Method for tenderizing beef by using high voltage pulse electric field coupling technology

A high-voltage pulsed electric field and beef technology, which is applied in the fields of meat tenderization, meat softening through electric treatment, meat processing, etc., can solve the problems of no relevant reports, etc., and achieve the effect of good meat quality, fast speed, and obvious tenderization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

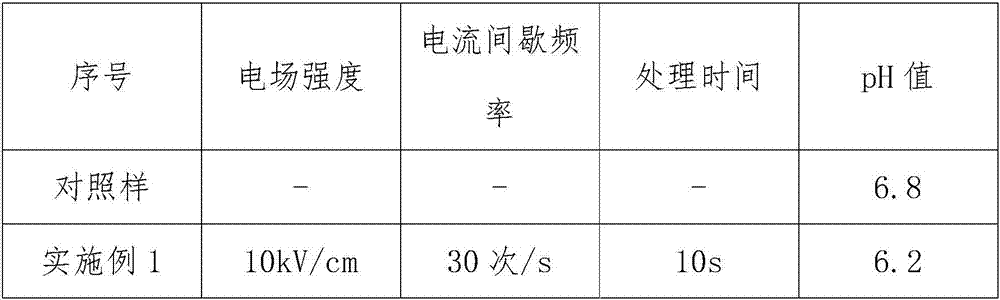

Embodiment 1

[0024] Step 1: Slaughter Heilongjiang yellow cattle aged 20 months and weighing about 400kg by conventional methods;

[0025] Step 2: Remove the fascia and fat from the outer tenderloin of the fresh beef, trim the edges neatly, and cut into slices, the size of the slices is 10cm×10cm×1cm;

[0026] Step 3: Roll and knead the gluten-removed beef for 5-8 minutes, dry it naturally, and perform tenderization.

[0027] Step 4: pH value measurement before high-voltage pulsed electric field treatment: three groups of cut meat slices were selected as test samples, and the pH value was measured. The measurement method is: insert the glass probe of the pH meter into the sample to be tested, measure the pH value of 3 different points, and take the average value.

[0028] Step 5: Measurement of shear force before high-voltage pulsed electric field treatment: measure the shear force of the three groups of samples respectively. The measurement method is as follows: remove the sample, wrap i...

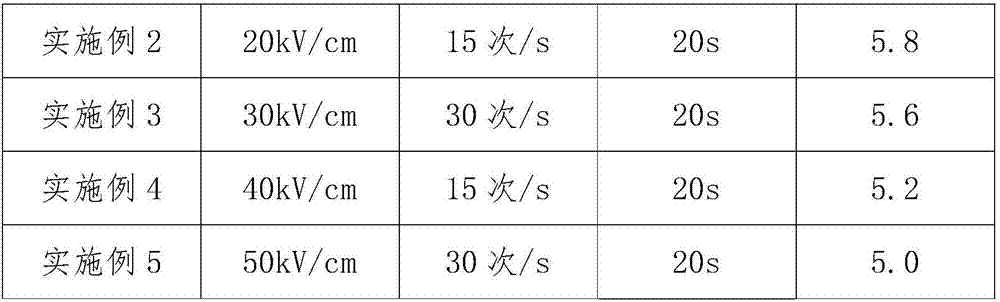

Embodiment 2

[0035] The method is basically the same as in Example 1, except that the pulse electric field intensity is 20kV / cm, the current intermittent frequency is 15 times / s, and the treatment time is 20s for high-voltage pulse electric field treatment.

Embodiment 3

[0037] The method is basically the same as in Example 1, except that the pulse electric field intensity is 30kV / cm, the current intermittent frequency is 30 times / s, and the treatment time is 20s for high-voltage pulse electric field treatment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com