Preparation method of high-performance M type calcium-strontium ferrite and product

A high-performance technology of strontium ferrite, applied in the field of preparation of calcium strontium ferrite, can solve the problems of unstable performance of calcium strontium ferrite, difficult control of production process, high price of rare earth elements, and avoid the formation of magnetic parts. Difficult, easy to control the production process, to avoid the effect of long-term grinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The preparation method of the high-performance M-type calcium strontium ferrite of the present invention comprises: a calcining process, after the calcining process, lithium carbonate powder is added to the calcined material. Here: the pre-sintered material can be ball-milled first, and then mixed with lithium carbonate powder; the pre-sintered material can also be mixed and ball-milled with lithium carbonate powder.

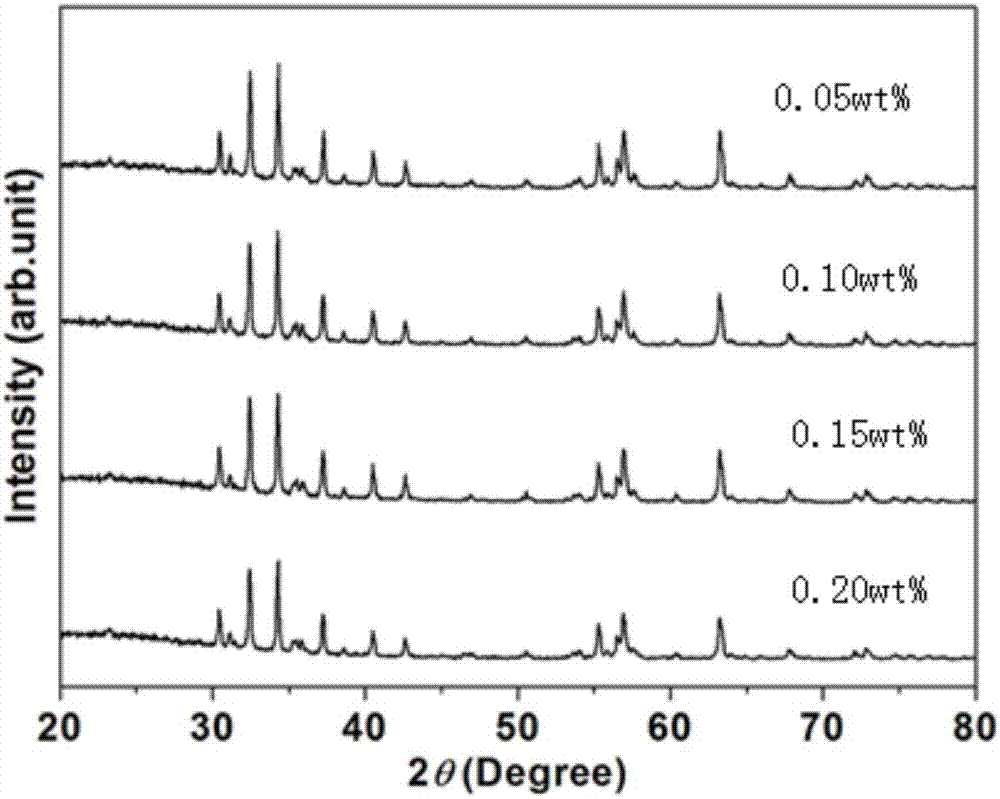

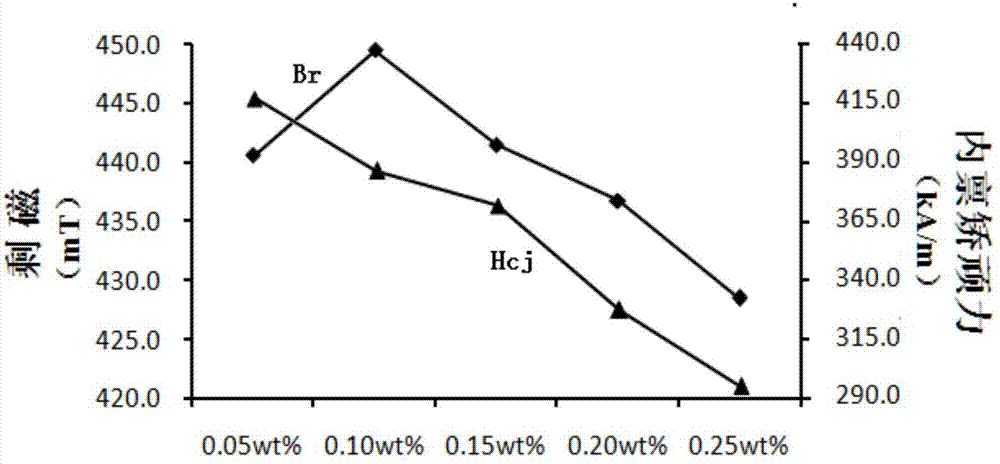

[0037] In the present invention, the calcined material and lithium carbonate powder are mixed and ball milled together, and the secondary ball milling process: the calcium strontium ferrite calcined material with an average particle size of 4 μm is used as raw material, lithium carbonate powder and dispersant are added, carbonic acid The amount of lithium powder added is 0.05-0.25wt% of the weight of the calcined material; ball: material: water = 15: 1: 2, ball milling on a rolling wet ball mill with a rotating speed of 80-100r / min, and the ball milling ti...

Embodiment 1

[0042] The preparation method of the high-performance M-type calcium strontium ferrite of the present invention comprises: (1) secondary ball milling process: take the calcium strontium ferrite calcined material with an average particle size of 4 μm as raw material, add lithium carbonate powder and dispersant , the addition of lithium carbonate powder is 0.05wt% of calcined material weight; Ball: material: water=15:1:2, ball milling on the rolling wet ball mill that rotating speed is 80r / min, ball milling time is 12h; Dispersant is The mixture of calcium gluconate and sorbitol, wherein the proportion of calcined feed weight is: 0.5% calcium gluconate, 0.8% sorbitol;

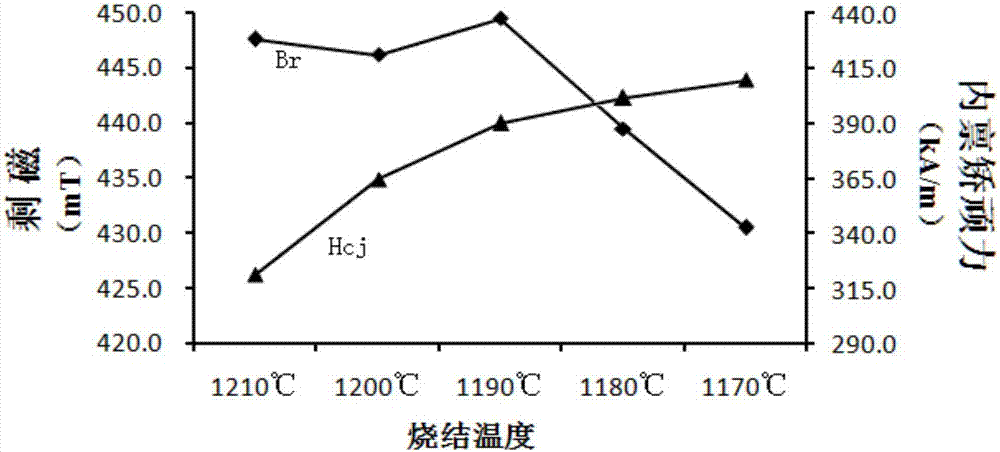

[0043] (2) Press green body process: adopt Fischer's average particle size measuring instrument to test its average particle size, slurry particle size is controlled at 0.8 μ m, then discharging, the water content of mixture is controlled at 30wt%; Slurry is pressed into blank, The forming magnetic field is 850kA...

Embodiment 2

[0047] The preparation method of the high-performance M-type calcium strontium ferrite of the present invention comprises: (1) secondary ball milling process: take the calcium strontium ferrite calcined material with an average particle size of 4 μm as raw material, add lithium carbonate powder and dispersant , the addition of lithium carbonate powder is 0.10wt% of calcined weight; Ball: material: water=15:1:2, ball milling on the rolling wet ball mill that rotating speed is 100r / min, ball milling time is 16h; Dispersant is The mixture of calcium gluconate and sorbitol, wherein the proportion of calcined feed weight is: 0.1% calcium gluconate, 0.3% sorbitol;

[0048] (2) Press green body process: adopt Fischer's average particle size measuring instrument to test its average particle size, slurry particle size is controlled at 0.8 μ m, then discharging, the water content of mixture is controlled at 40wt%; Slurry is pressed into blank, The forming magnetic field is 950kA / m and p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com