A kind of sealing agent for HVOF to prepare Fe-based amorphous coating

An amorphous coating and sealing agent technology, applied in coatings, anti-corrosion coatings, fire-retardant coatings, etc., to achieve the effect of solving porosity and crystallization, strong insulation and adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

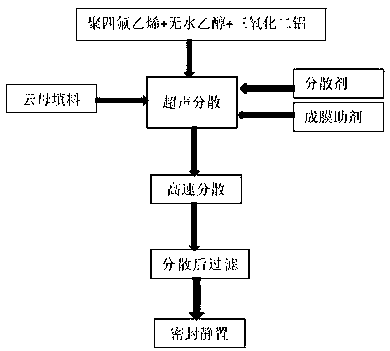

[0021] The specific embodiment of the present invention is as figure 1 shown.

[0022] This embodiment is achieved by adding 25 parts of nanometer Al 2 o 3 , Ultrasonic dispersion is uniform, add 10 parts of mica filler, 5 parts of dispersant (sodium polyacrylate) and 5 parts of film-forming aid, and then add an appropriate amount of anhydrous ethanol solvent to adjust the viscosity, and then put them together in a high-speed disperser, and disperse evenly After filtering, sealing and standing still, the required sealing agent is prepared.

[0023] Before sealing, the coating sample is pretreated and ultrasonically cleaned to ensure that the surface of the coating is clean and free of stains. Then, an appropriate amount of curing agent is added to the sealing agent, and the coating to be sealed is immersed in the sealing agent. After dipping for 20 minutes, make the sealing agent fully penetrate into the pores of the coating, then place the sample at room temperature to dry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com