Hydrogasification coke discharging and cooling system and technology

A technology of hydrogenation, gasification and cooling system, applied in gasification process, coke oven, petroleum industry and other directions, can solve the problems of high temperature light and fine solid particles unable to fluidize normally, poor heat exchange effect and short residence time, etc. The effect of easy operation, efficient recovery and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

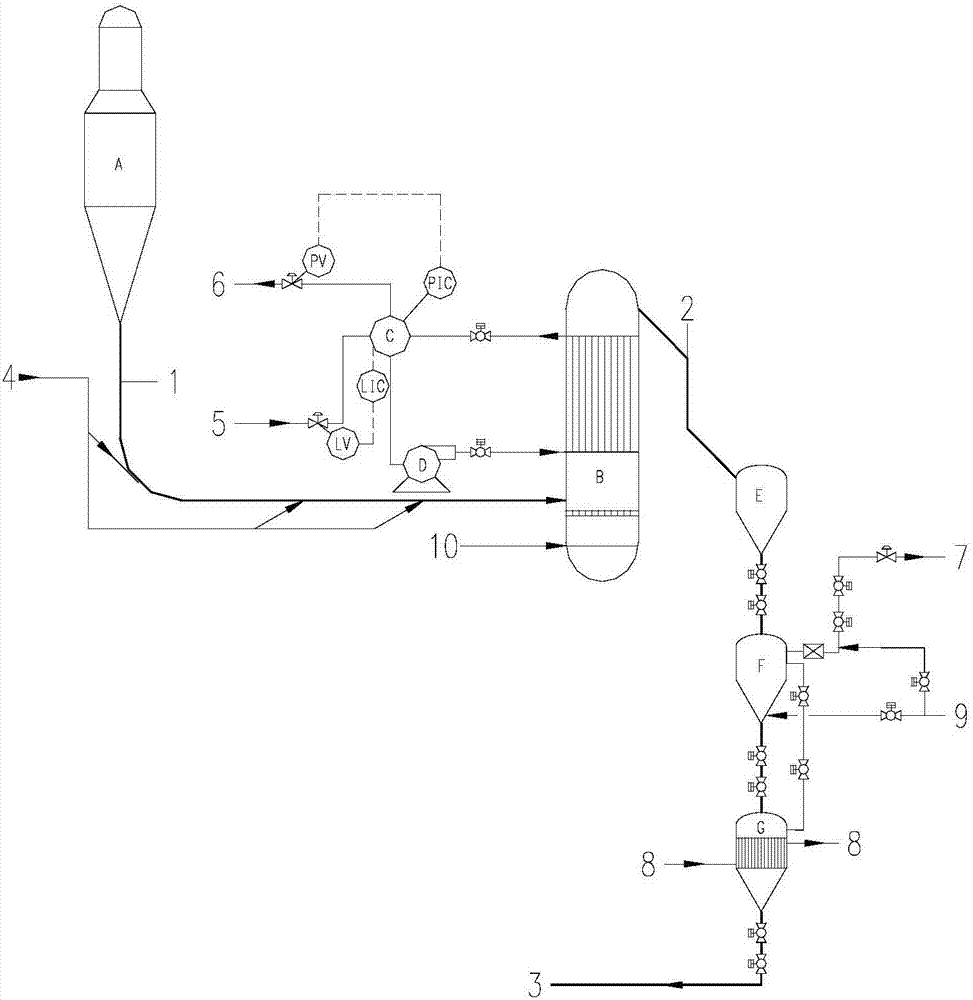

[0029] See attached picture.

[0030] A hydrogenation gasification coke discharge cooling system, including a hydrogenation gasification furnace A, a semi-coke cooling fluidized bed B, a fluidized bed steam drum C, a fluidized bed circulation pump D, a semi-coke collection tank E, and a semi-coke lock hopper The cooling system composed of F and semi-coke cooler G is characterized in that: the semi-coke produced by the hydrogenation gasifier A is sent to the lower part of the semi-coke cooling fluidized bed B through dense phase transportation, and the semi-coke is cooled and fluidized The bottom of the bed B is provided with a wind cap, and the semi-coke is passed into the semi-coke cooling fluidized bed above the wind cap, and the semi-coke cooling fluidized bed has a built-in cooling water pipe, and the semi-coke cooling fluidized bed below the wind cap Through the fluidization gas, the cooled semi-coke is pushed to the upper outlet of the semi-coke cooling fluidized bed to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com