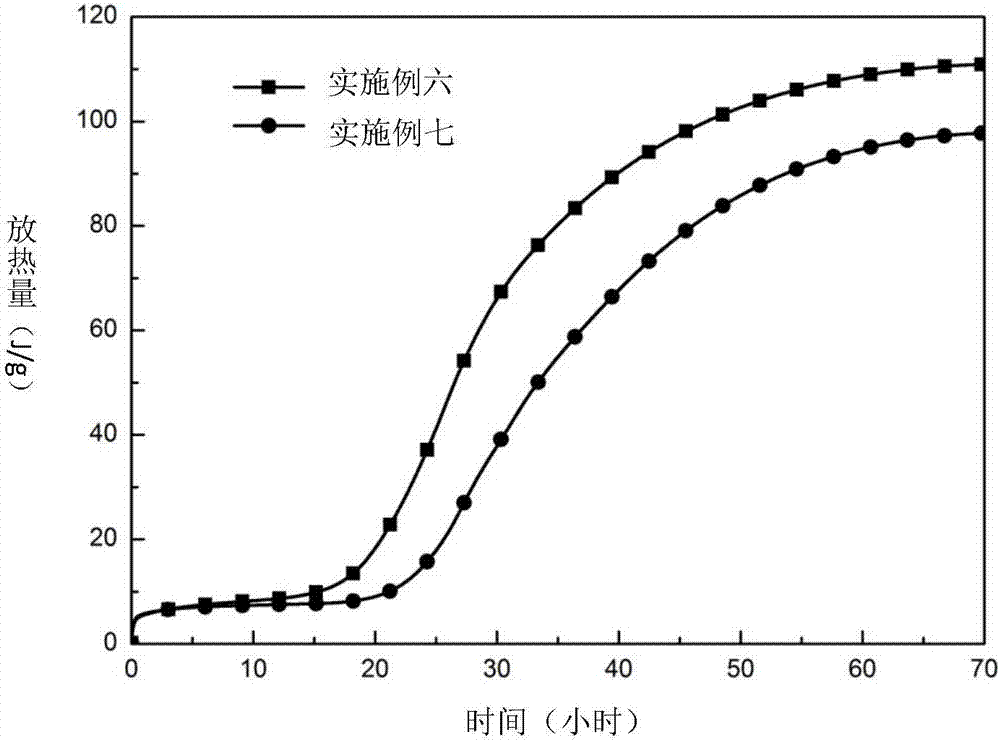

[0067] The bulk density of the concrete that embodiment six and embodiment seven make is 2400kg / m 3 , sand rate is 0.38. Cement, fly ash, slag, water reducer and water in test embodiment six and embodiment seven are mixed to form the heat release of bulky cementitious material when the test ends (72h), and the temperature rise value of prediction concrete is as table 4.

[0068] The heat release and temperature rise value of the concrete that table 4 embodiment six and embodiment seven make

[0069]

[0070]

[0071] It can be seen from the above results that when the amount of mineral admixtures (fly ash and mineral powder) replacing cement increases, the temperature rise of concrete is small.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent density | aaaaa | aaaaa |

| Slump | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com