Fiber-based shape adaptive passive electronic skin and preparation method thereof

An adaptive, electronic skin technology, which is applied in the measurement of the properties and forces of piezoelectric resistive materials, can solve the problems that it is difficult to achieve a high degree of self-adaption in the shape of the electronic skin, affecting the wearing comfort of the human body, and inconvenient to replace the battery. , to achieve the effect of shape adaptability, excellent flexibility and avoiding discomfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

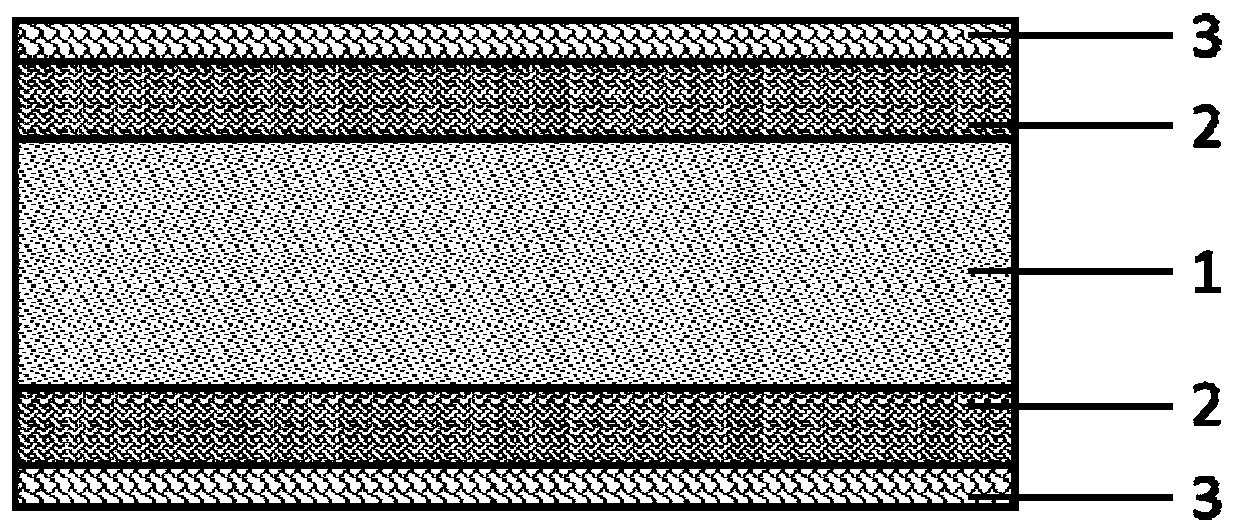

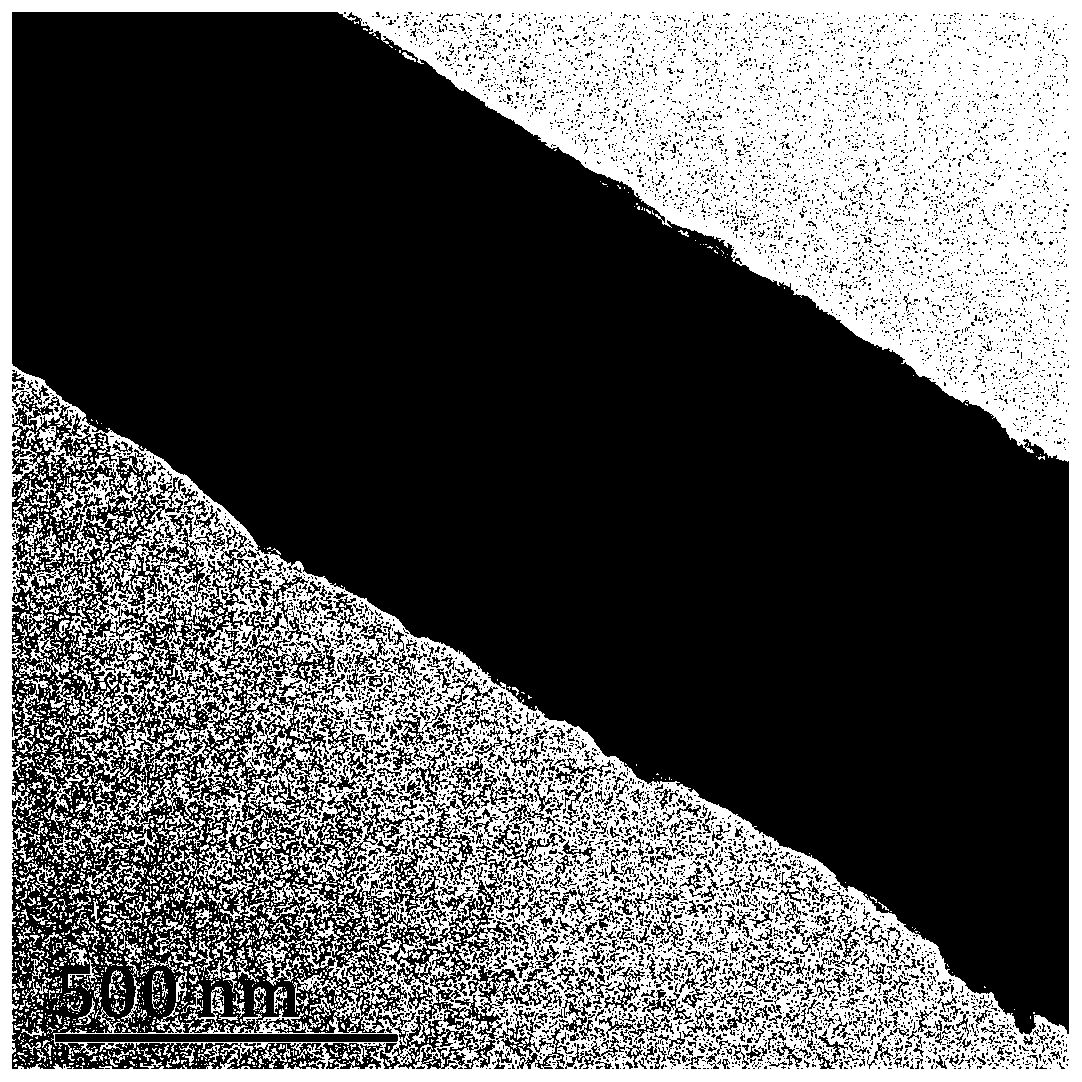

[0046] A fiber-based highly adaptive passive electronic skin based on the piezoelectric effect, including a flexible coaxial piezoelectric nanofiber membrane prepared by a one-step coaxial electrospinning technique, the upper side of the flexible coaxial piezoelectric nanofiber membrane The flexible conductive fabric electrodes are arranged on the lower side and the lower side, and the flexible coaxial piezoelectric nanofiber film and the flexible conductive fabric electrodes are arranged in the transparent packaging material. The thickness of the flexible conductive fabric electrode is 35 μm, and the thickness of the transparent packaging material is 70 μm.

[0047] The preparation method of the above-mentioned fiber-based highly adaptive passive electronic skin is as follows:

[0048] Step 1: Add 100mg of graphene (diameter<40nm) into a mixed solvent of 26g N,N-dimethylformamide and 19g acetone, and perform ultrasonic dispersion at room temperature (25°C) and 300W 2 hours t...

Embodiment 2

[0054] A fiber-based highly adaptive passive electronic skin based on the piezoelectric effect, including a flexible coaxial piezoelectric nanofiber membrane prepared by a one-step coaxial electrospinning technique, the upper side of the flexible coaxial piezoelectric nanofiber membrane The flexible conductive fabric electrodes are arranged on the lower side and the lower side, and the flexible coaxial piezoelectric nanofiber film and the flexible conductive fabric electrodes are arranged in the transparent packaging material. The thickness of the flexible conductive fabric electrode is 30 μm, and the thickness of the transparent packaging material is 100 μm.

[0055] The preparation method of the above-mentioned fiber-based highly adaptive passive electronic skin is as follows:

[0056] Step 1: Add 150mg of carbon nanotubes (diameter<20nm) to 50g of N,N-dimethylformamide, ultrasonically disperse at room temperature (25°C) and 300W for 2 hours to form a uniform and stable firs...

Embodiment 3

[0061] A fiber-based highly adaptive passive electronic skin based on the piezoelectric effect, including a flexible coaxial piezoelectric nanofiber membrane prepared by a one-step coaxial electrospinning technique, the upper side of the flexible coaxial piezoelectric nanofiber membrane The flexible conductive fabric electrodes are arranged on the lower side and the lower side, and the flexible coaxial piezoelectric nanofiber film and the flexible conductive fabric electrodes are arranged in the transparent packaging material. The thickness of the flexible conductive fabric electrode is 40 μm, and the thickness of the transparent packaging material is 90 μm.

[0062] The preparation method of the above-mentioned fiber-based highly adaptive passive electronic skin is as follows:

[0063] Step 1: Add 70mg of silver nanowires (diameter<10nm) to a mixed solvent of 28g N,N-dimethylformamide and 20g acetone, and perform ultrasonic dispersion at room temperature (25°C) and 300W 2 ho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com