Variable-amplitude constant-thickness sieve

A technology of equal thickness and amplitude, applied in the direction of filter screen, solid separation, grille, etc., can solve the problems of short residence time of materials at the discharge end, restrictions on efficient coal processing, and low utilization rate of the screen surface, so as to prolong the screening residence time Time, good economic and practical value, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

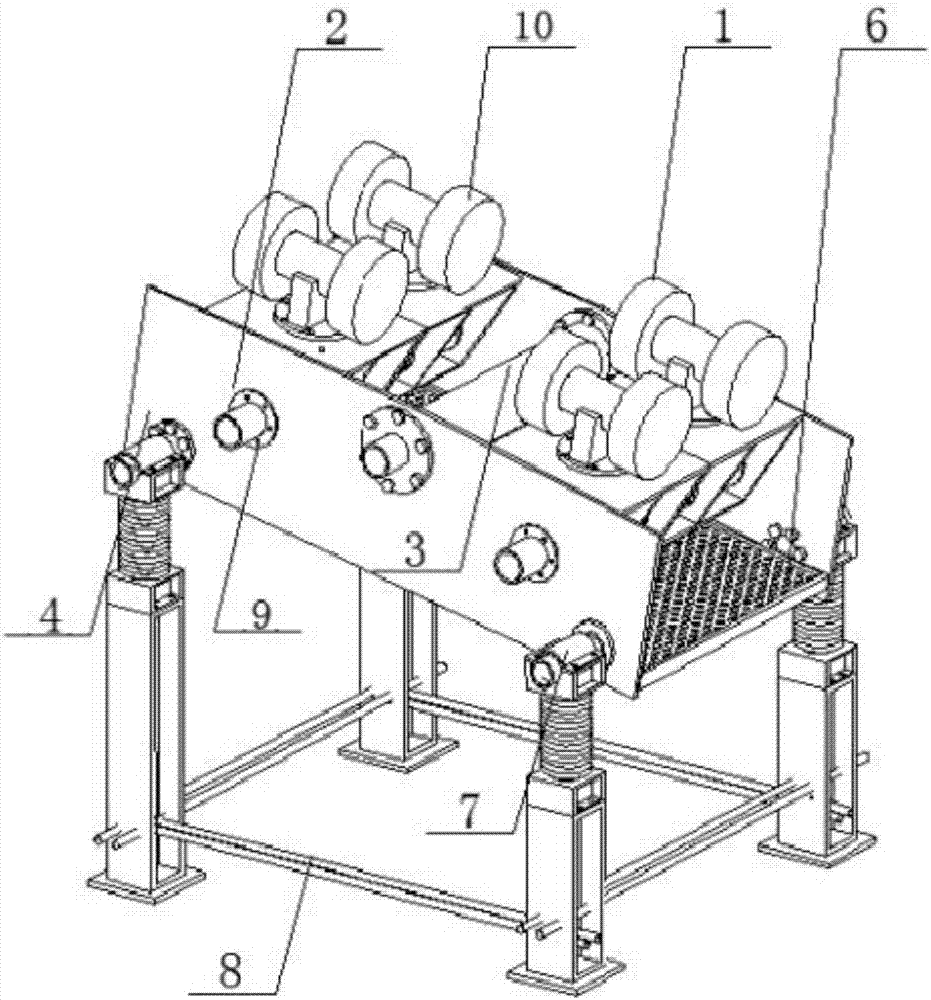

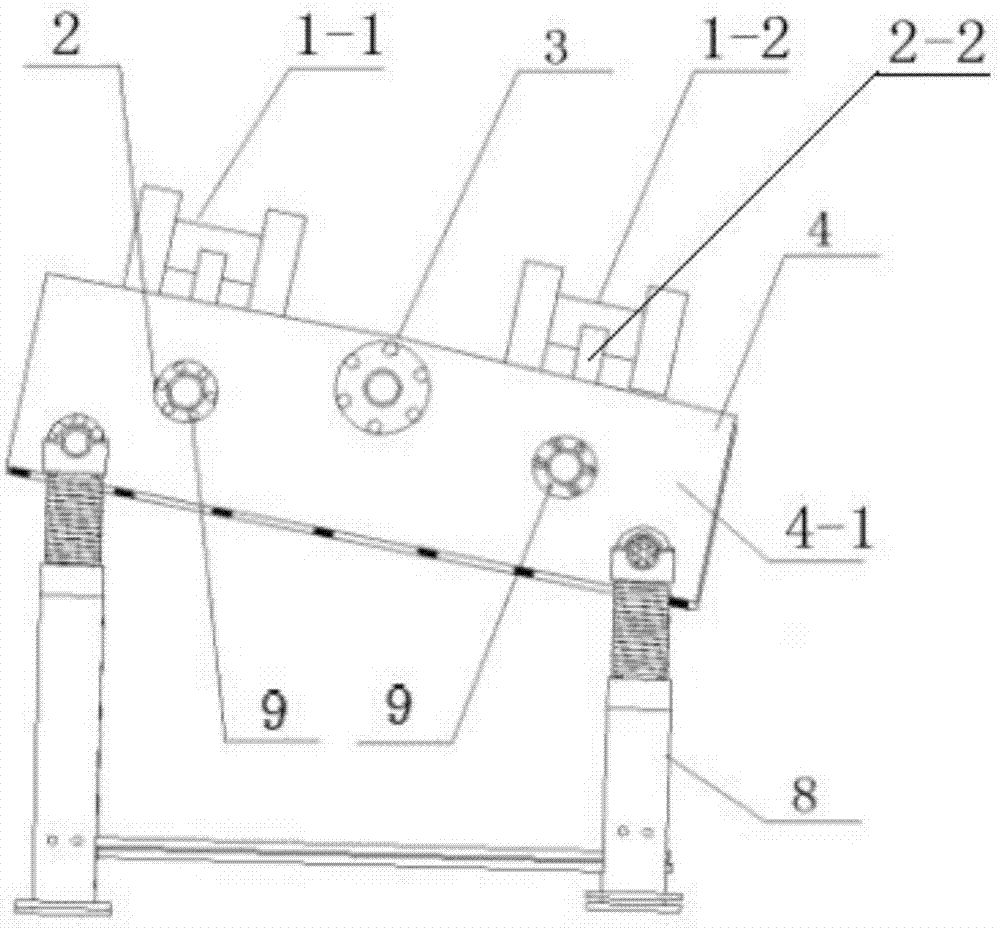

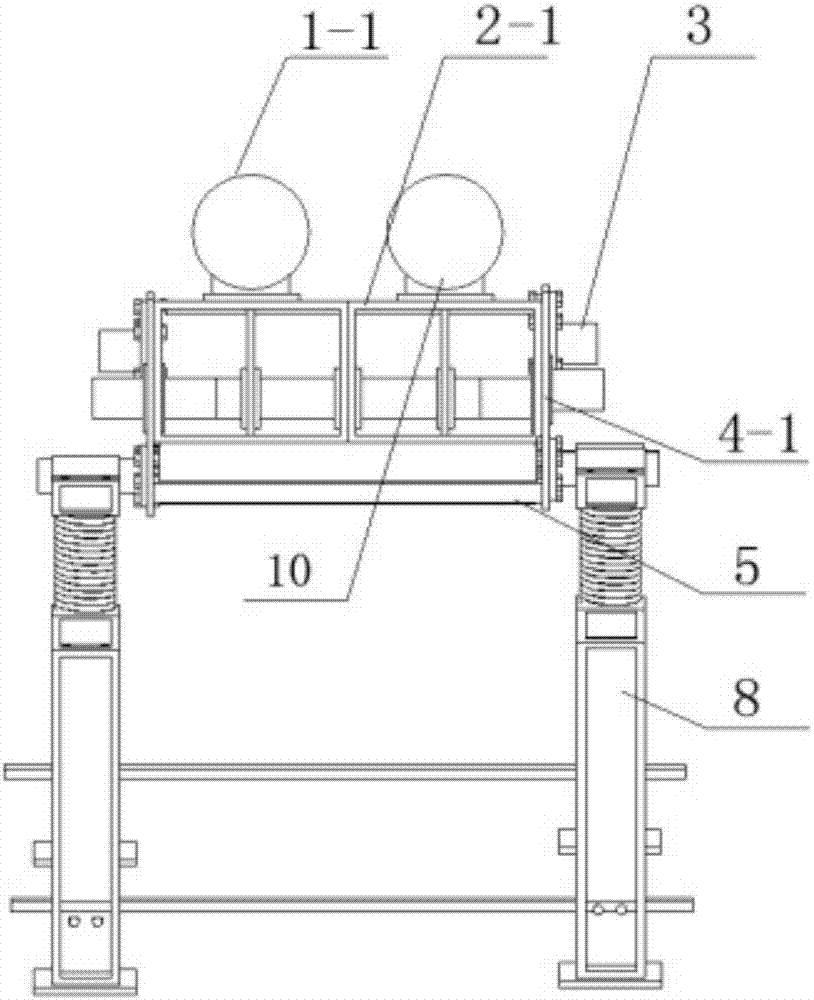

[0027] Before the variable-amplitude and equal-thickness screen runs, the two sets of exciting beams 2 can rotate at any angle around their centerlines, and then fasten the bolts through the circular distribution clamping holes and circular distribution bayonets to realize the mounting plate 9 and the side plate of the screen box. The rotation of 4-1 is fixed, the angle between the excitation direction of the exciter 1 on the excitation beam 2 and the horizontal plane is changed, and the amplitude and motion track of the vibrating screen body are adjusted so that the amplitude of the screen surface gradually increases from the feeding end to the discharging end. Reduce, and then realize the variable amplitude and equal thickness screening of materials.

[0028] After the variable-amplitude equal-thickness sieve runs stably, the screened material is fed from the feeding end, and the vibration intensity of the screen surface at the feeding end is increased through the feed-end vi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com