Ferromagnetic lamination sheet, motor, magnetic conductive part and winding structure of motor, and wind generating set

A technology of magnetic conductive parts and motor windings, which is applied in the direction of wind power motor combination, wind power engine, and motor generator manufacturing. It can solve the problems of large elastic modulus gap, damage to insulation, and failure to prevent damage to insulation, so as to ensure structural integrity. and strength, the effect of preventing peeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

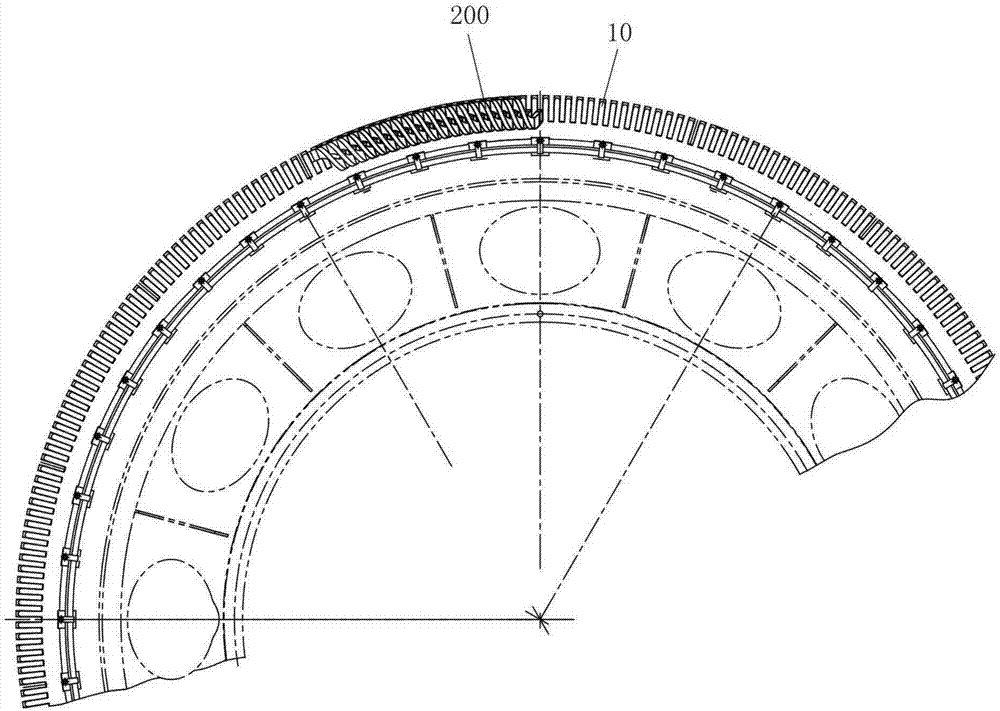

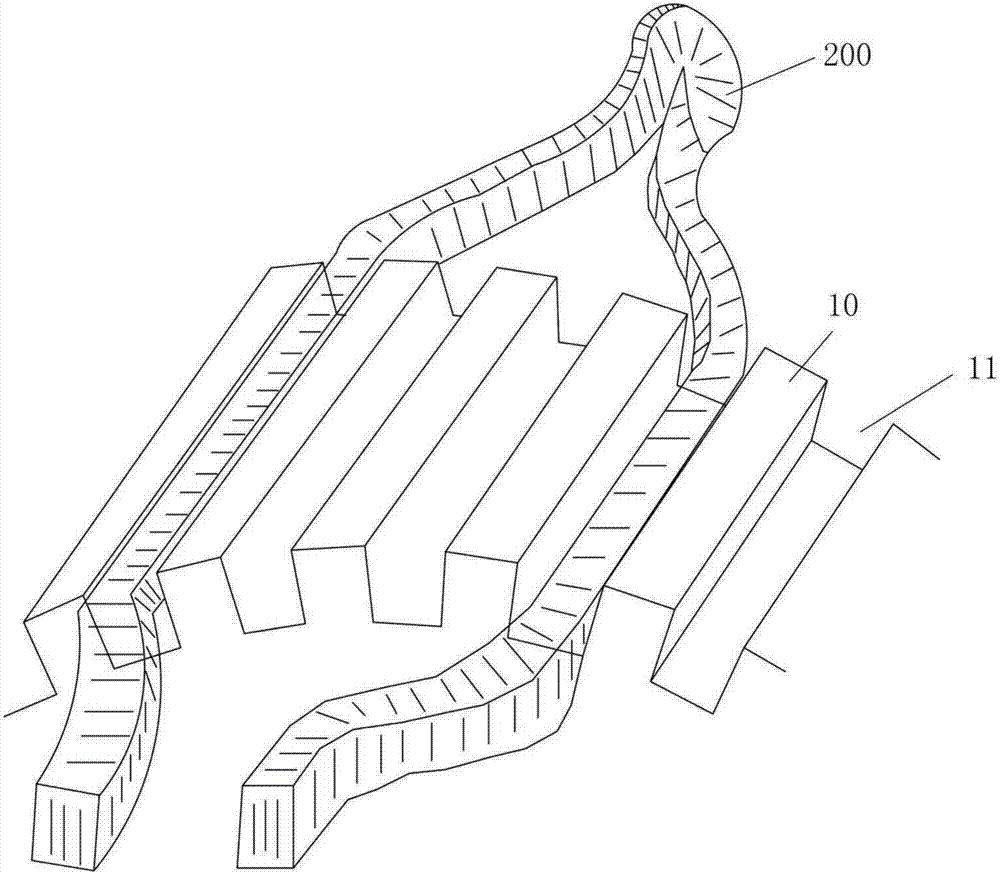

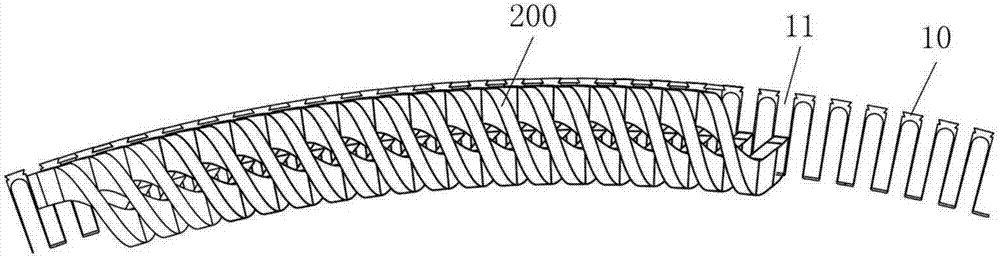

[0063] In order to solve the problem that the liquid insulating medium is not easy to remain in the magnetic conductive parts of the motor when the magnetic conductive parts of the motor in the prior art are insulated, and the insulation is caused when the magnetic conductive parts of the motor expand and contract due to temperature changes. The problem that the dielectric layer is squeezed or stretched to separate or tear from the surface of the magnetic conductive component, the present invention improves the structure of the ferromagnetic boundary of the traditional winding from the perspective of interdisciplinary seepage mechanics, and forms a new type of boundary on the ferromagnetic boundary Structure-The cavity structure, with the help of the automatic formation of the vacuum space in the cavity and automatically prevents the liquid insulating medium from flowing, so as to retain and fix the liquid insulating medium. And after the liquid insulating medium is solidified a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com