Composite reinforcing agent and preparation method thereof, and reinforcing method of aged paper

A technology of reinforcing agent and paper, which is applied in the direction of adding anti-aging agent for paper, textiles and papermaking, papermaking, etc. It can solve the problems of mechanical strength reduction, mechanical strength reduction, paper discoloration, etc., and achieve mechanical properties. Enhanced mechanical properties, raw materials sufficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

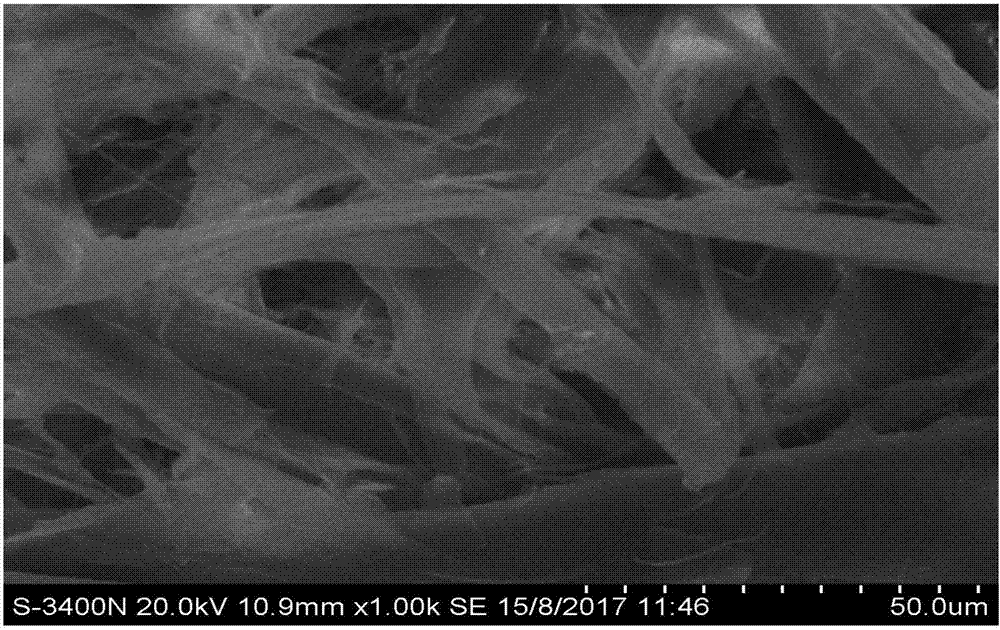

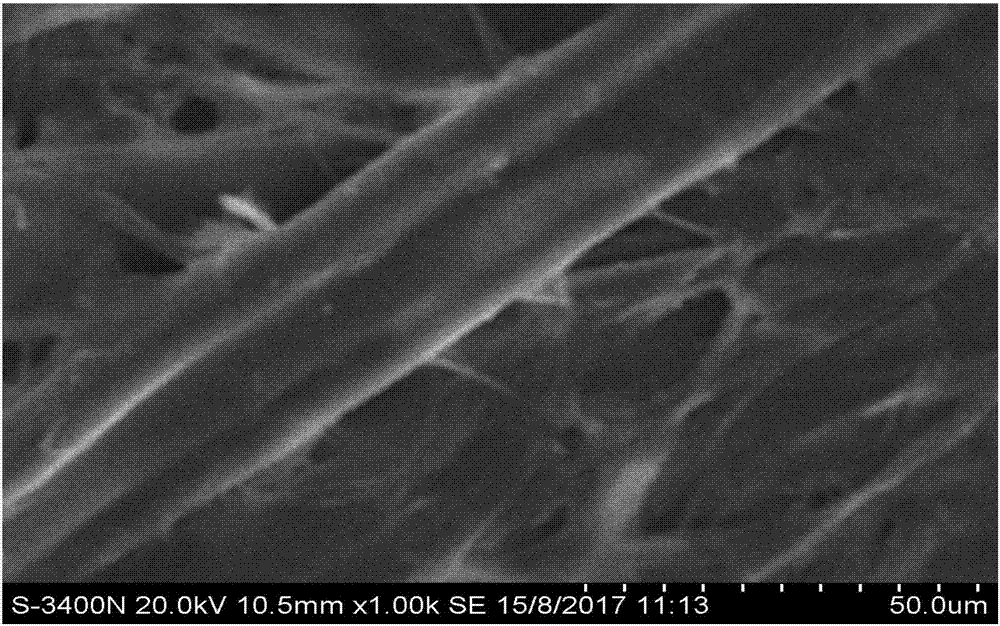

Image

Examples

preparation example Construction

[0053]The present invention also provides a preparation method of the composite reinforcing agent described in the above technical solution, comprising the following steps:

[0054] A) cationic starch is mixed with the solvent of the first amount to obtain a cationic starch solution;

[0055] b) cationic guar gum, the solvent of the second consumption and cosolvent are mixed to obtain cationic guar gum solution;

[0056] c) adding the cationic guar gum solution to the cationic starch solution and mixing to obtain a composite reinforcing agent.

[0057] In the present invention, the cationic starch is first mixed with the first amount of solvent to obtain a cationic starch solution. In the present invention, the cationic starch is the same as that described in the above technical solutions, and details are not repeated here. In the present invention, the solvent in the first amount is a part of the solvent in the above technical solution. In the present invention, the mass r...

Embodiment 1

[0075] (1) Accurately measure 49.75g of absolute ethanol and 49.75g of distilled water into a beaker, then add 0.5g of cationic starch, fully stir and mix to obtain a cationic starch solution, and place it in a sealed container to prevent volatilization from exposure to the air; then , accurately measure 44.75g of absolute ethanol, 44.75g of distilled water and 10g of betaine into a beaker, then add 0.5g of cationic guar gum, fully stir and mix to obtain a cationic guar gum solution; then pour the above cationic guar gum solution into into the previously prepared cationic starch solution, fully stirring and mixing to obtain a composite reinforcing agent.

[0076] (2) Put the composite reinforcing agent obtained in step (1) in a sealed container, directly apply a brush to the paper to be treated, and apply repeatedly at 25°C (after each application of the composite reinforcing agent volatilizes, the number of applications is 4 times) After 13 minutes, the paper coated with the ...

Embodiment 2

[0083] (1) Accurately measure 49.625g of absolute ethanol and 49.625g of distilled water into a beaker, then add 0.75g of cationic starch, fully stir and mix to obtain a cationic starch solution, and place it in a sealed container to prevent volatilization from exposure to the air; then , accurately measure 44.625g of absolute ethanol, 44.625g of distilled water and 10g of betaine into a beaker, then add 0.75g of cationic guar gum, fully stir and mix to obtain a cationic guar gum solution; then pour the above cationic guar gum solution into into the previously prepared cationic starch solution, fully stirring and mixing to obtain a composite reinforcing agent.

[0084] (2) Put the composite reinforcing agent obtained in step (1) in a sealed container, directly apply a brush to the paper to be treated, and apply repeatedly at 25°C (after each application of the composite reinforcing agent volatilizes, the number of applications is 4 times) After 12 minutes, the paper coated wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com