Pressure swing adsorption device and control method thereof

A technology of pressure swing adsorption and control method, which is applied in the direction of separation method, chemical instrument and method, gas treatment, etc. It can solve the problems of uneven flow rate of raw gas products and reduced investment, so as to save equipment investment, avoid bias flow, The effect of low sealing performance requirement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following non-limiting examples illustrate the invention.

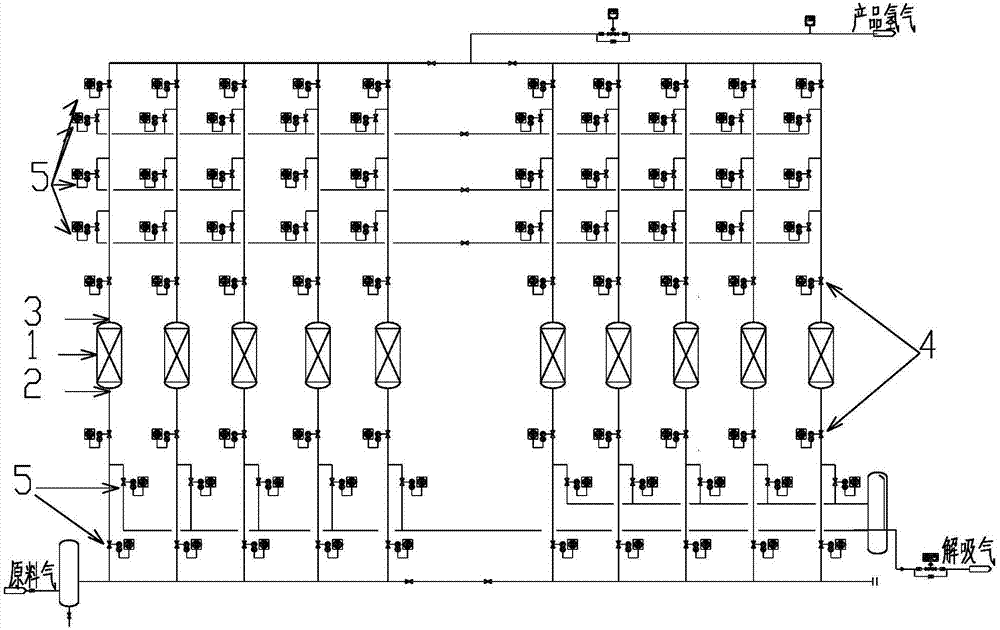

[0031] A pressure swing adsorption device, a program control regulating valve 4 is respectively connected to the main pipe at the inlet and outlet ends of the adsorber (such as the adsorption tower 1 shown in this embodiment) of the pressure swing adsorption device, and after the program control regulating valve 4 , and then connected with other corresponding program-controlled valves 5 through pipelines.

[0032] As an example, such as figure 1 As shown, the pressure swing adsorption device is composed of 4 or more adsorption towers 1 and a program-controlled valve 5 to form a continuous operation system. On the adsorption tower inlet 2 and adsorption tower outlet 3 of each adsorption tower 1 of the pressure swing adsorption device A program control regulating valve 4 is respectively connected, and after the program control regulating valve 4 is connected with other corresponding program control valves 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com