Micro LED device and manufacturing method thereof

A technology of LED devices and manufacturing methods, which is applied to semiconductor devices, electric solid devices, instruments, etc., can solve problems such as complexity, long process flow, and inability to achieve micron levels, and achieve the effect of convenient operation and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

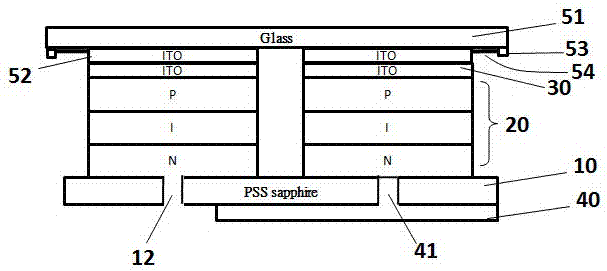

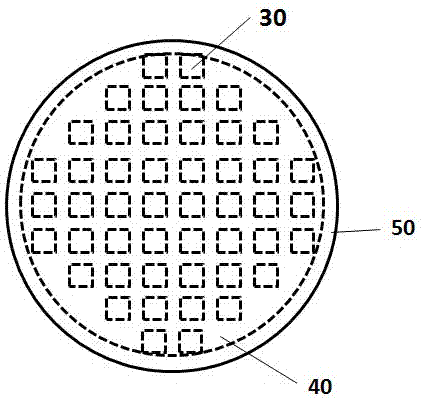

[0043] See attached figure 1 In one aspect, the present invention discloses a micro LED device, which at least includes a substrate 10, a plurality of LED elements arranged at intervals on the substrate 10, a plurality of LED elements share a substrate 10, and are periodically arranged on the substrate 10 on (eg figure 2 As shown), there are a plurality of through holes 12 penetrating the substrate at positions corresponding to the LED elements inside the substrate 10, and a metal back plate 40 is provided on the back of the substrate 10, and the metal back plate 40 has a plurality of protrusions corresponding to the through holes 12. The protrusion 41 is inserted into the through hole 12 and is electrically connected to the epitaxial wafer 20, and a transparent cover plate 50 is placed on the surface of the LED element. The material of the substrate 10 can be sapphire, silicon carbide, silicon, etc., and can be a patterned substrate, or a flat substrate. In this embodiment,...

Embodiment 2

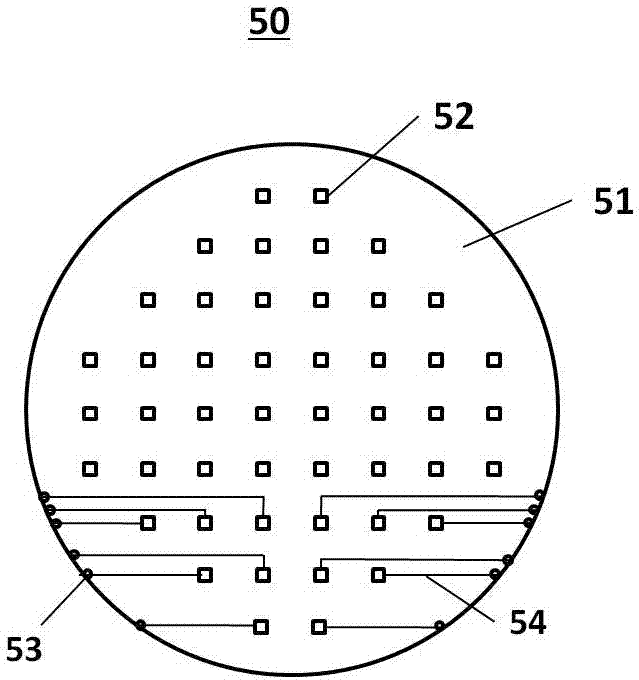

[0063] See attached Image 6 In this embodiment, in order to improve the heat dissipation effect of the micro-LED device, the metal backplane 40 may be configured to be composed of a plurality of electrically isolated sub-metal backplanes 42 . Each sub-metal backplane 42 corresponds to each LED element, conductive spacer 52 , metal contact 53 , and conductive wire 54 , with the same number.

[0064] In the micro-LED device, each metal contact 53 corresponds to an LED element and a sub-metal backplane 42, therefore, equivalent to a parallel structure of LED elements, the light emission of a single LED element can be individually controlled.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com