Software test system and method for digital reactor protection system of nuclear power plant

A technology for reactor protection and system software, applied in the field of nuclear power, can solve the problems of limited test automation, single test path, low parameter value coverage, etc., and achieve the effect of automatic generation and full coverage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

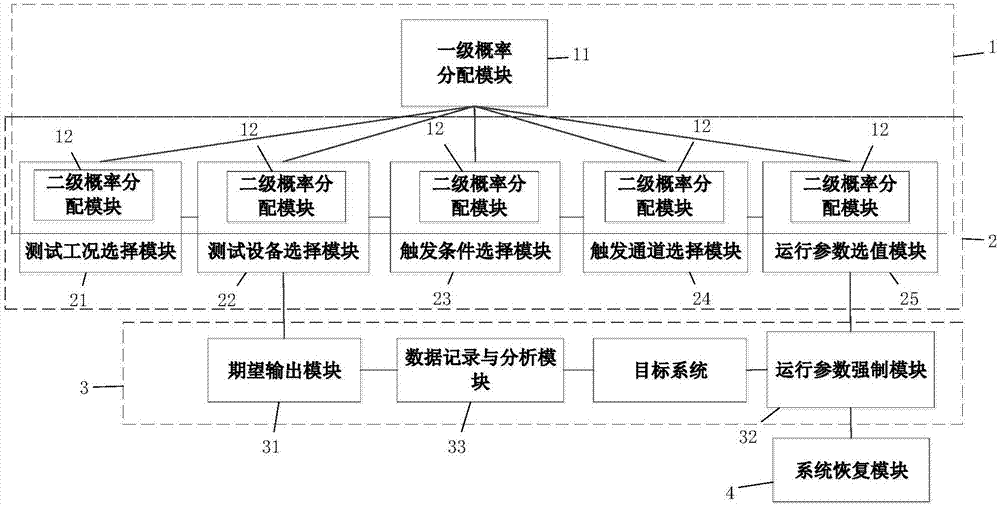

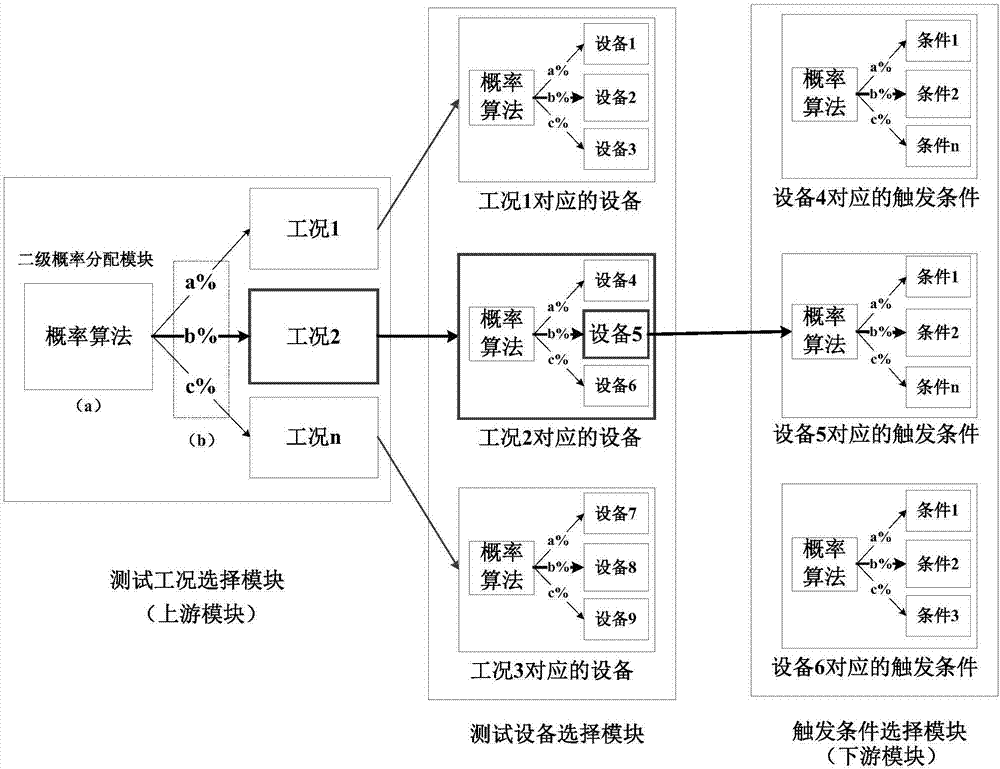

[0055] Such as figure 1 As shown, the nuclear power plant digital reactor protection system software testing system provided by the present invention includes: a probability distribution component 1, which is used to distribute the probabilities of multiple selection modules of the parameter generation component 2 through calculation, and is used to assign each The branch selection of the next step of the selection module is selected to carry out probability distribution; the parameter generation component 2 includes a plurality of selection modules and is respectively connected with part of the probability distribution component 1, and is used to assign components according to the probability in each round 1, select the test working conditions, test equipment, trigger conditions, test channels and input parameters, and generate the expected value of each round of testing according to the corresponding operating test equipment; the data analysis component 3 is connected with th...

Embodiment 2

[0063] Such as Figure 4 As shown, Embodiment 2 of the present invention provides a method for testing software of a nuclear power plant digital reactor protection system, including the following steps:

[0064] S1. Probabilities are assigned to multiple branch steps in step S2 by calculation, and the branch steps selected in this round are determined;

[0065] S2. Select the test working conditions, trigger conditions and test channels, and generate the expected value and operating parameter value of each round of testing according to the corresponding operating parameter interval;

[0066] S3. Analyzing and comparing the expected value and the operating parameter value of each round, customizing statistics and exporting the test results of each round.

Embodiment 3

[0068] Such as Figure 5 As shown, the step S1 includes:

[0069] S11. When the test is started, allocate and determine the branch probability and algorithm in the step S2, specifically determine the probability algorithm and branch probability (%) of the branch step in the step S2.

[0070] S12. Perform calculation according to the probability and algorithm allocated in step S11, and confirm the branch to be selected in this round.

[0071] Specifically, the step S2 includes:

[0072] S21. Select the working conditions to be tested in this round from the preset nuclear power plant working conditions;

[0073] S22. Among the various protective equipment or actions under the selected working conditions, select the equipment or actions that need to be tested in this round;

[0074] S23. Select the trigger condition to be tested in this round from the preset trigger conditions under the selected working conditions;

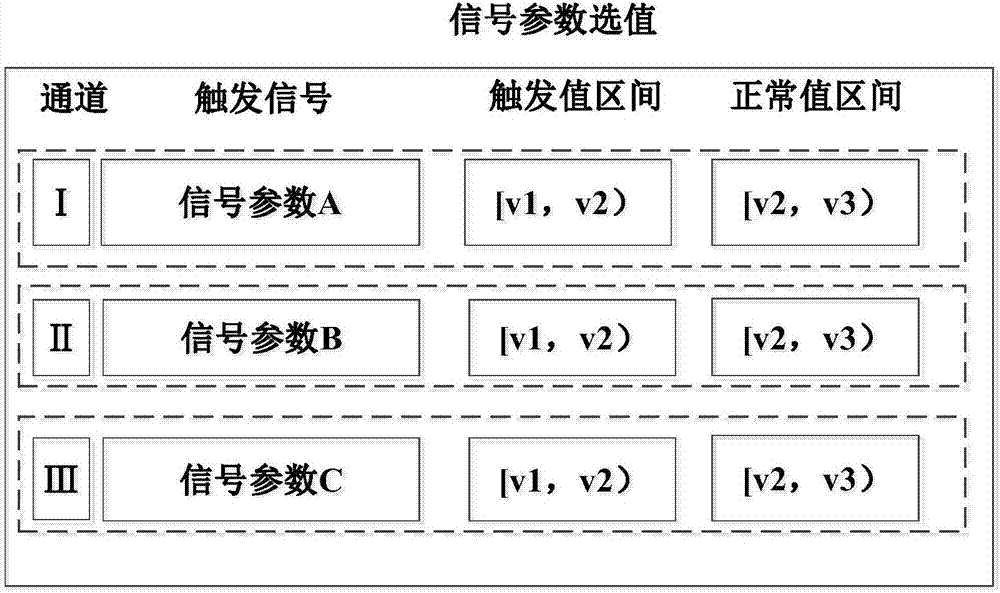

[0075] S24. Select a trigger channel for this round of test...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com