Device and method for preparing nano-kaolin

A nano-kaolin, preparation device technology, applied in chemical instruments and methods, nanotechnology, inorganic chemistry and other directions, can solve problems such as unfavorable industrial production, high cost, low yield, etc., achieve good peeling effect, good crystal structure, The effect of excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

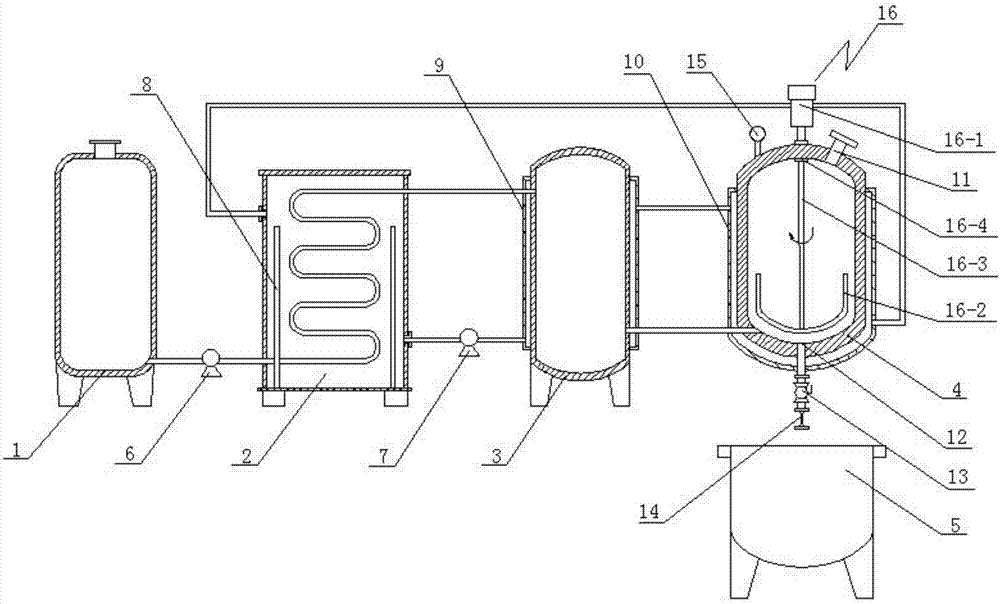

[0021] Such as figure 1 As shown, a nano-kaolin preparation device, wherein: including a carbon dioxide storage tank 1, a carbon dioxide heat exchanger 2, a buffer tank 3, a high-speed stirring tank 4, a collection tank 5, a high-pressure pump 6 and an oil pump 7;

[0022] The carbon dioxide heat exchanger 2 is provided with a heating pipe 8, and the bottom of the carbon dioxide heat exchanger 2 is provided with a safety valve; the outer wall of the buffer tank 3 is provided with a buffer tank heat exchange jacket 9, and the bottom of the buffer tank 3 is provided with a There is a pressure relief valve; the outer wall of the high-speed stirring tank 4 is provided with a stirring tank heat exchange jacket 10, the inside of the high-speed stirring tank 4 is provided with a stirring device 16, and the top of the high-speed stirring tank 4 is provided with a feed port 11 and pressure Count 15, the bottom of the high-speed mixing tank 4 is provided with a discharge port 12, the di...

Embodiment 2

[0033] Adopt the method for preparing nano-kaolin by the preparation device of nano-kaolin as described in Example 1, may further comprise the steps:

[0034] 1) Add appropriate amount of kaolin, intercalation agent and surface modifier into the high-speed stirring tank 4;

[0035] 2) The carbon dioxide gas in the carbon dioxide storage tank 1 is pressurized by the high-pressure pump 6 and enters the carbon dioxide heat exchanger 2, and the carbon dioxide gas enters the buffer tank 3 after being heated to 120°C in the carbon dioxide heat exchanger 2, and then enters the high-speed stirring tank 4;

[0036] 3) After the pressure in the high-speed stirring tank 4 reaches 20Mpa and the temperature reaches 120°C, start the stirring device 16 for stirring, the stirring speed is 800r / min, and the stirring time is 60min;

[0037] 4) After the stirring is completed, the discharge valve 13 is opened, and the material is discharged into the collection tank 5 through the discharge nozzle...

Embodiment 3

[0039] Adopt the method for preparing nano-kaolin by the preparation device of nano-kaolin as described in Example 1, may further comprise the steps:

[0040] 1) Add appropriate amount of kaolin, intercalation agent and surface modifier into the high-speed stirring tank 4;

[0041] 2) The carbon dioxide gas in the carbon dioxide storage tank 1 is pressurized by the high-pressure pump 6 and enters the carbon dioxide heat exchanger 2, and the carbon dioxide gas enters the buffer tank 3 after being heated to 100°C in the carbon dioxide heat exchanger 2, and then enters the high-speed stirring tank 4;

[0042] 3) After the pressure in the high-speed stirring tank 4 reaches 15Mpa and the temperature reaches 100°C, start the stirring device 16 for stirring, the stirring speed is 600r / min, and the stirring time is 40min;

[0043] 4) After the stirring is completed, the discharge valve 13 is opened, and the material is discharged into the collection tank 5 through the discharge nozzle...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap