Microwave thermoacoustic detecting and monitoring system and method

A monitoring system and acoustic detection technology, which is applied in the fields of structural health monitoring, non-destructive testing and fault diagnosis, can solve the problems that the overall evaluation effect cannot be fully utilized, the acoustic emission signal cannot be enhanced, and the acoustic emission signal cannot be reproduced. Improve rapid defect imaging and quantitative capabilities, high monitoring efficiency, and achieve enhanced and reproducible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

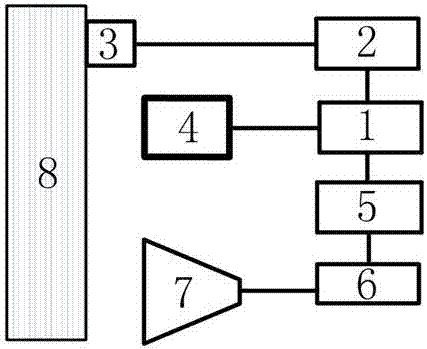

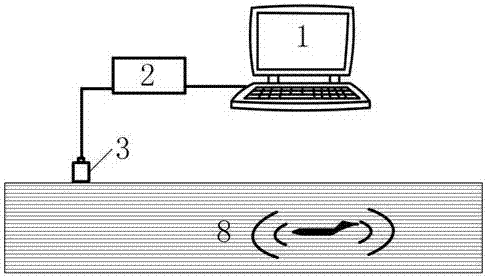

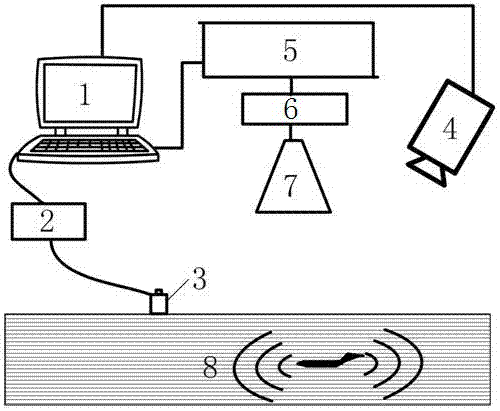

[0041] Such as Figure 1 to Figure 3 As shown, the microwave thermoacoustic detection and monitoring system includes a control system 1, an acoustic emission detector 2, an acoustic emission sensor array 3, a thermal imager 4, a microwave signal generator 5, a microwave signal amplifier 6 and a microwave antenna 7. The acoustic emission The sensor array 3 is arranged on the object 8 to be inspected, the field of view of the thermal imager 4 covers the area to be inspected of the object 8 to be inspected, the microwave antenna 7 is aimed at the area to be inspected of the object 8 to be inspected, and the acoustic emission sensor array 3. The acoustic emission detector 2 is electrically connected to the control system 1. The control system 1 is electrically connected to the microwave antenna 7 through the microwave signal generator 5 and the microwave signal amplifier 6. The control system 1 is electrically connected to the thermal imager 4.

[0042] The acoustic sensors in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com