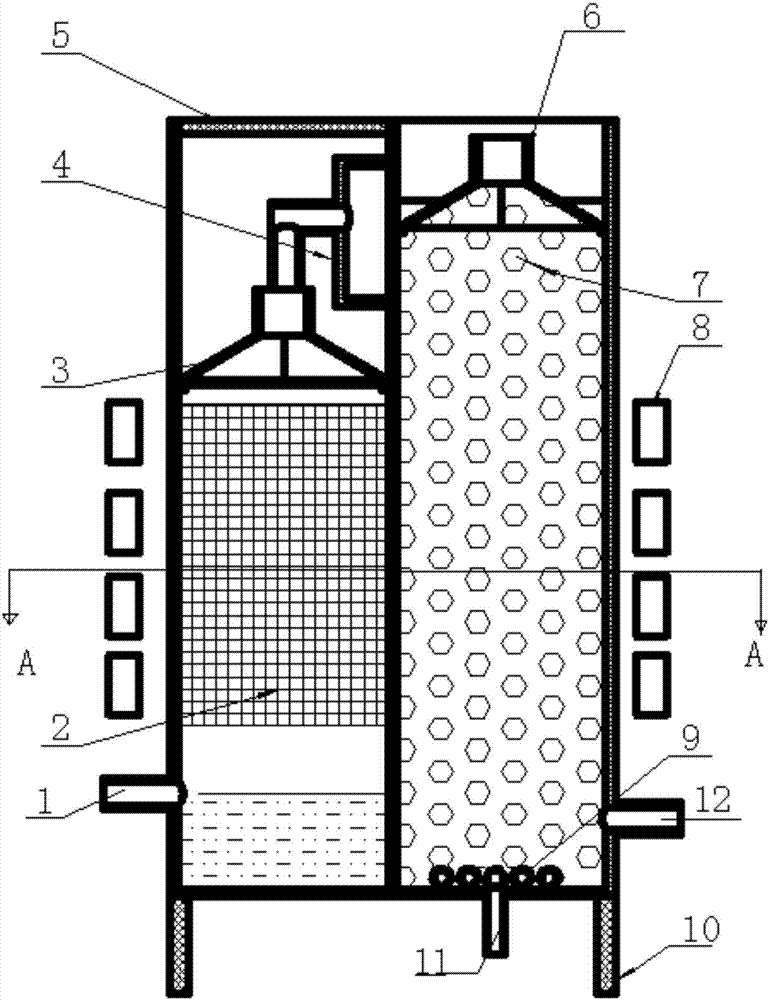

Biological nitrogen removal reactor for sewage and using method thereof

A technology of sewage biology and reactor, which is applied in the direction of chemical instruments and methods, water pollutants, biological water/sewage treatment, etc., can solve the problems of long start-up period, difficult control of reaction conditions, low denitrification efficiency, etc., and achieve convenient and flexible Adjustment, good operation effect, and effect of reducing sludge loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

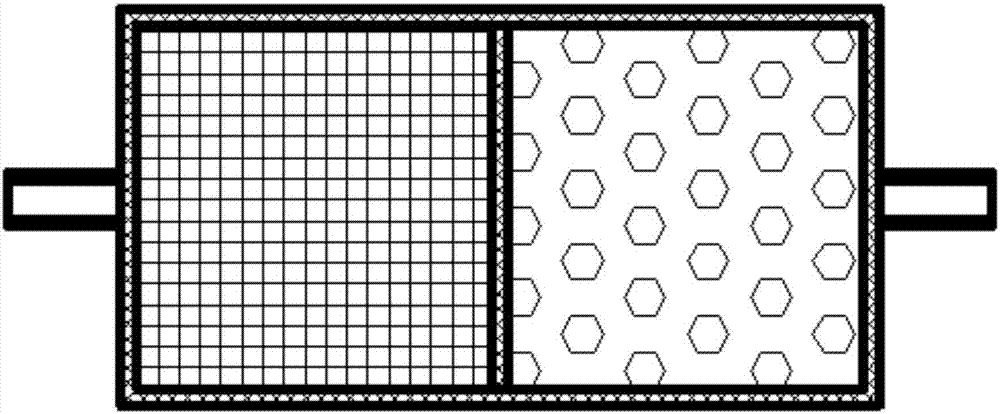

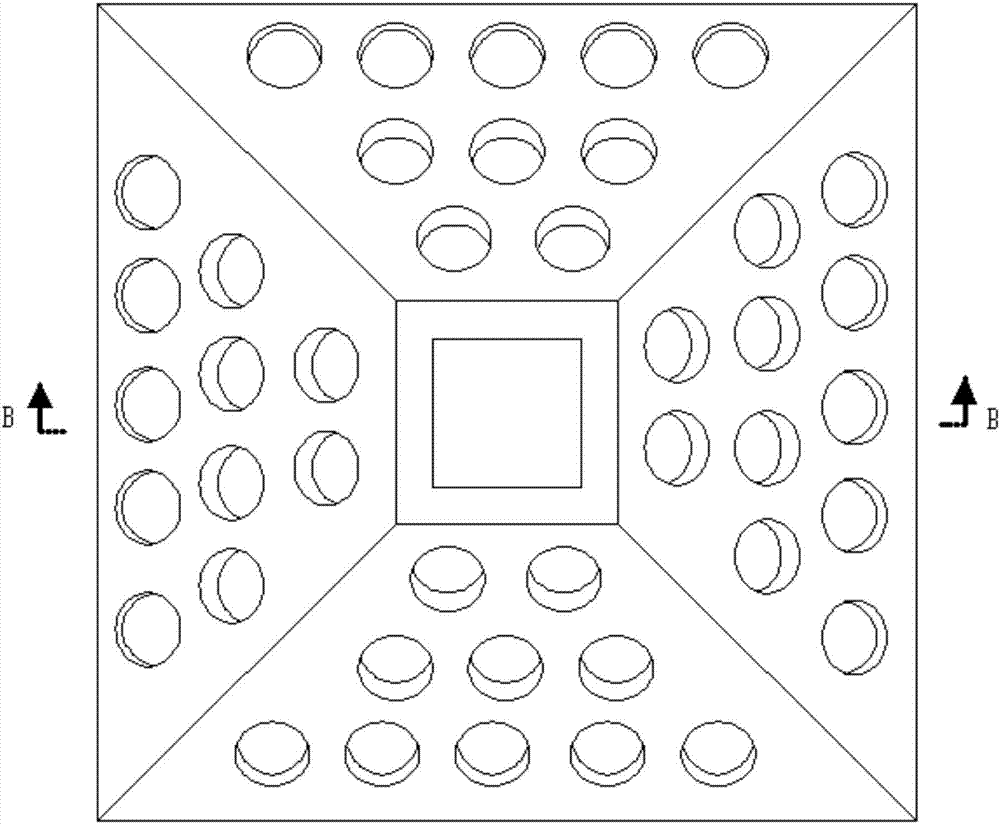

Method used

Image

Examples

Embodiment 2

[0051] Embodiment 2 Reactor operation effect

[0052] Reactor of the present invention moves about 120 days altogether, and the working process of each stage of operation is described below:

[0053] In the first stage (0-50 days), the concentration of ammonia nitrogen in the influent is 50-100mg / L, and the concentration of nitrite nitrogen is 30mg / L. After about 15 days of adaptation period, the ammonia nitrogen (NH 4 + -N), nitrous nitrogen (NO 2 - -N) concentrations were all less than 2mg / L, indicating that AOB bacteria and ANAMMOX bacteria had basically adapted to the environment in the reactor.

[0054] From day 16 onwards, water NH 4 + -N concentration increased to 100mg / L, NO 2 - -N concentration increased to 50mg / L, when the reactor runs to 30 days, the water NH 4 + -N concentration decreased to 8mg / L, indicating that the activities of AOB bacteria and ANAMMOX bacteria in the reactor were basically restored. Within 30 days to 40 days of reactor operation, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| volume ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com