A hybrid packaging method for semiconductor devices

A hybrid packaging and semiconductor technology, used in semiconductor devices, semiconductor/solid-state device manufacturing, electric solid-state devices, etc., can solve the problems of high cost and low production efficiency, achieve easy operation, improve welding quality, and good adhesion performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

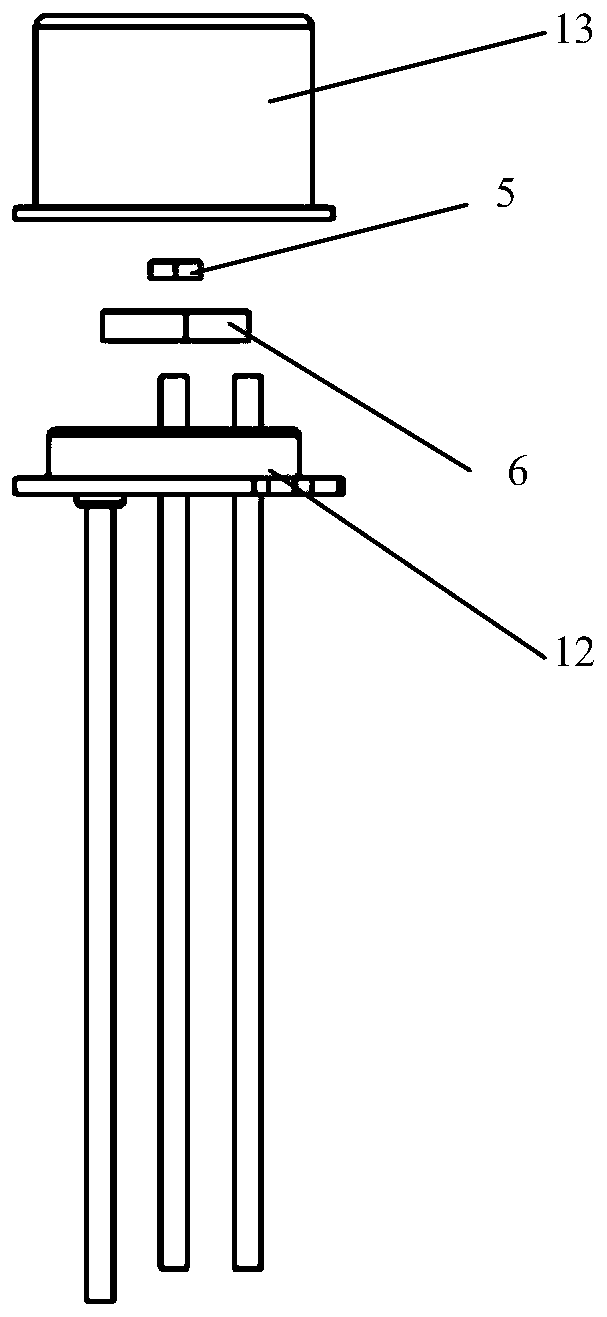

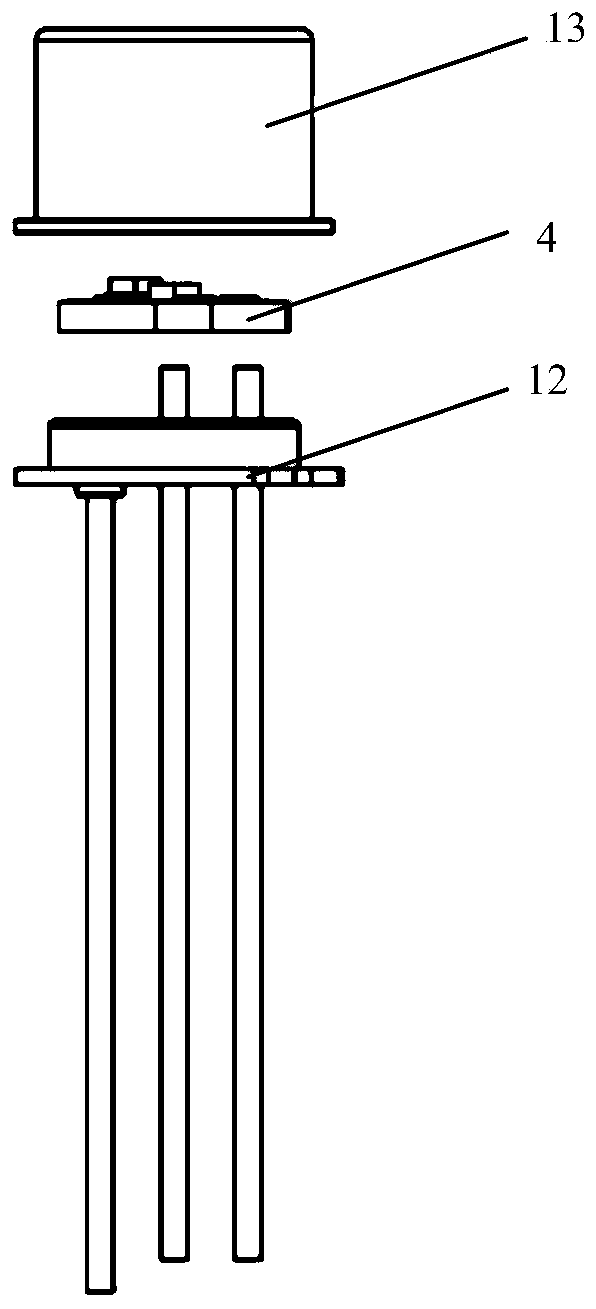

[0043] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0044]It should be noted that in the present invention, since the semiconductor device is easily damaged due to electrostatic shock, the entire packaging process needs to be carried out in an antistatic environment to avoid product quality defects caused by static electricity during the packaging process.

[0045] A semiconductor device hybrid packaging method, comprising the steps of:

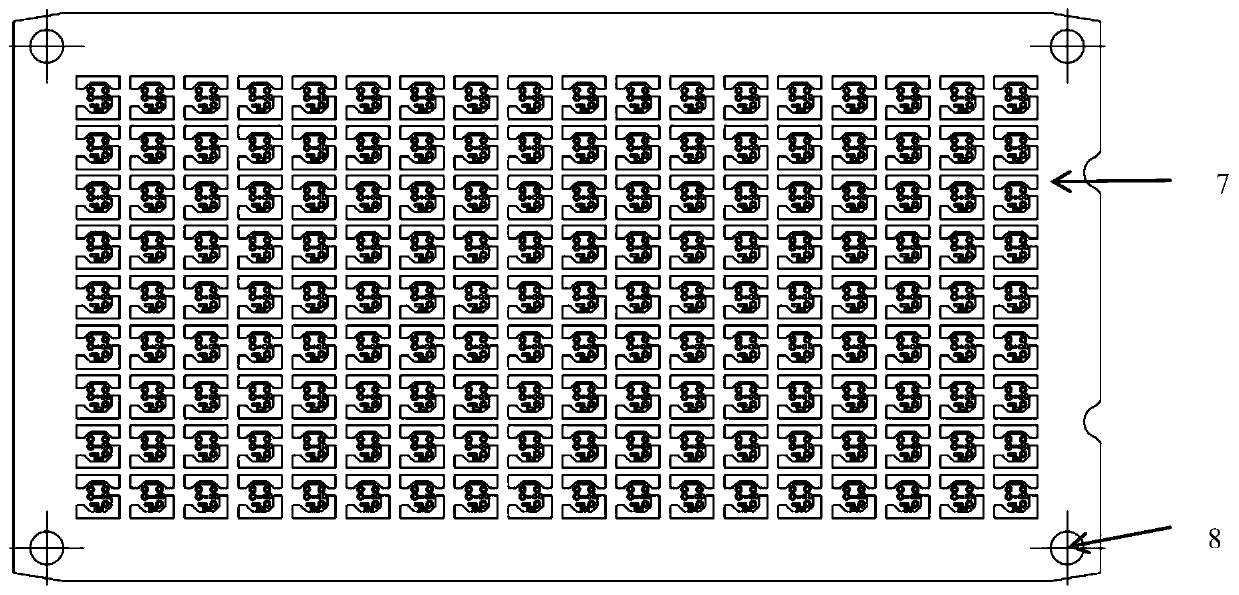

[0046] Step 1: Make a PCB board 7 composed of a skeleton and several small PCB boards 4 arranged on the skeleton, fix components on each of the small PCB boards 4, and connect the components with the corresponding The PCB small board 4 is welded;

[0047] Such as image 3 and Figure 7 As shown, in this embodiment, the components...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com