Preparation method of high-purity climbazole

A kind of Clambol, high-purity technology, applied in the field of preparation of high-purity Clambol, can solve the problems of high production cost, rising production cost, etc., achieves low production cost, high product quality, and promotes the effect of positive process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

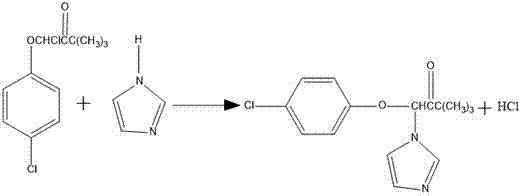

Image

Examples

Embodiment 1

[0014] Dissolve 100kg of chloroetherketone, 30kg of imidazole and 7kg of N,N-dimethylbenzamide in 200kg of toluene, and react at ℃ for 3 hours. After the reaction, add 80 kg of water to wash at 60° C., stand still to separate the water, then cool down to 30° C., crystallize and separate to obtain the crude campanolin. Put 100kg of crude campanola into 200kg of toluene, raise the temperature to 80°C to fully dissolve, add 2kg of activated carbon for press filtration, cool to 30°C to crystallize after press filtration, and then centrifuge to obtain the high-quality clambasu, which is then dried at 65°C. For white crystals. The purity by gas chromatography analysis is 99.92%.

Embodiment 2

[0016] Dissolve 100kg of chloroetherketone, 50kg of imidazole and 10kg of N,N-dimethylbenzamide in 250kg of toluene, and react at 105°C for 4 hours. After the reaction, add 90 kg of water to wash at 55°C, let stand to separate the water, then lower the temperature to 32°C, crystallize and separate to obtain the crude campanolin. Put 100kg of crude campanolin into 270kg of toluene, and heat up to 85°C to fully dissolve. Add 8 mass kg of 30wt.% liquid caustic soda to the toluene to wash, then add 200 mass kg of water to wash, add 3 kg of activated carbon after water separation, press filter, cool to 34 °C to crystallize after press filtration, and then centrifuge to obtain the high-quality clambaosu. Dry the high-quality Campanola at 70°C to obtain white crystals, and the purity is 99.96% by gas chromatography.

Embodiment 3

[0018] Dissolve 100kg of chloroetherketone, 70kg of imidazole and 12kg of N,N-dimethylbenzamide in 300kg of toluene, and react at 105°C for 5 hours. After the reaction, add 100 kg of water to wash at 56°C, let stand to separate the water, then lower the temperature to 35°C, crystallize and separate to obtain crude campanolin. Put 100kg of crude clambasu into 400kg of toluene, raise the temperature to 87°C, fully dissolve, add 3kg of activated carbon for pressure filtration, cool to 35°C to crystallize after press filtration, and then centrifuge to obtain the high-quality climbanol, which is then dried at 73°C , as off-white crystals, the purity of which was analyzed by gas chromatography was 99.91%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com