Fine-pitch single IC chip packaging part and preparation method therefor

A technology of chip packaging and details, which is applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc. It can solve problems such as difficulty in controlling the diameter of bonding balls, damage to the previous wire, and short-circuiting of adjacent solder joints. Achieve the effect of avoiding short circuit of adjacent solder joints, reducing the punching rate of plastic packaging, and excellent bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

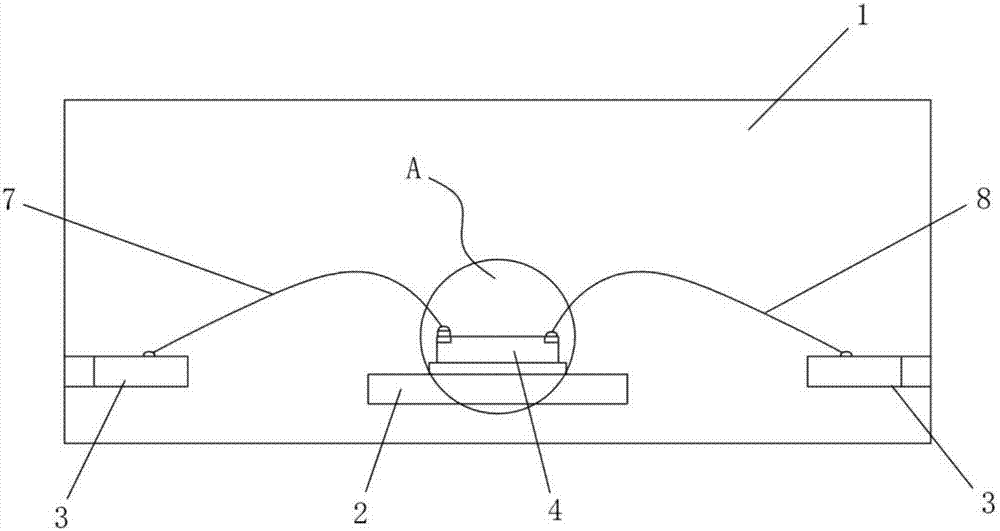

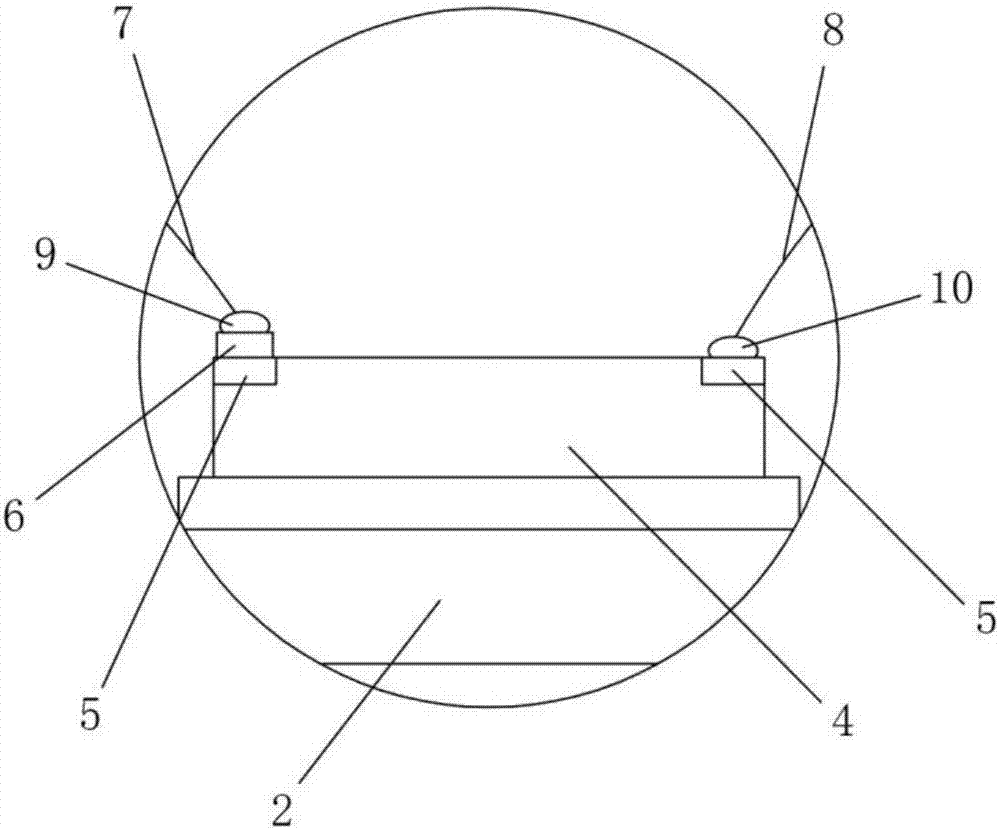

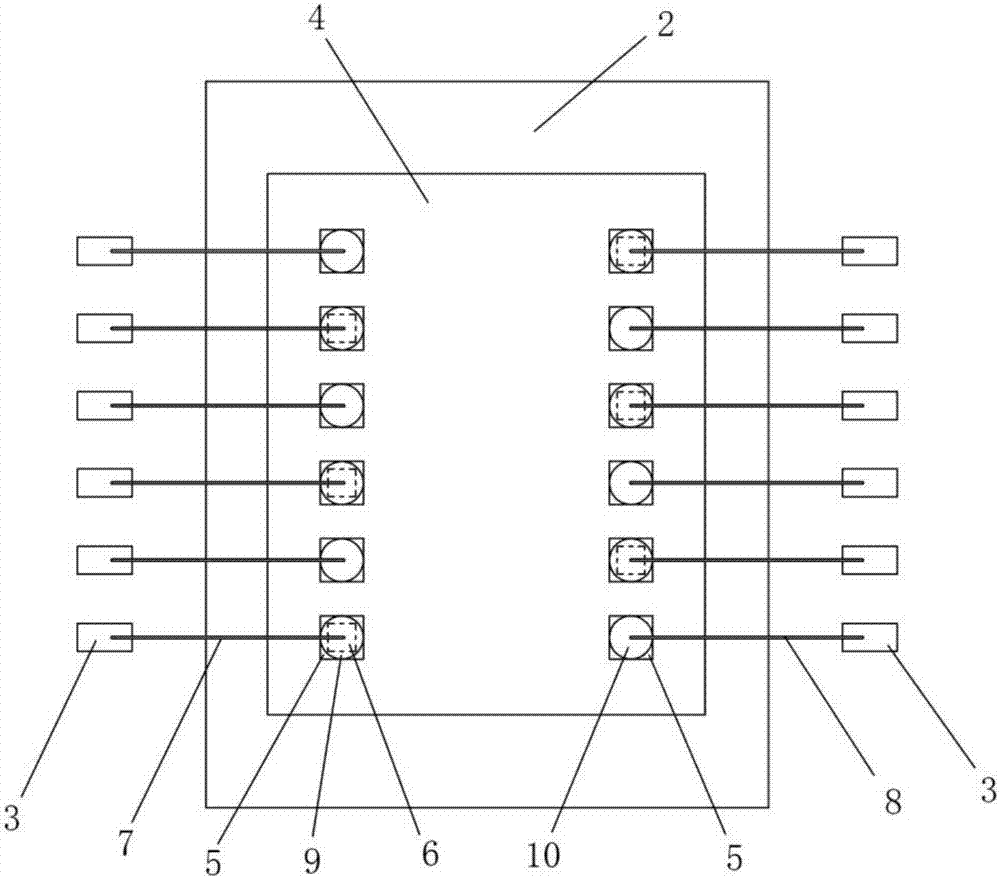

[0033] A kind of fine-pitch single IC chip package of the present invention, its structure is as Figure 1 to Figure 4 shown, by Figure 1 to Figure 4 It can be seen that it mainly includes a plastic package body 1, and a lead frame carrier 2 and a plurality of frame lead inner pins 3 are arranged in the plastic package body 1, and an IC chip 4 is fixed on the upper surface of the lead frame carrier 2 through an adhesive. A plurality of bonding pads 5 are provided on the upper surface of the chip 4 . The pads 5 are arranged in parallel in two rows to form a first pad group and a second pad group. Each pad 5 is respectively connected to a pin 3 in the frame lead through a copper bonding wire. Aluminum electroplating layers 6 are arranged at intervals on the upper surfaces of the plurality of pads 5 in each pad group. The pads 5 provided with the aluminum electroplating layer 6 in one pad group correspond to the positions of the pads 5 not provided with the aluminum electropl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com