Pretreatment system before spraying of aluminum alloy workpieces

A kind of pretreatment and aluminum alloy technology, applied in the direction of pretreatment surface, metal processing equipment, coating, etc., can solve the problems that cannot meet the use requirements, low efficiency, and quality can not be effectively guaranteed, so as to meet the pretreatment requirements , Easy to use and operate, and reduce difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

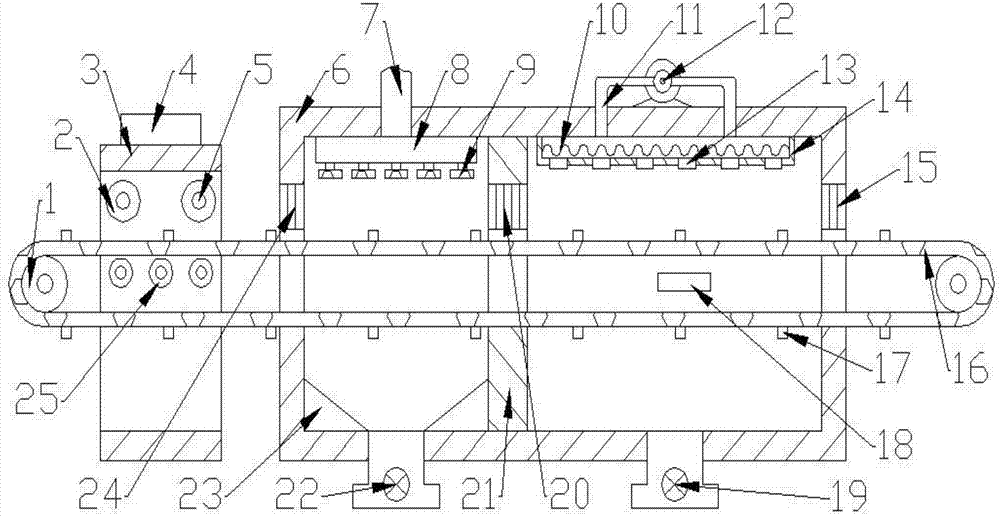

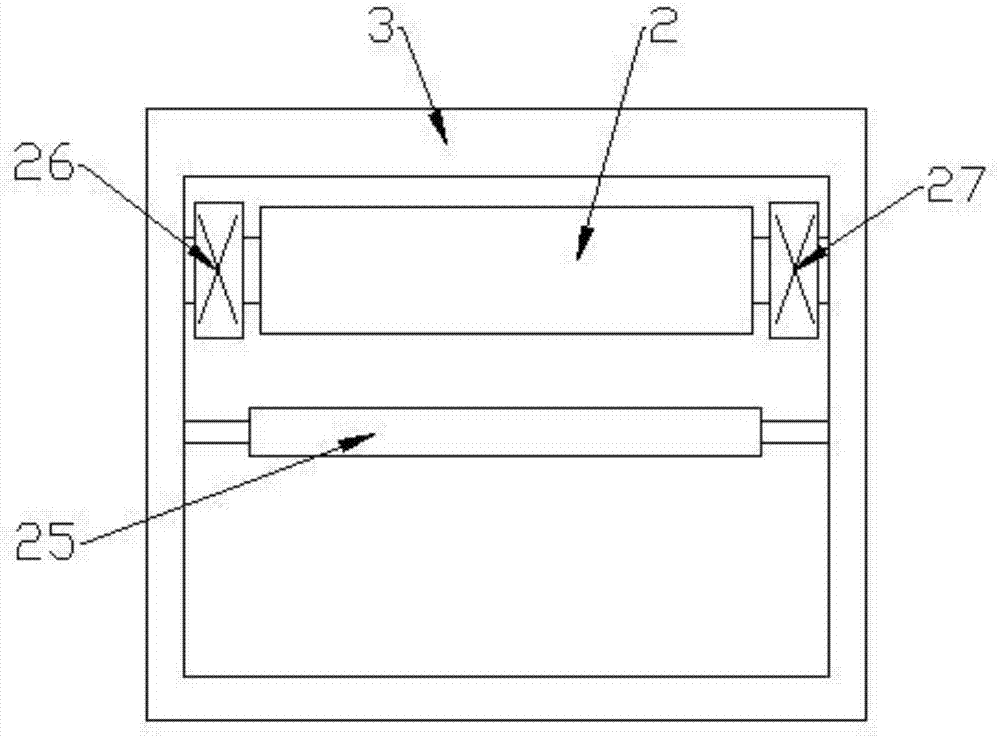

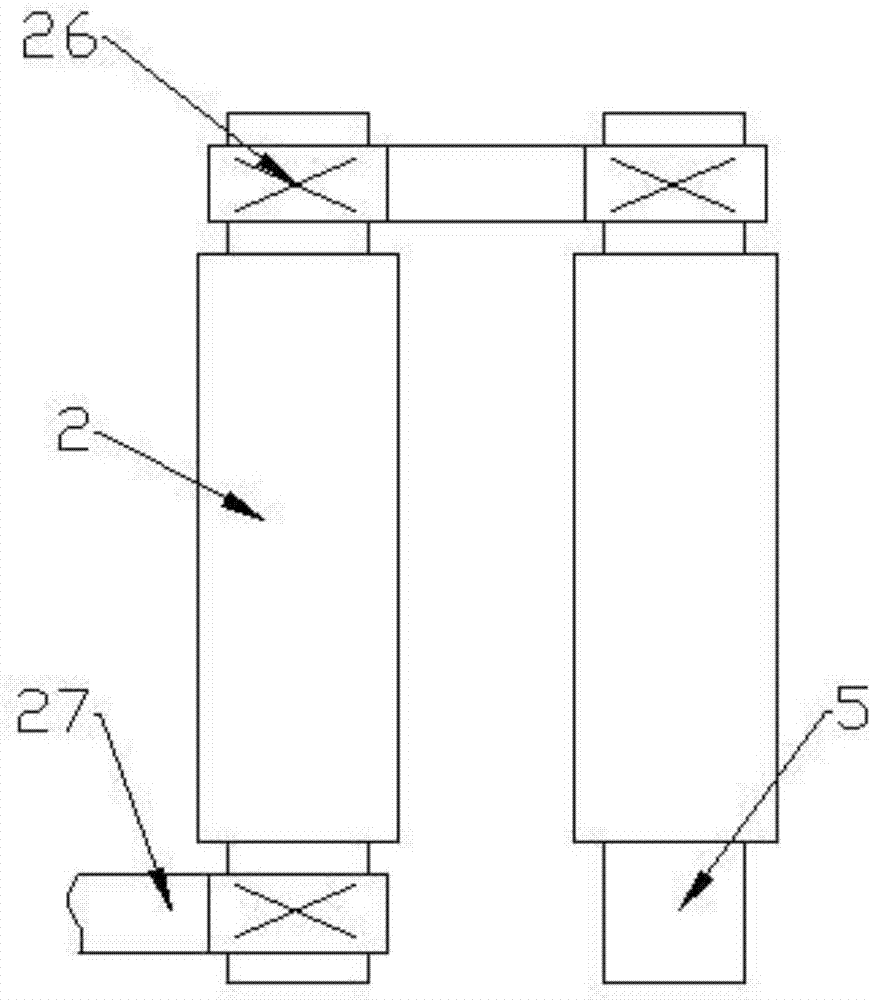

[0020] The technical solution of the present patent will be described in further detail below in conjunction with specific embodiments.

[0021] see Figure 1-4 , an aluminum alloy workpiece pretreatment system before spraying, comprising a protective frame 3; a power box 4 is fixed on the upper surface of the protective frame 3; the power box 4 is fixed to the connecting shaft 5 through a transmission pulley 27; Two shafts 5 are arranged vertically and fixed on the inner side of the protective frame 3, and are driven to rotate by the power box 4; the connecting shafts 5 are connected by a connecting pulley 26 to transmit rotational power; the grinding wheel roller 2 is installed on the connecting shaft 5; The grinding wheel roller 2 is driven and rotated by the connecting shaft 5 to grind the surface of the aluminum alloy; the bottom of the grinding wheel roller 2 is provided with a water permeable pulley 16; And its end is surrounded on the conveying wheel 1, and the alumin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com