Production method of cigarette smoke gas sensitive color change fragrance release particles

A production method and technology for cigarette smoke, which are applied in the fields of tobacco, fat production, and tobacco preparation, can solve problems such as inability to guarantee mechanical strength, and achieve the effects of high mechanical strength and effective anti-counterfeiting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

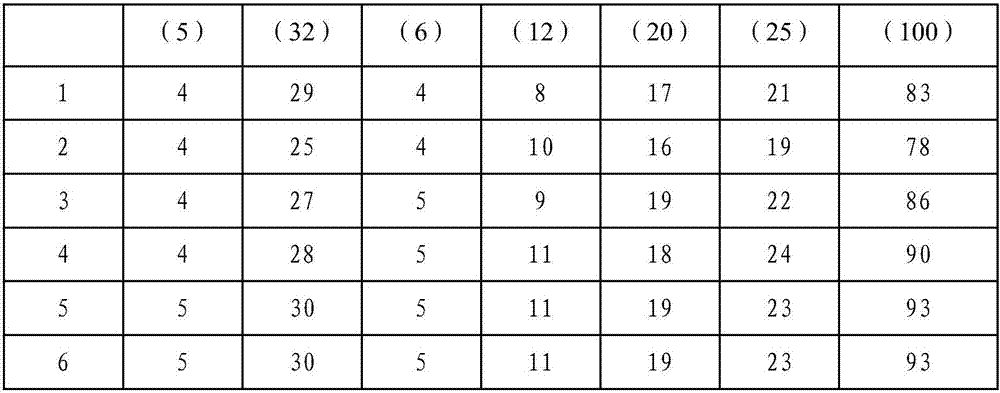

Embodiment 1

[0055] Example 1: Production of Cigarette Smoke Sensitive Discoloration and Flavor Release Granules

[0056] The implementation steps of this embodiment are as follows:

[0057] A. Prepare the mixture

[0058] According to the weight ratio of color-changing powder and binder of 1:50, and the weight ratio of binder and main material of 3:7, use a stirring device to bond red-to-orange color-changing powder, porous starch plant starch main material and microcrystalline cellulose The agent is mixed evenly to obtain a mixture;

[0059] B. Parcel

[0060] According to the weight ratio of the mixture to the pellet core for cigarettes is 5:20, add the pellet core for cigarettes to the disc granulator, and sprinkle the mixture obtained in step A on the cigarette while the disc granulator is rotating. On the pellet core, spray 46% of the weight of the mixture at the same time, so that the mixture is evenly adhered and wrapped on the pellet core for smoking, and the pellet core for ciga...

Embodiment 2

[0063] Example 2: Production of Cigarette Smoke Sensitive Discoloration and Flavor Release Granules

[0064] The implementation steps of this embodiment are as follows:

[0065] A. Prepare the mixture

[0066] According to the weight ratio of color-changing powder and binder of 1:80, and the weight ratio of binder and main material of 2:6, use a stirring device to glue the green-turning-yellow coloring powder, polyethylene glycol 1000 main material and hydroxymethyl starch The binder is mixed evenly to obtain a mixture;

[0067] B. Parcel

[0068] According to the weight ratio of the mixture to the pellet core for cigarettes is 5:6, add the pellet cores for cigarettes to the disc granulator, and sprinkle the mixture obtained in step A on the cigarette while the disc granulator is rotating. On the pellet core, spray 20% of the weight of the mixture at the same time, so that the mixture is evenly adhered and wrapped on the pellet core for smoking, and the pellet core for ciga...

Embodiment 3

[0071] Example 3: Production of Cigarette Smoke Sensitive Discoloration and Flavor Release Granules

[0072] The implementation steps of this embodiment are as follows:

[0073] A. Prepare the mixture

[0074] According to the weight ratio of color-changing powder and binder of 1:120, and the weight ratio of binder and main material of 1:5, use a stirring device to mix brown-red color-changing powder, potato starch plant starch main material and polyacrylic resin binder Mix evenly to obtain a mixture;

[0075] B. Parcel

[0076] According to the weight ratio of the mixture to the pellet core for cigarettes is 5:16, add the pellet core for cigarettes to the disc granulator, and sprinkle the mixture obtained in step A on the cigarette pellets while the disc pelletizer is rotating. On the pellet core, spray 32% of the weight of the mixture at the same time, so that the mixture is evenly adhered to and wrapped on the pellet core for cigarettes, to obtain a pellet core for cigar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com