Screw-thread steel derusting machine

A technology of derusting machine and rebar, which is applied in the direction of grinding machine tool parts, grinding feed movement, grinding machine, etc., which can solve the problem of labor intensity of manual derusting of rebar, insufficient derusting effect and low operation efficiency, etc. Problems can be improved to improve operating efficiency, prevent dust splashing, and save labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

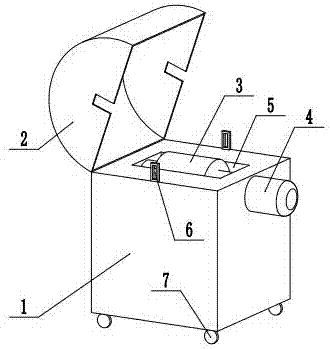

[0013] A threaded steel derusting machine, such as figure 1 As shown, it includes a derusting machine body 1, the body 1 is a cube, the body 1 is hollow, and a rectangular groove 5 is opened on the top, the inside of the body 1 is equipped with a wire drawing drum 3, and the wire drawing drum 3 is high 3-5 cm out of the rectangular groove, the wire drawing drum 3 is connected to the motor 4 on the outside of the body 1 . A protective cover 2 is installed on the top of the main body 1, and the protective cover 2 is semicircular and rotatably hinged to one side of the main body 1 through a flat hinge. The two sides of the main body 1 parallel to the drawing drum 3 are respectively provided with a detachable limit card slot 6, which is suitable for various specifications of rebar, and the lower part of the main body 1 is provided with four unive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com