High-frequency synchronous rectification switching power supply

A synchronous rectification switch and power supply technology, which is applied in the modification of electrical components and power electronics, and the conversion of AC power input to DC power output, etc., can solve the problems of poor heat dissipation, achieve local high-temperature areas, reduce overall volume, and improve The effect of cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

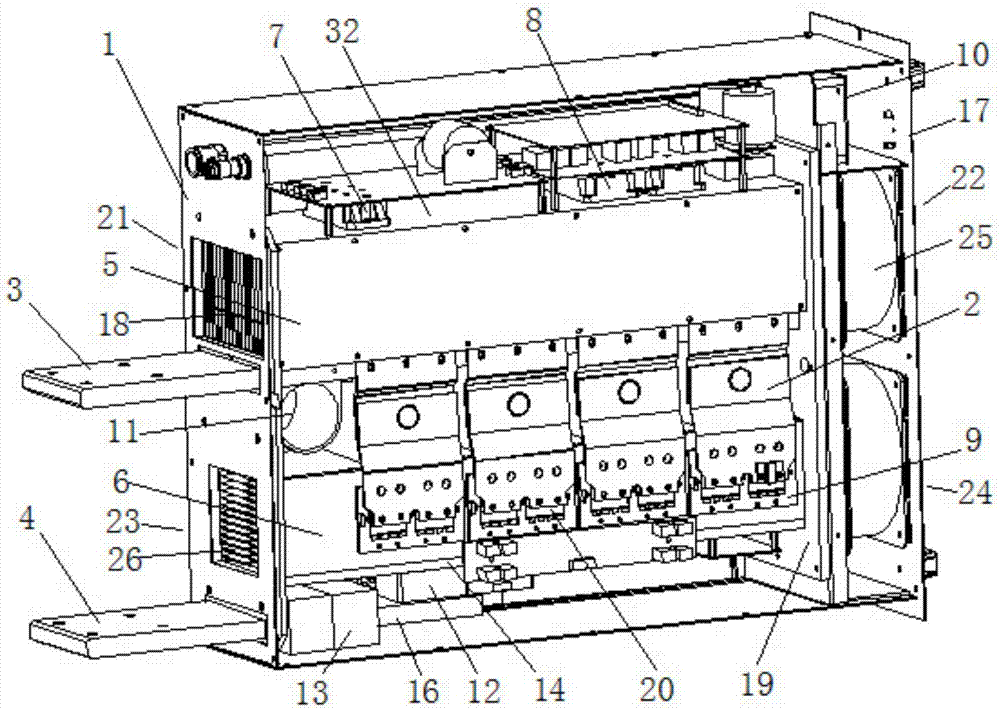

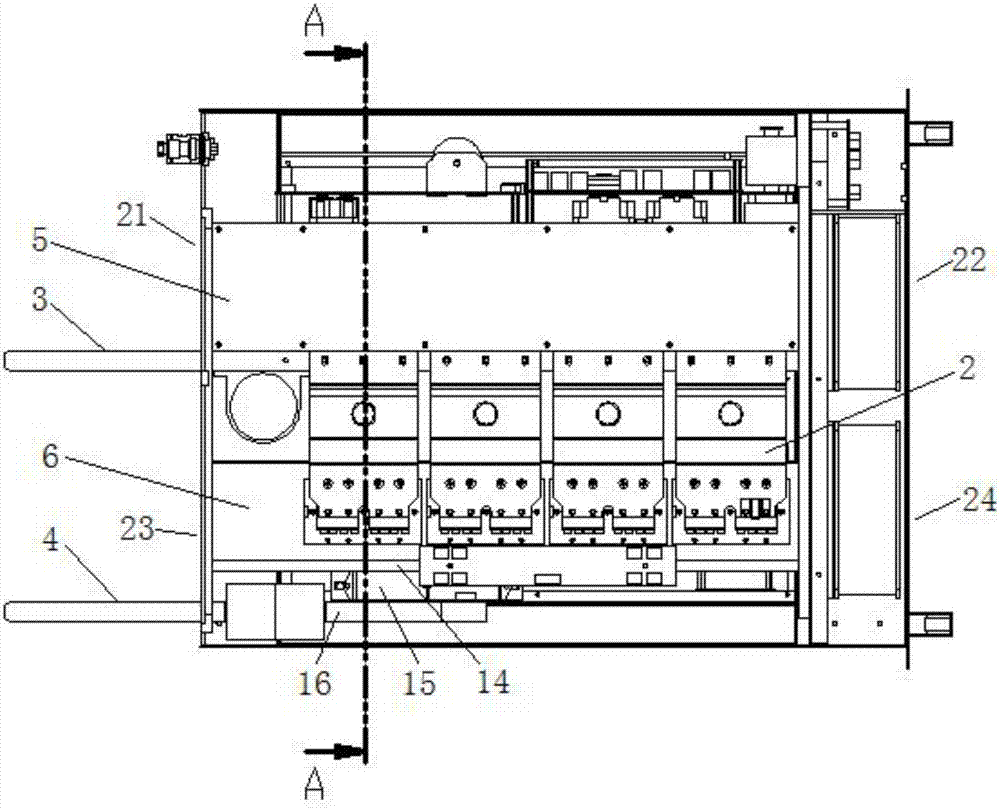

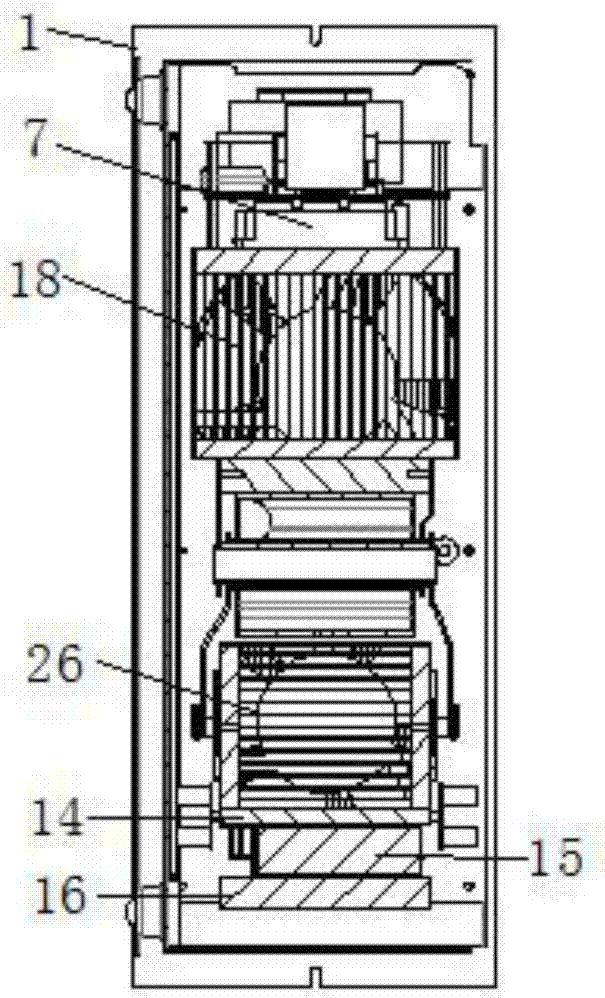

[0077] Such as figure 1 , figure 2 , image 3 As shown, the high-frequency synchronous rectification switching power supply includes: a chassis 1, a transformer 2, a first plate 3, a second plate 4, a first heat dissipation channel 5, a second heat dissipation channel 6, a first rectifier module 7, a chopper Module 8, second rectification module 9 and fan 25.

[0078] Insulation plates 19 are provided on the inner walls at both ends of the case 1; a shielding box 17 is provided inside the case 1, and the shielding box 17 is used to accommodate the control trigger circuit 10 of the high-frequency synchronous rectification switching power supply.

[0079] Such as Figure 5 , Figure 7 As shown, the transformer 2 has a plurality of transformers, which are installed side by side between the first heat dissipation passage 5 and the second heat dissipation passage 6 along the extending direction of the first heat dissipation passage 5 and the second heat dissipation passage 6. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com