Gasification technology burner protection device and protection method

A technology of process burner and gasifier, which is applied in the direction of gasification process, details of gasification device, chemical instruments and methods, etc., can solve the problem of reduced free volume of process burner chamber, easy damage of process burner, and reduced service life. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

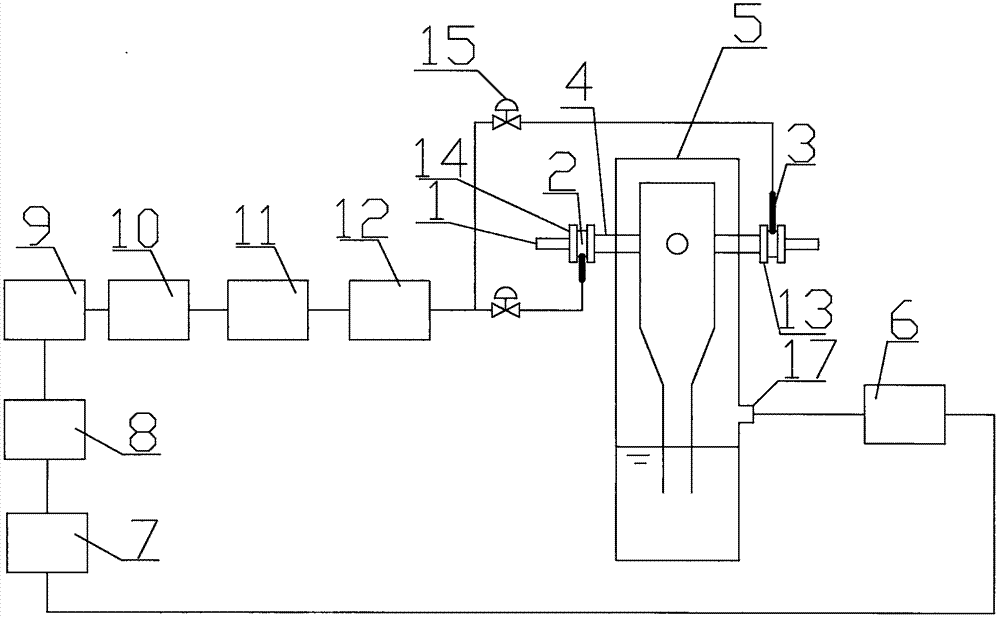

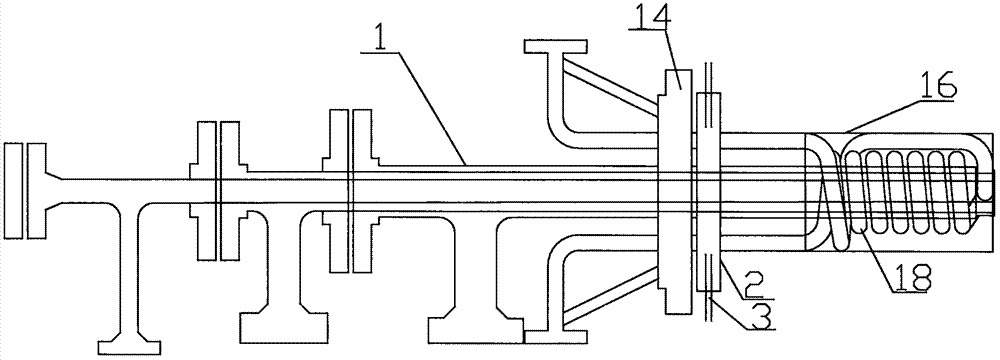

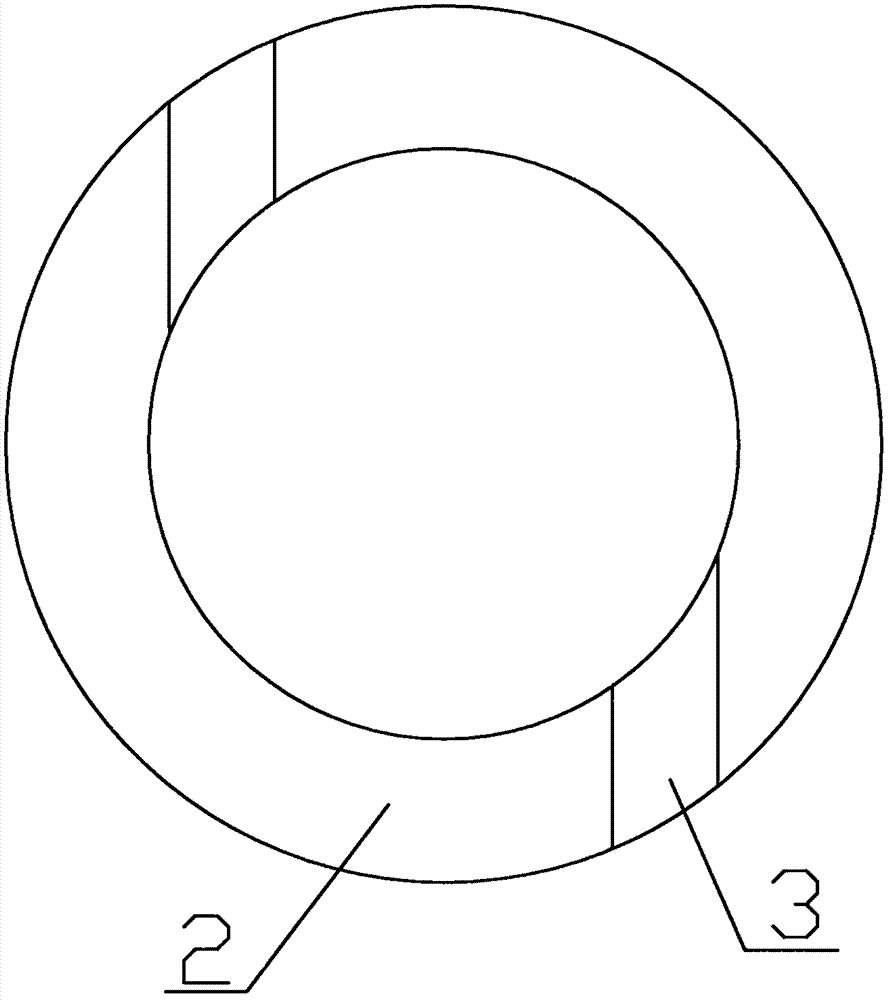

[0036] A protective gasification process burner device and protection method, wherein the protective gasification process burner device includes a gasification furnace 5, and several process burner chambers 4 are arranged on the upper part of the gasification furnace 5, and the process burner chamber 4 The gasification process burner is connected, and the bottom of the gasification furnace 5 is provided with a crude synthesis gas outlet 17, and the crude synthesis gas outlet 17 passes through the shift furnace 6 and CO 2 7 connected absorption towers, CO 2 The absorption tower 7 sequentially passes the CO 2 Analysis tower 8, CO 2 Compressor 9, first filter 10, second filter 11, heat exchanger 12 and regulating valve 15 and CO 2 The gasification process burner includes a process burner body 1 with coal slurry and oxygen channels. The front end of the process burner body 1 is provided with a cooling circulating water coil 18, and the cooling circulating water coil 18 The wate...

Embodiment 2

[0046] A protective gasification process burner device and protection method, wherein the protective gasification process burner device includes a gasification furnace 5, and several process burner chambers 4 are arranged on the upper part of the gasification furnace 5, and the process burner chamber 4 The gasification process burner is connected, and the bottom of the gasification furnace 5 is provided with a crude synthesis gas outlet 17, and the crude synthesis gas outlet 17 passes through the shift furnace 6 and CO 2 7 connected absorption towers, CO 2 The absorption tower 7 sequentially passes the CO 2 Analysis tower 8, CO 2 Compressor 9, first filter 10, second filter 11, heat exchanger 12 and regulating valve 15 and CO 2 The gasification process burner includes a process burner body 1 with coal slurry and oxygen channels. The front end of the process burner body 1 is provided with a cooling circulating water coil 18, and the cooling circulating water coil 18 The wate...

Embodiment 3

[0056] A protective gasification process burner device and protection method, wherein the protective gasification process burner device includes a gasification furnace 5, and several process burner chambers 4 are arranged on the upper part of the gasification furnace 5, and the process burner chamber 4 The gasification process burner is connected, and the bottom of the gasification furnace 5 is provided with a crude synthesis gas outlet 17, and the crude synthesis gas outlet 17 passes through the shift furnace 6 and CO 2 7 connected absorption towers, CO 2 The absorption tower 7 sequentially passes the CO 2 Analysis tower 8, CO 2 Compressor 9, first filter 10, second filter 11, heat exchanger 12 and regulating valve 15 and CO 2 The gasification process burner includes a process burner body 1 with coal slurry and oxygen channels. The front end of the process burner body 1 is provided with a cooling circulating water coil 18, and the cooling circulating water coil 18 The wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com