Method for preparing sintered brick by utilizing water base well drilling cuttings

A technology of sintered bricks and well drilling, which is applied in the field of oil and gas field drilling cuttings waste treatment, to achieve the effect of realizing solid waste recycling, simplifying the process, and reducing waste of water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

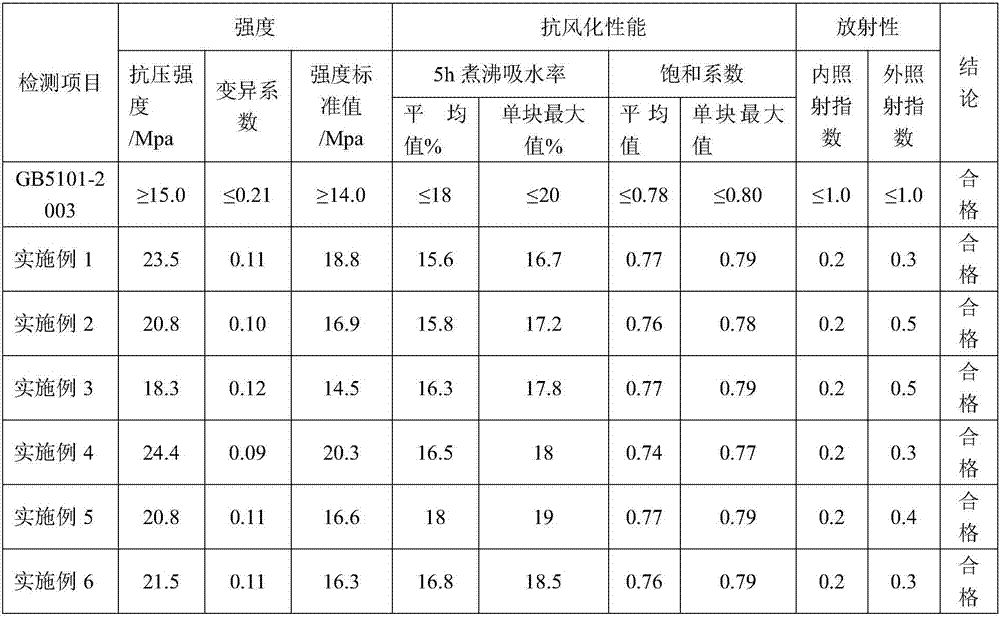

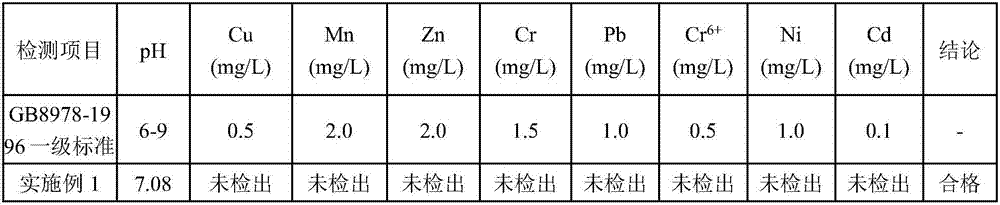

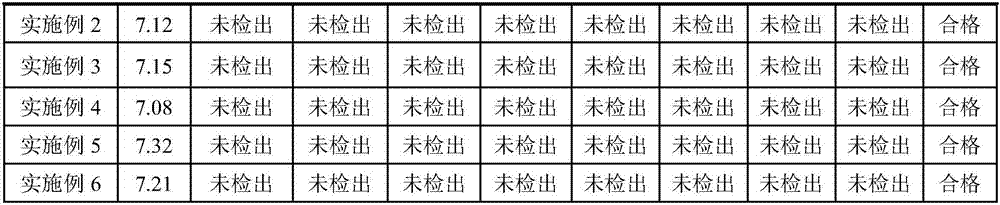

Examples

Embodiment 1

[0037] A method for preparing sintered bricks from water-based drilling cuttings, comprising the steps of:

[0038] (1) Water-based drilling cuttings are automatically added into the sinking continuous reactor, and 0.5% by mass modifier is added to the reactor for full reaction to obtain reformed solid waste; (2) the reformed The solid waste is transported to the brick factory, stacked and dried naturally for 3 days in the raw material area of the brick factory, and then the modified solid waste is mixed with internal combustion materials and shale soil at a weight ratio of 3:1:3, crushed, and sieved. Obtain the mixture; (3) transfer the mixture to the brick mixing mixing system, and then add 10% by mass of tap water, drilling waste water, fracturing flowback water and gas production and oil production waste water, or a mixture of at least two, Stir, shape, and make adobe; (4) Dry the adobe for 48 hours and send it to a brick kiln, sinter at 1100°C for 10 hours, then cool an...

Embodiment 2

[0040] A method for preparing sintered bricks from water-based drilling cuttings, comprising the steps of:

[0041] (1) Water-based drilling cuttings are automatically added to the sinking continuous reactor, and 2.0% by mass of a modifier is added to the reactor for full reaction to obtain reformed solid waste; (2) the reformed The solid waste is transported to the brick factory, stacked and dried naturally for 7 days in the raw material area of the brick factory, and then the modified solid waste is mixed with internal combustion materials and shale soil at a weight ratio of 60:8:52, crushed, and sieved. Obtain the mixture; (3) transfer the mixture to the brick mixing system, and then add 15% by mass of tap water, drilling waste water, fracturing flowback water and gas and oil recovery waste water, or a mixture of at least two, Stir, shape, and make adobe; (4) Dry the adobe for 60 hours and send it to a brick kiln, sinter at 900°C for 15 hours, then cool and leave the kiln t...

Embodiment 3

[0043] A method for preparing sintered bricks from water-based drilling cuttings, comprising the steps of:

[0044] (1) Water-based drilling cuttings are automatically added into the sinking continuous reactor, and 1.0% of the mass percent modifier is added to the reactor for full reaction to obtain the reformed solid waste; (2) the modified solid waste The solid waste is transported to the brick factory, stacked and dried naturally for 5 days in the raw material area of the brick factory, and then the modified solid waste is mixed with internal combustion materials and shale soil at a weight ratio of 45:9:40, crushed, and sieved. Obtain the mixture; (3) transfer the mixture to the mixing system for brick making, then add a mixture of 12% by mass of tap water and drilling waste water, stir, shape, and make adobe; (4) dry the adobe for 55 hours and send it into The brick kiln is sintered at 1000°C for 12 hours, then cooled and discharged from the kiln to obtain the finished s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com