Working table of computer numerical control machine tool

A technology of CNC machine tools and workbenches, applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve problems such as unfavorable cleaning, affecting the working environment, increasing the difficulty of cleaning, etc., to avoid flying everywhere, ensure clean, The effect of reducing workload and cleaning difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

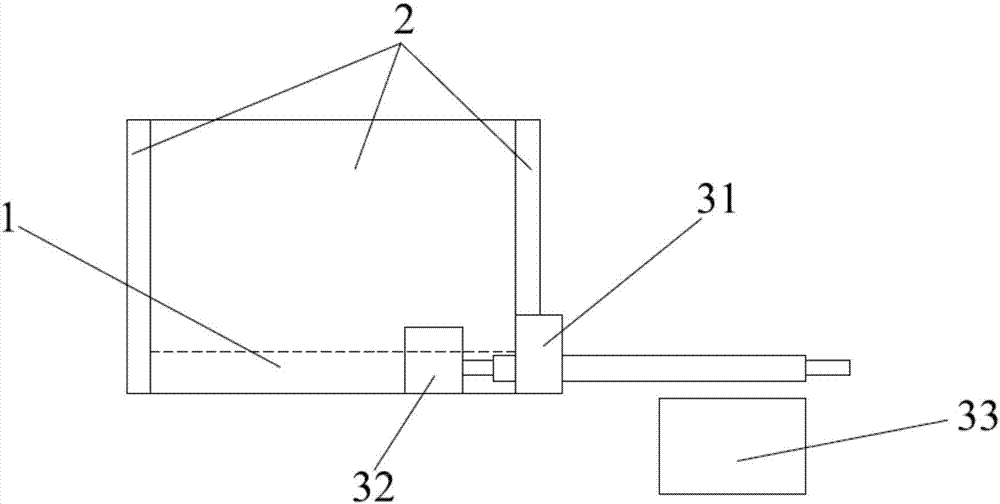

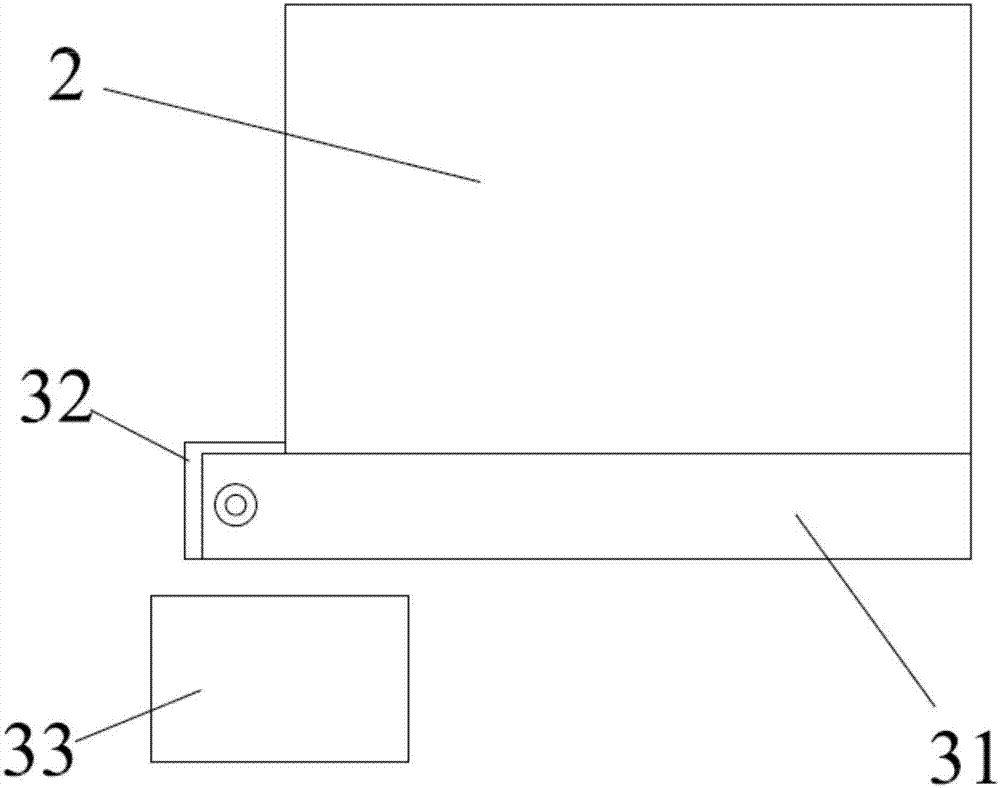

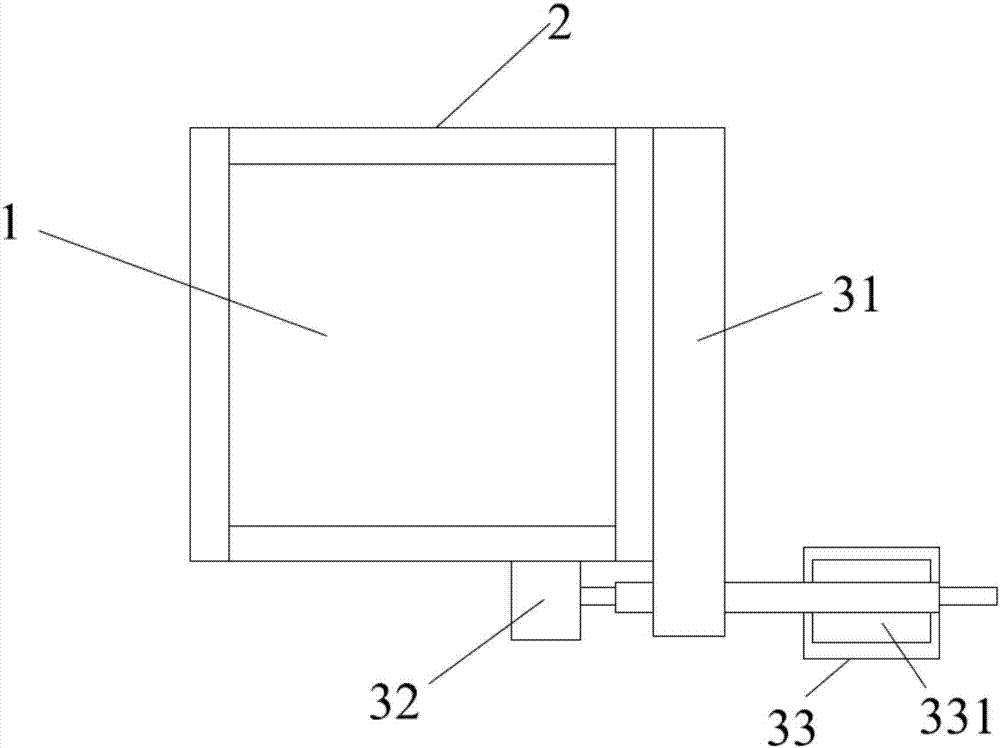

[0027] see Figure 1 ~ Figure 3 , the present invention provides a CNC machine tool workbench, which includes a workbench body 1 and a cleaning mechanism.

[0028] Specifically, the cleaning mechanism includes a cleaning baffle 2 and a cleaning assembly.

[0029] The cleaning baffle 2 is arranged around the outer surface of the workbench body 1, and the bottom of one side of the cleaning baffle 2 is vacant, and the bottom of this side is connected to the other two sides of the cleaning baffle 2 adjacent to this side. A chip outlet is formed between the side and the workbench body 1 , and the height of the cleaning baffle 2 is greater than that of the workbench body 1 .

[0030] The cleaning assembly includes an electromagnetic assembly, a linear reciprocating drive mechanism 32 and a recovery tank 33 with an opening 331 at the top. The electromagnetic assembly includes an electromagnet 31 connected in series and forming a loop, a power supply, a control switch, and a control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com