Power ultrasound device and method for iron mould sand coated production line casting mould

A technology of iron mold coating with sand and production line, applied in the field of metal material preparation, can solve the problem of casting quality not reaching the highest level, and achieve the effect of eliminating various defects, improving macro- and micro-segregation, and facilitating batch processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

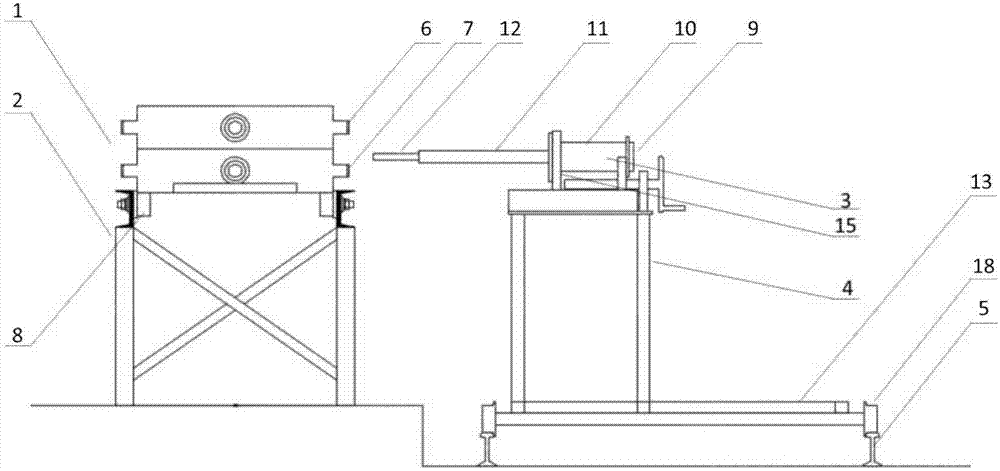

[0029] The power ultrasonic device used for casting molds in the iron mold sand-coated production line, the sand box 1 is located on the box rail 2; the track 5 is set parallel to the box rail 2; the ultrasonic processing device frame 4 is placed on the track 5 and moves horizontally along the track 5; The ultrasonic processing device 3 is fixed on the ultrasonic processing device frame 4 , and the ultrasonic processing device 3 is in close contact with the wall of the sand box 1 by adjusting the height of the ultrasonic processing device frame 4 . The sand box 1 includes an upper sand box 6 and a lower sand box 7, the upper sand box 6 and the lower sand box 7 are respectively provided with gates, runners and mold cavities, and the upper sand box 6 and the lower sand box 7 are combined and placed On the track of the box rail 2, a pulley A8 is arranged on the top of the box rail 2, and the lower sand box 7 contacts the box rail 2 through the pulley A8, and the sand box 1 is move...

Embodiment 2

[0033] Cover the cavity of the upper sand box 6 and the lower sand box 7 of the sand box 1 with sand. After the sand coating is completed, put the upper sand box 6 and the lower sand box 7 up and down to close the box, and use the fasteners to make the upper and lower sand boxes tight. In combination, the sand box after the box closing is completed is placed on the box rail 2.

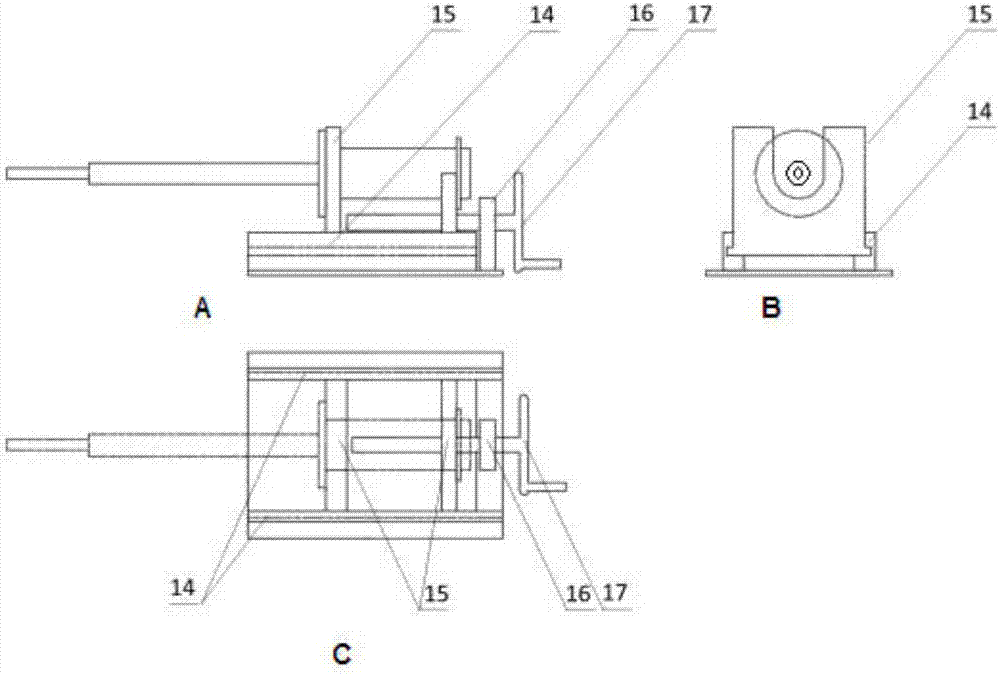

[0034] Fix the ultrasonic processing device 3 on the fixed frame 15 on the ultrasonic processing device frame 4, move the ultrasonic processing device frame 4 on the track 5, and the track 5 is parallel to the box rail 2; turn the hand wheel rotating rod 17 counterclockwise to make the ultrasonic processing device 3 Move away from the sand box 1 along the slide rail 14, pour the smelted metal into the sand box 1, adjust the ultrasonic processing device frame 4 to the middle part of the sand box 1, and turn the handwheel rotary rod 17 clockwise to make the ultrasonic processing device The ultrasonic pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com