Slow rebound polyurethane foam sound insulation material

A sound insulation material and polyurethane technology, applied in the field of sound insulation, can solve the problems of slow curing, high difficulty, and increased cost, and achieve the effects of fast curing, ensuring openness and low hydroxyl value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Specific embodiments of the present invention are further described below:

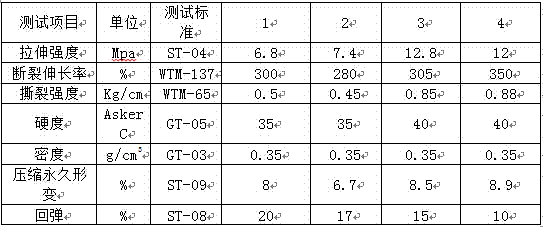

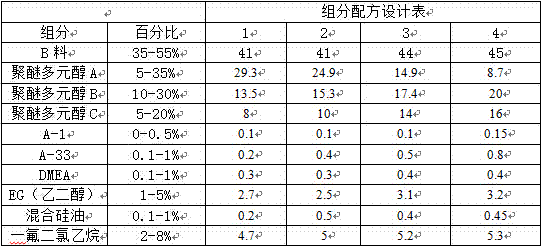

[0035] This proposal provides a slow rebound polyurethane foam sound insulation material, which is prepared from the following components by weight:

[0036] Material B: 35-55%;

[0037] Material A includes the following components: polyether polyol A: 5-35%; polyether polyol B: 10-30%; polyether polyol C: 5-20%; A-1: 0-0.5%; -33: 0.1-1%; DMEA: 0.1-1%; EG (ethylene glycol): 1-5%; mixed silicone oil: 0.1-1%;

[0038] The reason for adopting the above-mentioned preferred ratio formula is that mainly through the more refined ratio formula of various polyether polyols and catalysts among them, combined with a more reasonable ratio formula with other components, the interaction between each other can be brought into play. The synergistic effect makes the prepared material have better sound insulation performance and more uniform opening. The slow rebound polyurethane foam sound insulation materi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com