Preparation method of spherical gold nanoparticle

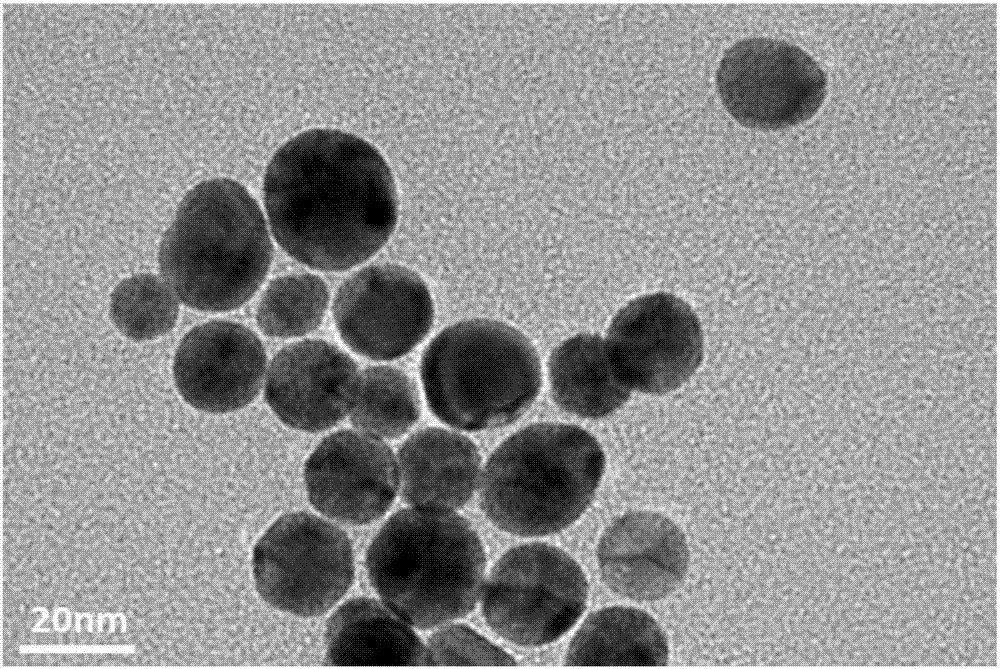

A gold nanoparticle and spherical technology, applied in nanotechnology, metal processing equipment, transportation and packaging, etc., can solve the problems of chemical reagent toxicity, ecological environmental hazards, carcinogenicity, etc., and achieve the effect of simple equipment, low price and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Step 1, dissolving fructose in deionized water to obtain 0.5-1.5 mol / L fructose aqueous solution. In this embodiment, the concentration of the substance amount in the fructose aqueous solution is 1.11 mol / L.

[0025] Step 2, dissolving chloroauric acid crystals in deionized water to form a 0.05-0.12 mol / L chloroauric acid-forming solution. In this embodiment, the concentration of the substance amount in the chloroauric acid aqueous solution is 0.1 mol / L.

[0026] Step 3, washing the glass container used, and rinsing it with deionized water.

[0027] Step 4: inject 25 mL of fructose aqueous solution into the flask, heat to boiling, and keep boiling for 5-15 minutes. In this embodiment, the time to keep the fructose aqueous solution boiling is 15 minutes.

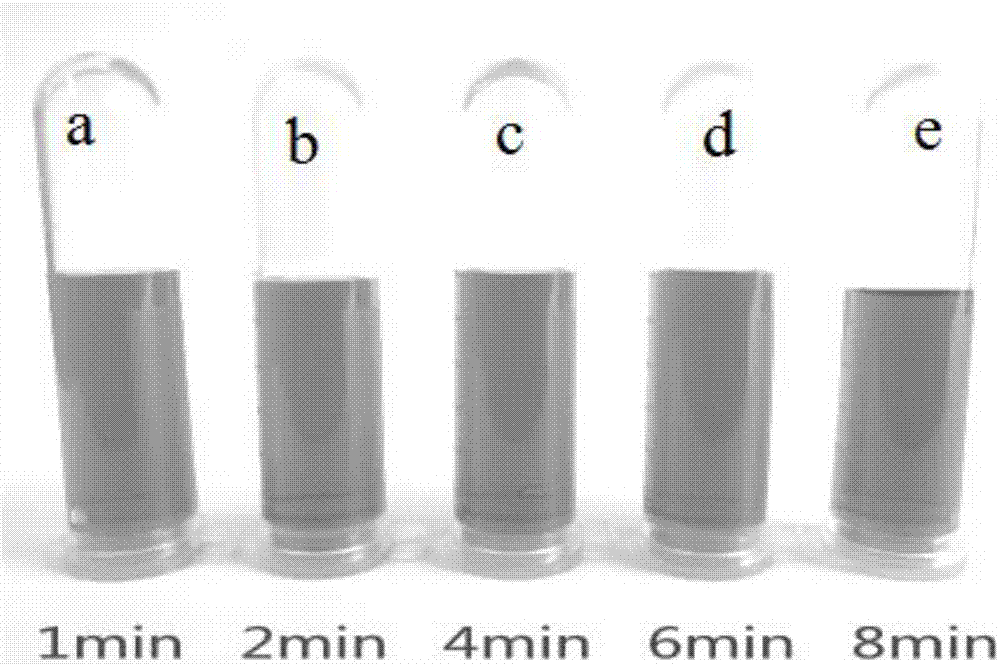

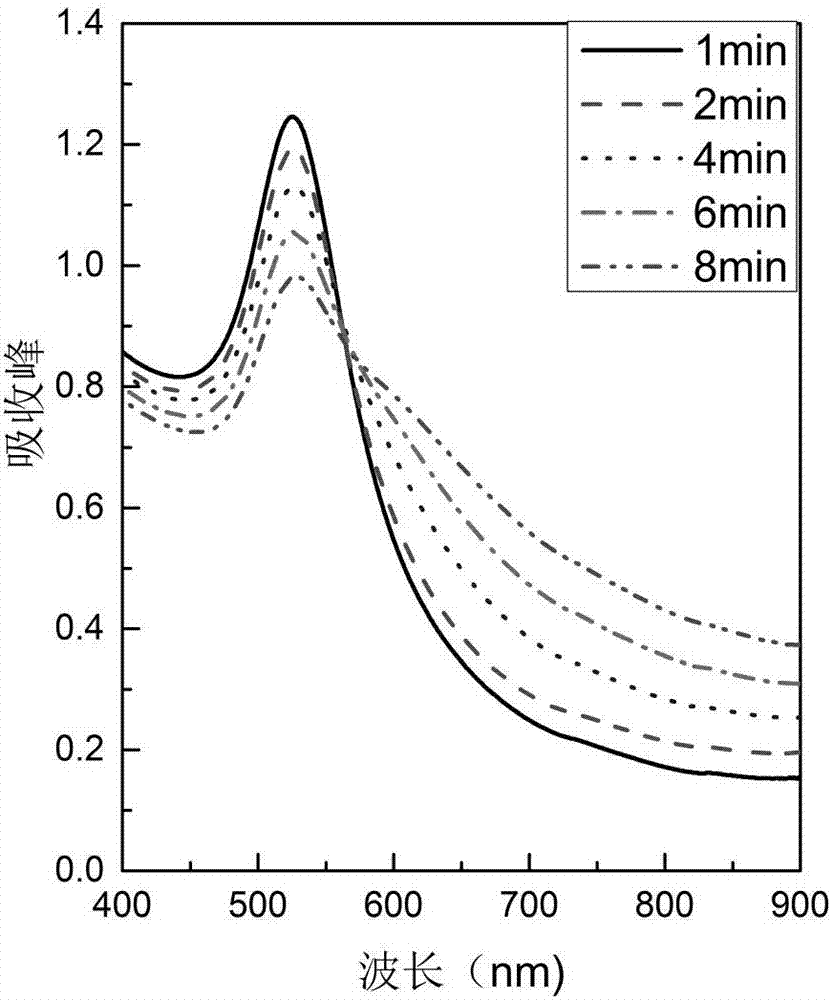

[0028] Step 5: In boiling state, add 80 μL of chloroauric acid solution, react for 5-10 minutes, and keep the pH value of the reaction system between 4.0 and 5.5. In this embodiment, the pH value of the reaction sy...

Embodiment 2

[0043]Step 1, dissolving fructose in deionized water to obtain 0.5-1.5 mol / L fructose aqueous solution. In this embodiment, the concentration of the substance amount in the fructose aqueous solution is 1.11 mol / L.

[0044] Step 2, dissolving chloroauric acid crystals in deionized water to form a 0.05-0.12 mol / L chloroauric acid-forming solution. In this embodiment, the concentration of the substance amount in the chloroauric acid aqueous solution is 0.1 mol / L.

[0045] Step 3, washing the glass container used, and rinsing it with deionized water.

[0046] Step 4: inject 25 mL of fructose aqueous solution into the flask, heat to boiling, and keep boiling for 5-15 minutes. In this embodiment, the time to keep the fructose aqueous solution boiling is 15 minutes.

[0047] Step 5, in boiling state, add 160 μL of chloroauric acid solution, react for 5-10 minutes, and keep the pH value of the reaction system between 4.0 and 5.5. In this embodiment, the pH value of the reaction sy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com