Online continuous-oil-pipe nondestructive testing equipment based on flux leakage and ultrasound

A non-destructive testing and magnetic flux leakage testing technology, applied in measuring devices, analyzing solids using sonic/ultrasonic/infrasonic waves, and using sonic/ultrasonic/infrasonic waves for material analysis, etc. Problems such as poor working conditions and low reliability of test results can achieve the effects of small jitter, avoiding conversion errors and enhancing structural integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

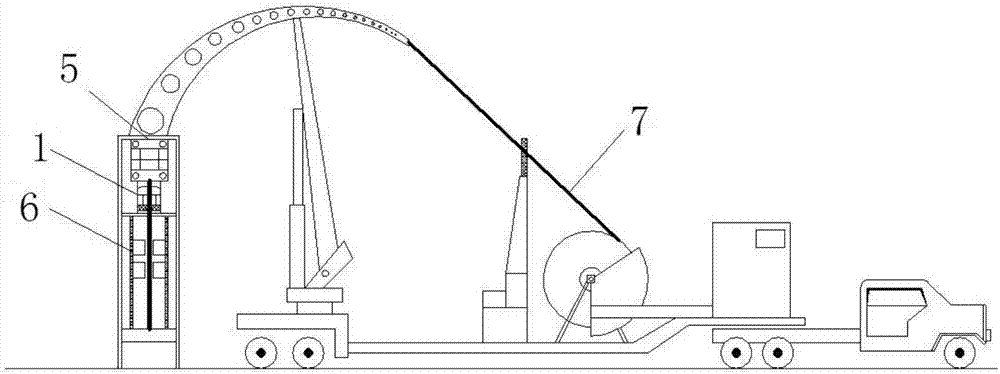

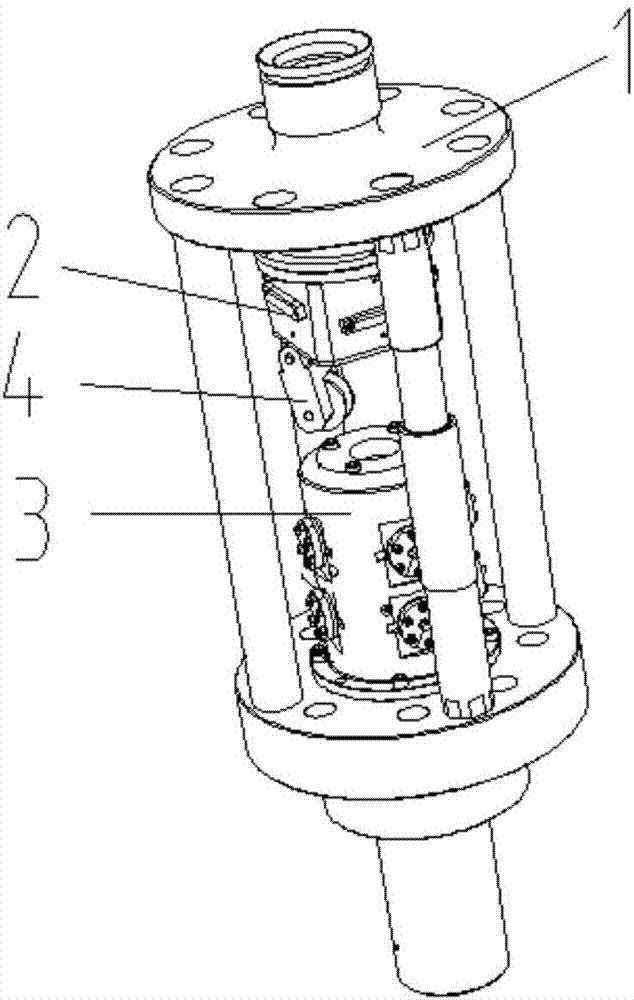

[0031] Such as Figure 1-12 As shown, the coiled tubing online non-destructive testing equipment based on magnetic flux leakage and ultrasonic in the present invention integrates the magnetic flux leakage detection unit 2, the ultrasonic detection unit 3 and the length measurement unit 4 into a casing main body 1, which is connected and fixed with the blowout preventer 6 , is installed between the blowout preventer 6 and the injection head 5, and it is detected online during the operation of the coiled tubing 7, such as figure 1 shown.

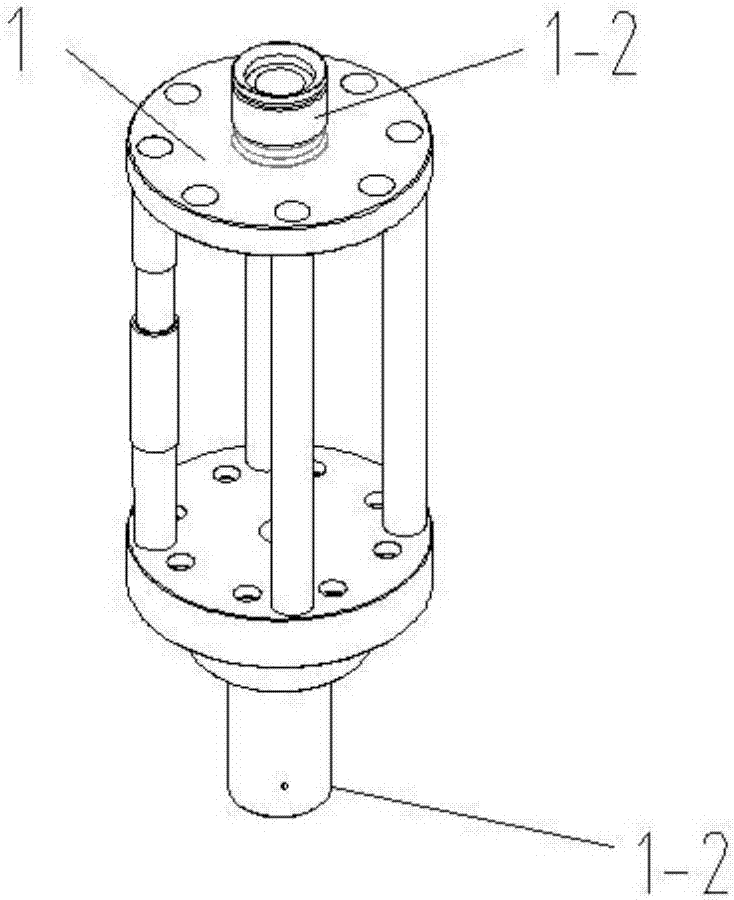

[0032] Such as figure 2 As shown, the coiled tubing online non-destructive testing equipment provided by the example of the present invention includes a casing main body 1 , a magnet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com