Char-forming agent based on tripiperazine-triazine and preparation method thereof

A technology of char-forming agent and piperazine, which is applied in the field of macromolecular char-forming agent and its preparation, can solve problems such as difficult removal and uncontrollable product structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

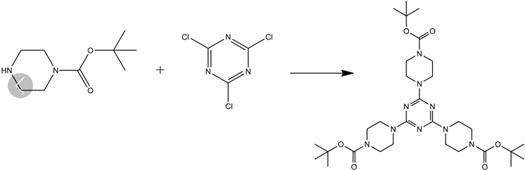

[0043] Example 1: Prepare a carbon-forming agent based on the tripiperazine-triazine structure according to the following steps

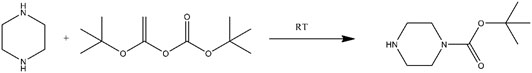

[0044] (1) Preparation of Boc-piperazine: Take 4.31g (0.05mol) of piperazine and add 100ml of CH at 25°C 2 Cl 2 In the solution, stir in a 250ml three-neck flask at a speed of 300r / min until uniform; 5.45g (0.025mol) of di-tert-butyl dicarbonate (Boc reagent), dissolved in 50ml of CH 2 Cl 2 The solution is placed in a constant pressure dropping funnel; after the piperazine dissolves, the Boc solution is added dropwise to the piperazine solution at a rate of 1-2 drops / s, and the temperature of the system is controlled at 25°C. React for 20h, TLC monitors the reaction end point; there will be a white precipitate during the dropwise addition, after the reaction is completed, the product is suction filtered to remove the white precipitate, and washed with water; the solution is transferred to a separatory funnel, and the 2 Cl 2 Extract three times,...

Embodiment 2

[0049] Example 2: Step (1)-step (3) is the same as Example 1; wherein, the preparation of step (4) prepolymer A2: take 2.40g (0.04mol) of ethylenediamine and add it to 60ml NMP solution at 20°C , while adding acid-binding agent pyridine 0.95g (0.012mol) and 5gCaCl 2 Stir in a three-necked flask at a speed of 300r / min until uniform, and the system passes through N 2 Protect and connect the tail gas absorption device; take phthaloyl chloride 9.34g (0.046mol) and dissolve it in 60ml NMP and place it in a constant pressure dropping funnel, drop the phthaloyl chloride solution at a rate of 1-2 drops / s Add it in the piperazine solution, control the system temperature at 25°C, continue to react for 0.5h after the dropwise addition, and obtain the solution of the prepolymer A2; step (5) preparation of the macromolecule char-forming agent: take 1.66g (0.005mol ) Tripiperazine-triazine is dissolved in 20ml NMP and placed in a constant pressure dropping funnel, after the prepolymer diss...

Embodiment 3

[0050] Example 3: Step (1)-step (3) is the same as Example 1; wherein, the preparation of step (4) prepolymer A2: take p-phenylenediamine 2.16g (0.02mol) and add 40ml NMP solution at 20°C , add 1.01g (0.01mol) of acid-binding agent triethylamine and 4g CaCl at the same time 2 Stir in a three-necked flask at a speed of 300r / min until uniform, and the system passes through N 2 Protect and connect the tail gas absorption device; take 5.07g (0.025mol) of isophthaloyl chloride and dissolve it in 40ml NMP and place it in a constant pressure dropping funnel, drop the isophthaloyl chloride solution at a rate of 1-2 drops / s Add it into the piperazine solution, control the system temperature at 40°C, continue to react for 1h after the dropwise addition, and obtain the solution of prepolymer A2; step (5) preparation of macromolecular char-forming agent: take 1.33g (0.004mol) Dissolve the tripiperazine-triazine in 20ml NMP and place it in a constant pressure dropping funnel; after the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com