Preparation method of 6-chloro-2-nitrotoluene

A technology of nitrotoluene and o-nitrotoluene, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the problems of long chlorination reaction cycle, high production cost, and low reaction yield, and achieve Good economic and social benefits, short reaction cycle, and reduced side effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

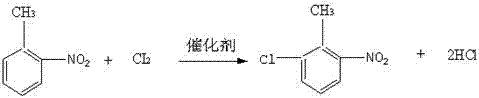

Image

Examples

Embodiment 1

[0018] 1. Chlorination step: Add 3300kg of o-nitrotoluene and 32kg of thionyl chloride into the chlorination kettle, turn on the tail gas absorption device, and stir at 63r / min. Feed vaporized chlorine into the chlorination kettle at a flow rate of 85kg / h, control the reaction temperature to be 65°C, react for 27 hours, and take samples for analysis. When the o-nitrotoluene content is 10%, after the chlorination reaction ends, the Blow compressed air in the kettle for about two hours to reduce the chlorine content in the chlorination kettle to obtain the primary product of 6-chloro-2-nitrotoluene. In the next operation, add new materials according to the specified amount, and start the next batch of chlorination reaction.

[0019] 2. Washing step: Add the measured 6-chloro-2-nitrotoluene primary product into the washing kettle, start the washing kettle to stir, add hydrochloric acid in the metering tank to the washing kettle, stir, let stand for 20min, separate layers, and cle...

Embodiment 2

[0028] Prepare according to the preparation method of 6-chloro-2-nitrotoluene in Example 1, only change the following parameters in the following steps of Example 1:

[0029] 1. Chlorination step: add 3300kg of o-nitrotoluene and 85kg of thionyl chloride to the chlorination kettle, turn on the tail gas absorption device, and stir at 63r / min. With the flow rate of 85kg / h, the vaporized chlorine gas is passed into the chlorination kettle, the control reaction temperature is 70°C, and the reaction is carried out for 27 hours. Sampling and analysis, when the o-nitrotoluene content is 10%, after the chlorination reaction ends, the Blow compressed air in the kettle for about two hours to reduce the chlorine content in the chlorination kettle to obtain the primary product of 6-chloro-2-nitrotoluene. In the next operation, add new materials according to the specified amount, and start the next batch of chlorination reaction.

[0030] 2. Washing step: Add the measured 6-chloro-2-nitro...

Embodiment 3

[0034] Prepare according to the preparation method of 6-chloro-2-nitrotoluene in Example 1, only change the following parameters in the following steps of Example 1:

[0035] 1. Chlorination step: add 3300kg of o-nitrotoluene and 155kg of thionyl chloride to the chlorination kettle, turn on the tail gas absorption device, and stir at 63r / min. With the flow rate of 85kg / h, the vaporized chlorine gas is passed into the chlorination kettle, and the reaction temperature is controlled to be 75°C, reacted for 27 hours, and sampling analysis is performed. Blow compressed air in the kettle for about two hours to reduce the chlorine content in the chlorination kettle to obtain the primary product of 6-chloro-2-nitrotoluene. In the next operation, add new materials according to the specified amount, and start the next batch of chlorination reaction.

[0036] 2. Washing steps: Add the measured primary product of 6-chloro-2-nitrotoluene into the washing kettle, start the washing kettle t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com