Fuel cell stack

A fuel cell stack and single cell technology, which is applied in fuel cell additives, fuel cell heat exchange, fuel cell components, etc., can solve the problems of poor heat dissipation, increased power consumption, and increased cooling fan air volume, etc., to achieve Fast cooling effect, weight reduction, and performance-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

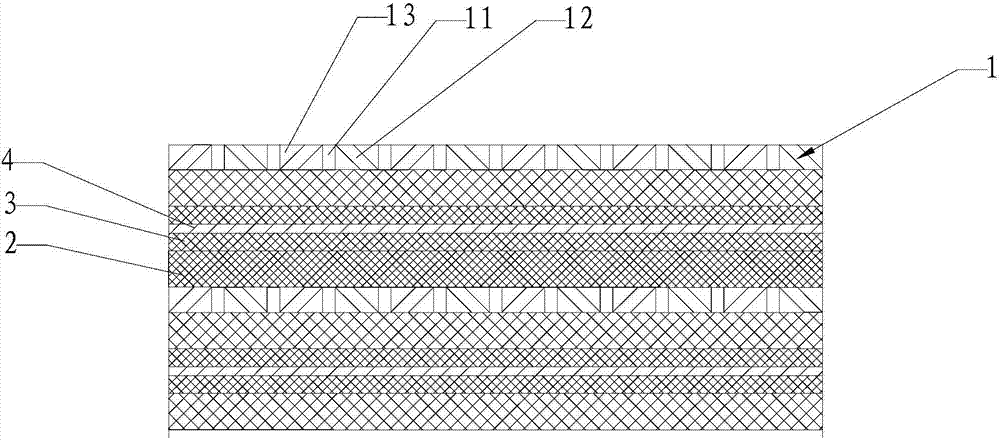

[0028] A fuel cell stack, which is an air-cooled proton exchange membrane fuel cell stack, includes a bipolar plate 1, a membrane electrode, a current collector plate and an end plate, and the bipolar plate 1 and the membrane electrode constitute a single cell. A single cell is stacked together with a collector plate and an end plate to form a fuel cell stack, wherein the membrane electrode includes a diffusion layer 2, a catalytic layer 3 and a proton exchange membrane 4, and the catalytic layer 3 and the diffusion layer are respectively placed on both sides of the proton exchange membrane 4. 2. Diffusion layer 2, catalytic layer 3 and proton exchange membrane 4 are stacked by hot pressing to form membrane electrodes. The bipolar plate 1 includes an upper hydrogen guide layer and a lower air guide layer, a heat dissipation channel is provided between the hydrogen guide layer and the air guide layer, and a vertical supporting main layer is arranged on the heat dissipation chann...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com