Resourceful treatment process equipment system for garbage

A treatment process and recycling technology, applied in the field of waste treatment and utilization equipment, can solve the problems of complicated process links and affect the rapidity and scale of waste treatment, so as to improve the gasification efficiency, save the waste sorting link, save money energy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

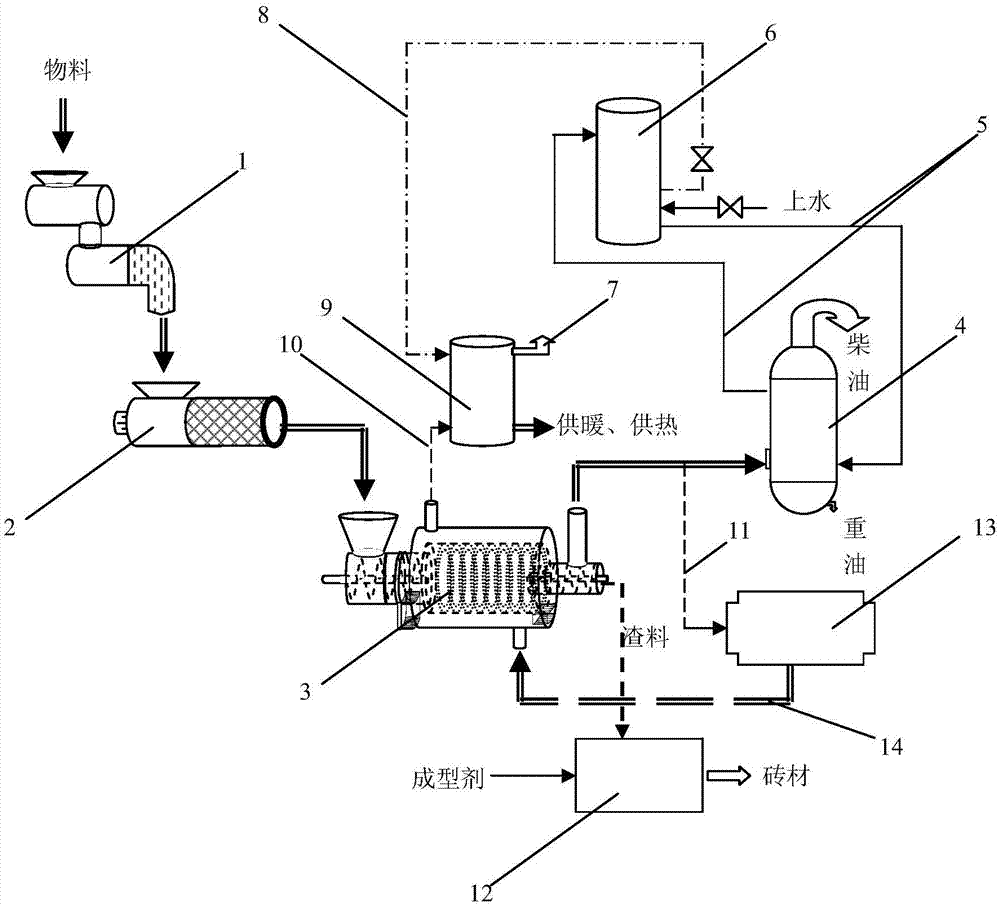

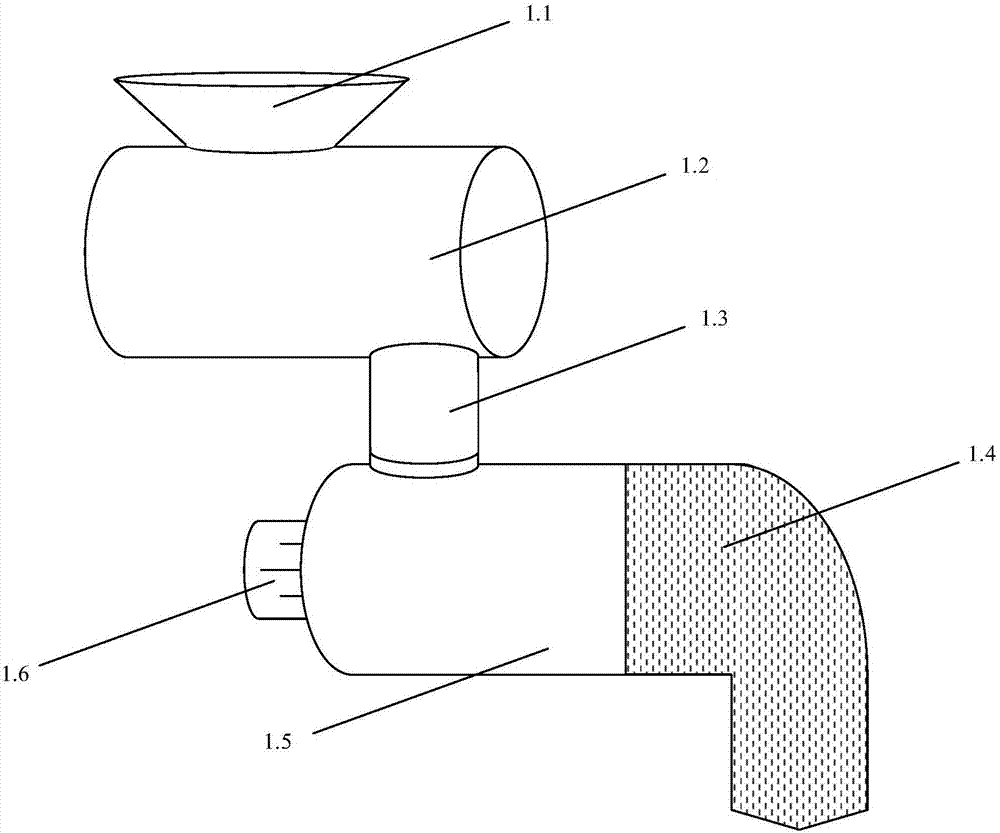

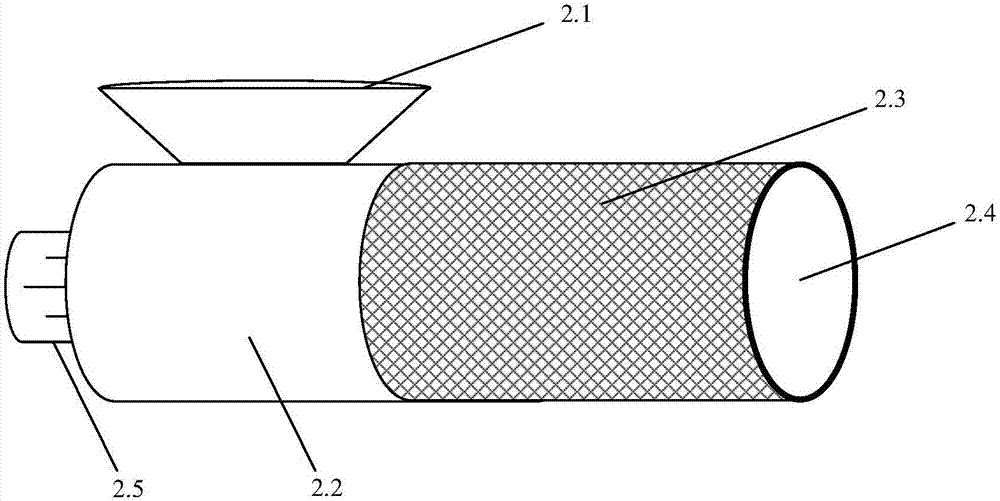

[0019] The process equipment system in this embodiment consists of garbage crusher 1, garbage dehydrator 2, gasification furnace 3, combustion furnace 13, cooling rectification kettle 4, circulating cooling water tank 6, brick making machine 12, heat exchange and heat preservation water tank 9, The gas purification device 7 etc. are composed. The garbage crusher 1 crushes the garbage raw materials, the garbage dehydrator 2 squeezes out the moisture in the garbage, and the gasification furnace 3 relies on the heat generated by the combustion furnace 13 to gasify the garbage raw materials to obtain resource gas, and part of the gas is used as the fuel for the combustion furnace 13. The fuel is sent to the combustion furnace 13 through the gas inlet pipe 11, and the other part is sent to the cooling rectification kettle 4 to obtain diesel oil and heavy o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com