Manufacturing method of dehydrated vegetable crisp chips

A technology of dehydrated vegetables and a production method, which is applied in the direction of preservation of fruits/vegetables through dehydration, food science, etc., can solve the problems of inconvenient processing methods of dehydrated vegetables, poor taste, loss of vegetable nutrients or active ingredients, etc., and achieve bright color , excellent quality, and the effect of loss reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

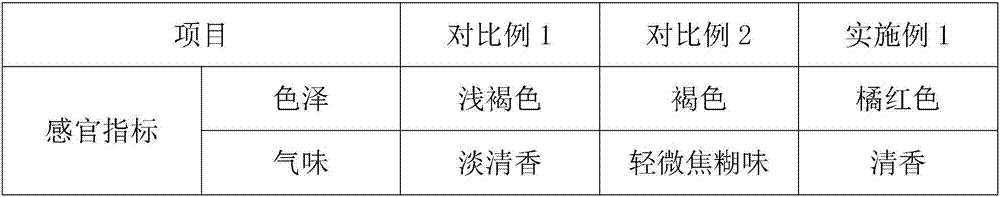

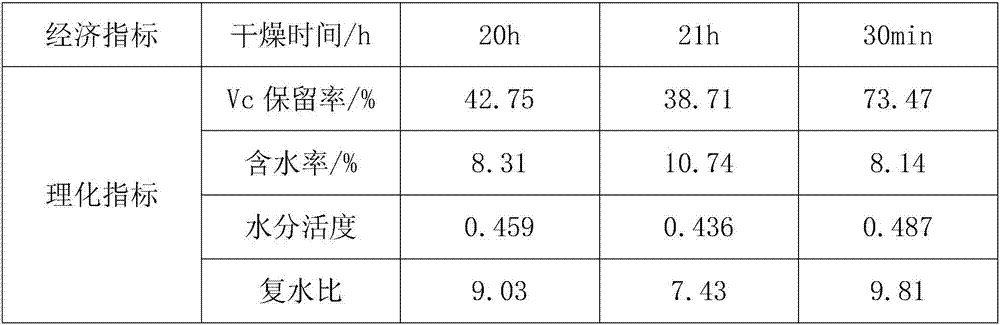

Examples

Embodiment 1

[0019] A preparation method of dehydrated vegetable chips, comprising the following steps:

[0020] S1, select carrots without rot, insect spots, and discoloration and place them in 2-4% saline solution for 30 minutes, then rinse them with water for 2-3 times;

[0021] S2. Cutting the washed vegetables evenly into blocks whose width and length are no more than 5mm;

[0022] S3. Blanch the sliced carrots in a citric acid solution with a mass concentration of 0.25% at a temperature of 90-100° C. for 5 minutes, rinse with water for 2-3 times and cool;

[0023] S4, place the cooled carrots in a centrifuge for dehydration, and drain the water;

[0024] S5. The carrots drained of water are dried by microwave vacuum to obtain partially dehydrated carrots with a moisture content of 20-40%; the process conditions of microwave vacuum drying are that the vacuum pressure is 5MPa, the drying temperature is 40-60°C, and the microwave intensity is 14kW- Drying at 20kW for 30min;

[0025...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com