Spiral double-water flow channel cooling high-power density permanent magnet synchronous motor

A permanent magnet synchronous motor, high power density technology, applied to synchronous motors with stationary armatures and rotating magnets, synchronous machine parts, cooling/ventilation devices, etc., can solve the problem of inability to ensure complete sealing and uneven heat dissipation of the motor , affect the heat dissipation effect and other issues, to achieve excellent temperature control effect, significant cooling effect, and good heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

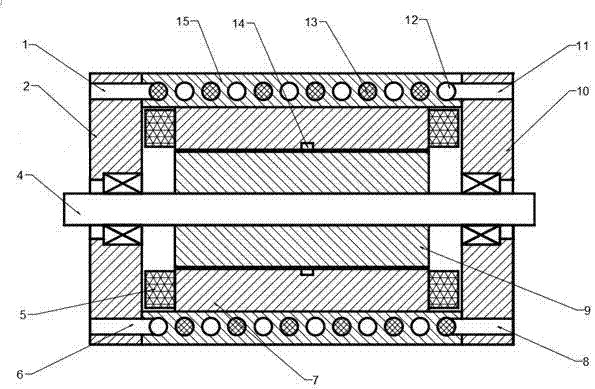

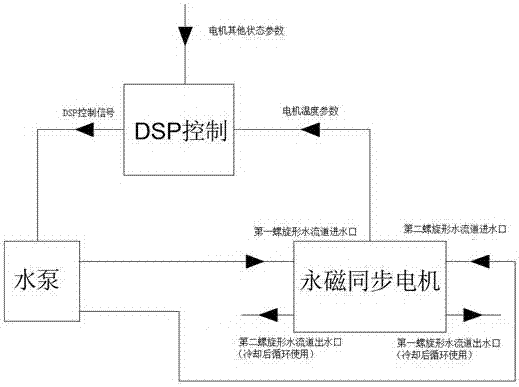

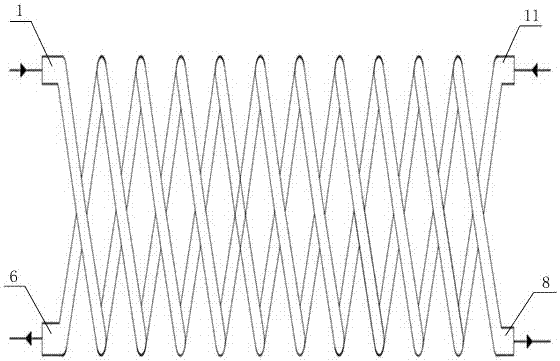

[0020] like figure 1 , figure 2 and image 3 As shown, the present invention includes a stator, a rotor and a heat dissipation system. The stator is mainly composed of a stator core 7, a stator winding 5, a casing 15, a front end cover 2 and a rear end cover 10, and the rotor includes a rotor core 9 and a rotating shaft 4 , the heat dissipation system is composed of a temperature sensor 14, a DSP control chip, a first spiral water flow channel 12, a second spiral water flow channel 13 and a water pump, and the first spiral water flow channel 13 and the first spiral water flow channel are arranged in the casing 15. The second spiral water channel 12 with reverse flow, the front cover 2 is provided with the water inlet 1 of the first spiral water channel and the water outlet 6 of the second spiral water channel, and the rear end cover 10 is provided with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com