Flexible air-permeable pressure sensor based on friction nano-generator and fabrication thereof

A pressure sensor and nanogenerator technology, applied in sensors, lamination, electrospinning, etc., can solve problems such as difficulty in meeting the needs of wearable human physiological signal monitoring, inability to meet human pulse measurement, lack of flexibility and breathability, etc. , to achieve the effect of ensuring comfort, wide application space and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

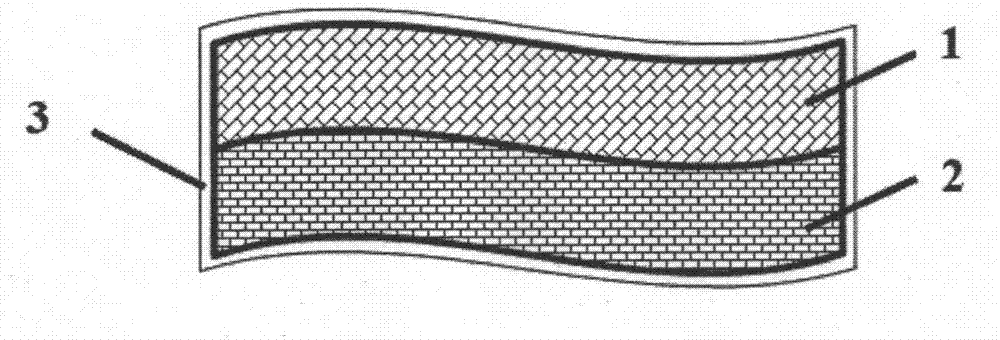

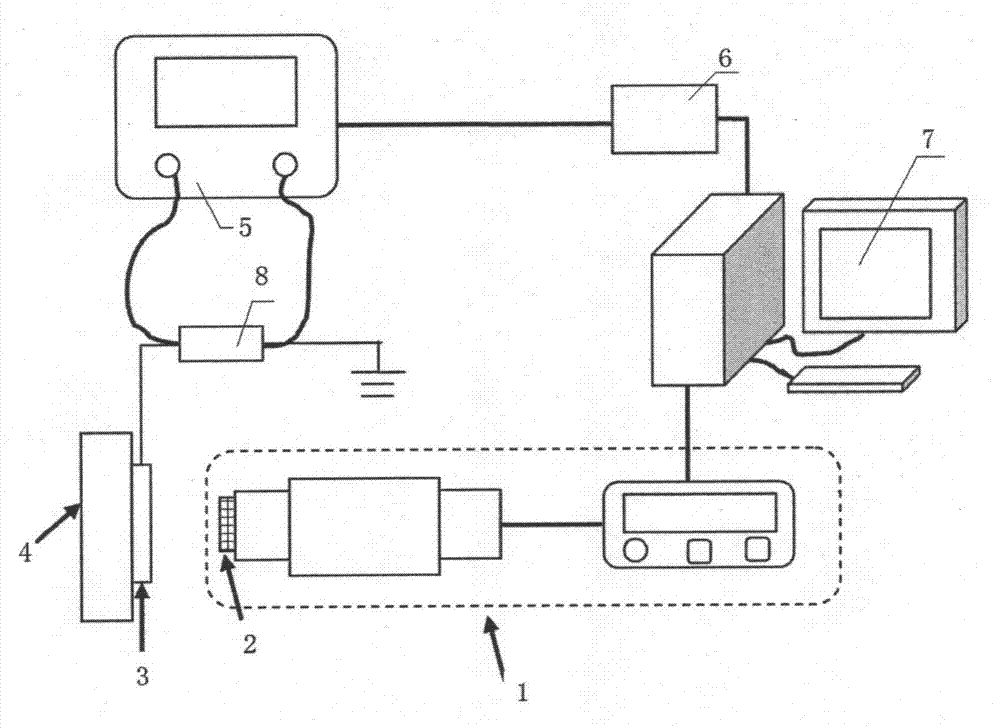

[0039] A gas-permeable flexible pressure sensor based on a triboelectric nanogenerator, including a flexible carbon nanofiber film and a nanofiber film obtained by electrospinning on it, and the flexible carbon nanofiber film is obtained by electrospinning Nanoparticle-doped fiber films were obtained by carbonization. The preparation method of the air-permeable flexible pressure sensor based on the triboelectric nanogenerator is as follows:

[0040] Step 1: Add 6g of polyvinylidene fluoride (with a weight average molecular weight of 570,000) into 24g of N,N-dimethylformamide solvent, and stir in a water bath at 80°C for 10 hours to form a uniform and stable solution. After it was naturally cooled to room temperature, it was added to an electrospinning device for electrospinning to prepare a nanofiber film with a thickness of 30 μm. The spinning parameters were: voltage 30kV, receiving distance 25cm, perfusion speed 2mL / h, temperature 25°C , relative humidity 45%.

[0041] Th...

Embodiment 2

[0046] A gas-permeable flexible pressure sensor based on a triboelectric nanogenerator, including a flexible carbon nanofiber film and a nanofiber film obtained by electrospinning on it, and the flexible carbon nanofiber film is obtained by electrospinning Nanoparticle-doped fiber films were obtained by carbonization. The preparation method of the air-permeable flexible pressure sensor based on the triboelectric nanogenerator is as follows:

[0047] Step 1: Add 4.5g of polyvinylidene fluoride-trifluoroethylene (weight average molecular weight: 470,000 to 570,000) into 25.5g of N,N-dimethylformamide solvent, and stir in a water bath at 80°C for 12 hours to form Uniform and stable solution. After it was naturally cooled to room temperature, it was added to an electrospinning device for electrospinning to prepare a nanofiber film with a thickness of 20 μm. The spinning parameters were: voltage 10 kV, receiving distance 15 cm, perfusion speed 1.44 mL / h, temperature 25 ℃, relativ...

Embodiment 3

[0053] A gas-permeable flexible pressure sensor based on a triboelectric nanogenerator, including a flexible carbon nanofiber film and a nanofiber film obtained by electrospinning on it, and the flexible carbon nanofiber film is obtained by electrospinning Nanoparticle-doped fiber films were obtained by carbonization. The preparation method of the air-permeable flexible pressure sensor based on the triboelectric nanogenerator is as follows:

[0054] Step 1: Add 10.5 g of polystyrene (weight-average molecular weight: 190,000) into 19.5 g of tetrahydrofuran solvent, and stir at room temperature of 25° C. for 12 h to form a uniform and stable solution. Then it was added to the electrospinning device for electrospinning to prepare a nanofiber film with a thickness of 50 μm. The spinning parameters were: voltage 10kV, receiving distance 35cm, perfusion speed 0.42mL / h, temperature 25°C, relative humidity 45%. .

[0055] The second step: 6.0g polyvinylpyrrolidone (weight-average mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Gas transmission rate | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com