Novel track pin shaft material and heat treatment technology thereof

A crawler pin, a new type of technology, applied in the field of machinery and equipment manufacturing, can solve the problems of easy brittle fracture, increased material cost, no promotion value, etc., and achieves the effect of high stability and improved toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

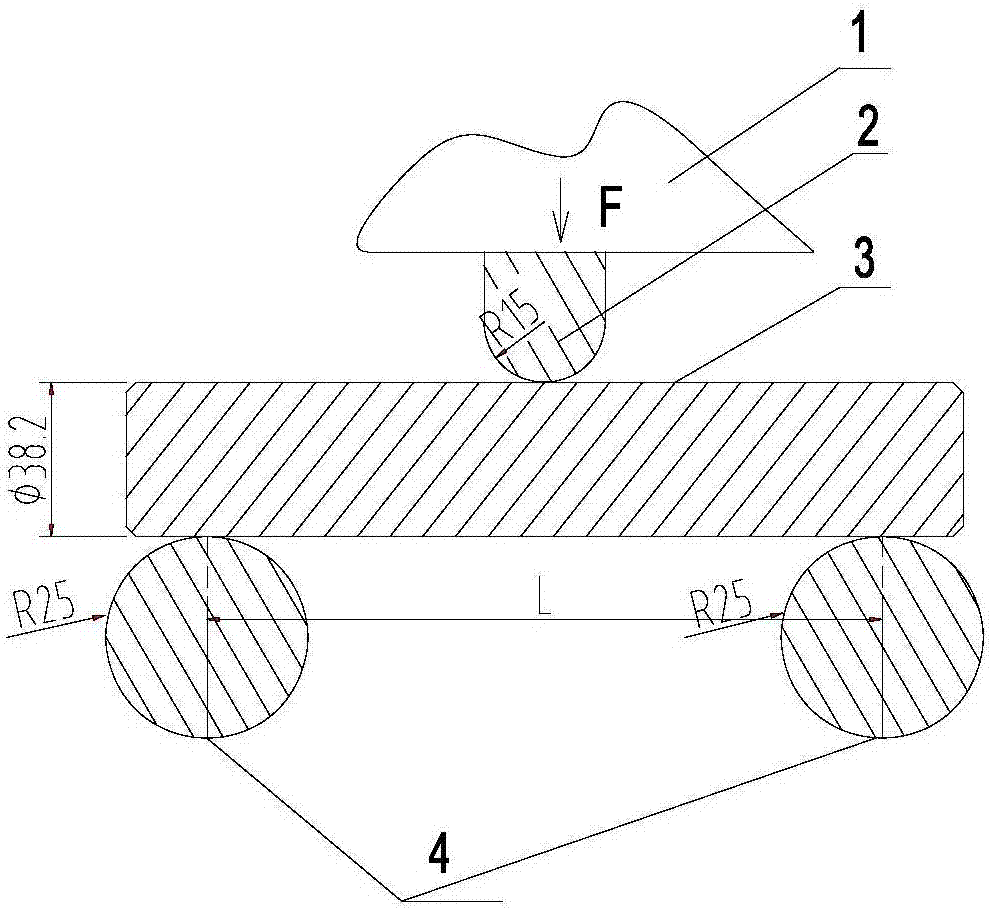

Method used

Image

Examples

Embodiment 1

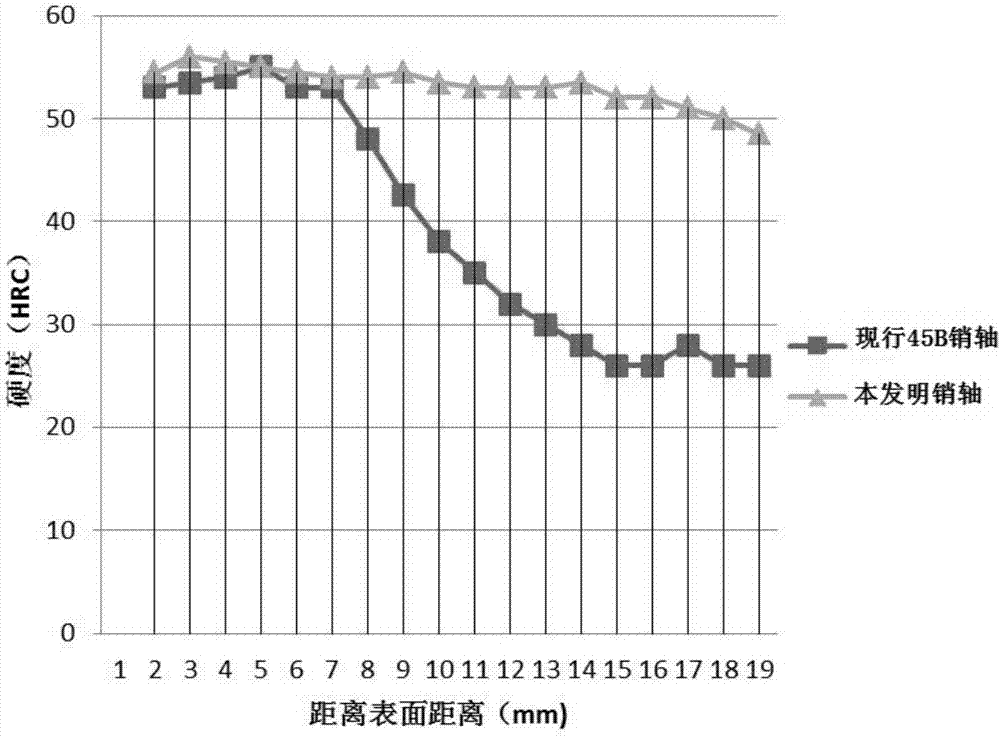

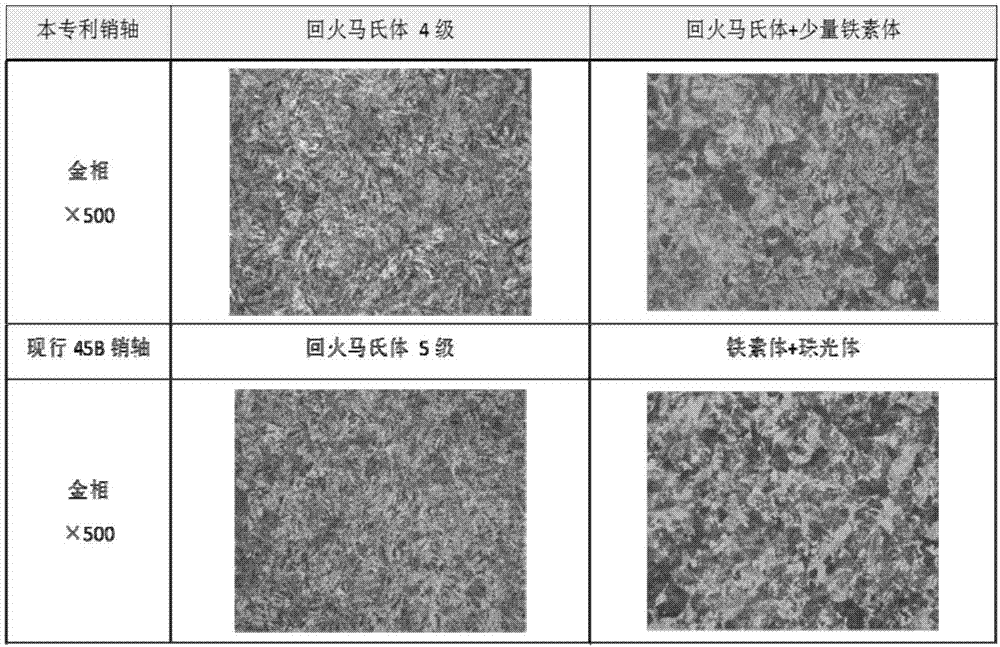

[0031] Example 1: A new type of track pin new material, the furnace number of the material is 17702424, and its chemical composition is: C: 0.34%, Si: 0.31%, Mn: 1.2%, P: 0.012%, S: 0.01%, Cr: 0.22%, Ni: 0.02%, Cu: 0.04%, B: 0.0019%, Al: 0.03%, Ti: 0.037%, Mo: 0.02%, Ti / Ni: 9.7; surface quenching core Hardness 55HRC, surface hardness 46.5HRC.

Embodiment 2

[0032] Example 2: A new type of track pin new material, the furnace number of the material is 17702425, and its chemical composition is: C: 0.33%, Si: 0.27%, Mn: 1.19%, P: 0.012%, S : 0.01%, Cr: 0.22%, Ni: 0.04%, Cu: 0.05%, B: 0.0018%, Al: 0.03%, Ti: 0.038, Mo: 0.03%, Ti / Ni: 10; surface quenching core hardness 55.5 HRC, surface hardness 48.5HRC.

Embodiment 3

[0033]Example 3: A new type of track pin new material, the furnace number of the material is 17702427, and its chemical composition is: C: 0.34%, Si: 0.30%, Mn: 1.18%, P: 0.012%, S : 0.01%, Cr: 0.23%, Ni: ≤0.02%, Cu: 0.04%, B: 0.0021%, Al: 0.031%, Ti: 0.040%, Mo: ≤0.02%, Ti / Ni: 9.5; surface quenching core Internal hardness 55HRC, surface hardness: 48HRC.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com