Polymer film for copper-plastic composite belt, copper-plastic composite belt and application of copper-plastic composite belt

A copper-plastic composite tape and polymer film technology, which is applied in the field of communication materials, can solve the problems of short service life, reduced service life, limited application range, etc., and achieves the effects of excellent moisture resistance, improved film formation and wide application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A polymer film for a copper-plastic composite tape, consisting of the following components:

[0035] 90 parts of modified EVA;

[0036] 10 parts of ethylene acrylic acid copolymer;

[0037] Antioxidant 0.01 part;

[0038] Wherein, modified EVA is made up of ethylene-octene thermoplastic elastomer and EVA base material, and ethylene-octene thermoplastic elastomer accounts for 1wt%; The content of acrylic acid in the ethylene-acrylic acid copolymer is 2wt%; Antioxidant is three ( 2. 4-Di-tert-butylphenyl)phosphite.

[0039] A copper-plastic composite tape is formed by wrapping the above-mentioned copper-plastic composite tape with a polymer film on the outside of a copper tape layer, and the thickness ratio of the polymer film to the copper tape layer is 10:1.

Embodiment 2

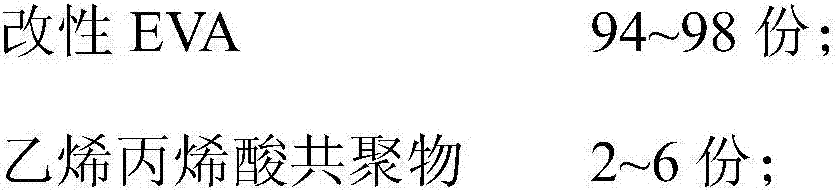

[0041] A polymer film for a copper-plastic composite tape, consisting of the following components:

[0042]

[0043] Among them, the modified EVA is composed of ethylene-propylene rubber and EVA substrate, and the proportion of ethylene-propylene rubber is 10wt%; the content of acrylic acid in the ethylene-acrylic acid copolymer is 10wt%; the antioxidant is 2,6-di-tert-butylphenol; The pigment is phthalocyanine.

[0044] A copper-plastic composite tape is formed by wrapping the above-mentioned copper-plastic composite tape with a polymer film on the outside of the copper tape layer, and the thickness ratio of the polymer film to the copper tape layer is 1000:1.

Embodiment 3

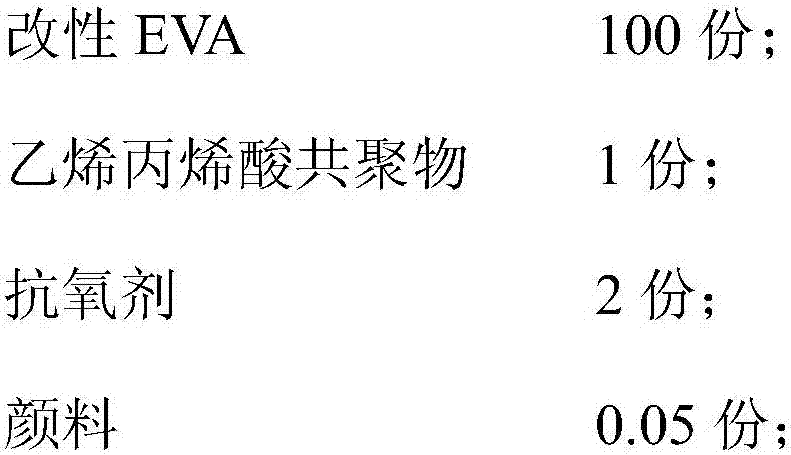

[0046] A polymer film for a copper-plastic composite tape, consisting of the following components:

[0047]

[0048]

[0049] Among them, the modified EVA is composed of styrene-butadiene-styrene rubber and EVA substrate, and the proportion of styrene-butadiene-styrene rubber is 2wt%; the content of acrylic acid in the ethylene acrylic acid copolymer is 5wt%; The antioxidant is 4,4'-thiobis(6-tert-butyl m-cresol); the pigment is phthalocyanine.

[0050] A copper-plastic composite tape is formed by wrapping the above-mentioned copper-plastic composite tape with a polymer film on the outside of the copper tape layer, and the thickness ratio of the polymer film to the copper tape layer is 100:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com